Heat collecting board achieving flow channel same-stroke constant pressure distribution

A heat collecting plate and flow channel technology, applied in the field of heat collecting devices, can solve the problems of low heat collecting efficiency, uneven distribution of working fluid in the flow channel, sparse flow channels of the heat collecting plate, etc., so as to avoid the phenomenon of liquid hammer and improve the heat concentration effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

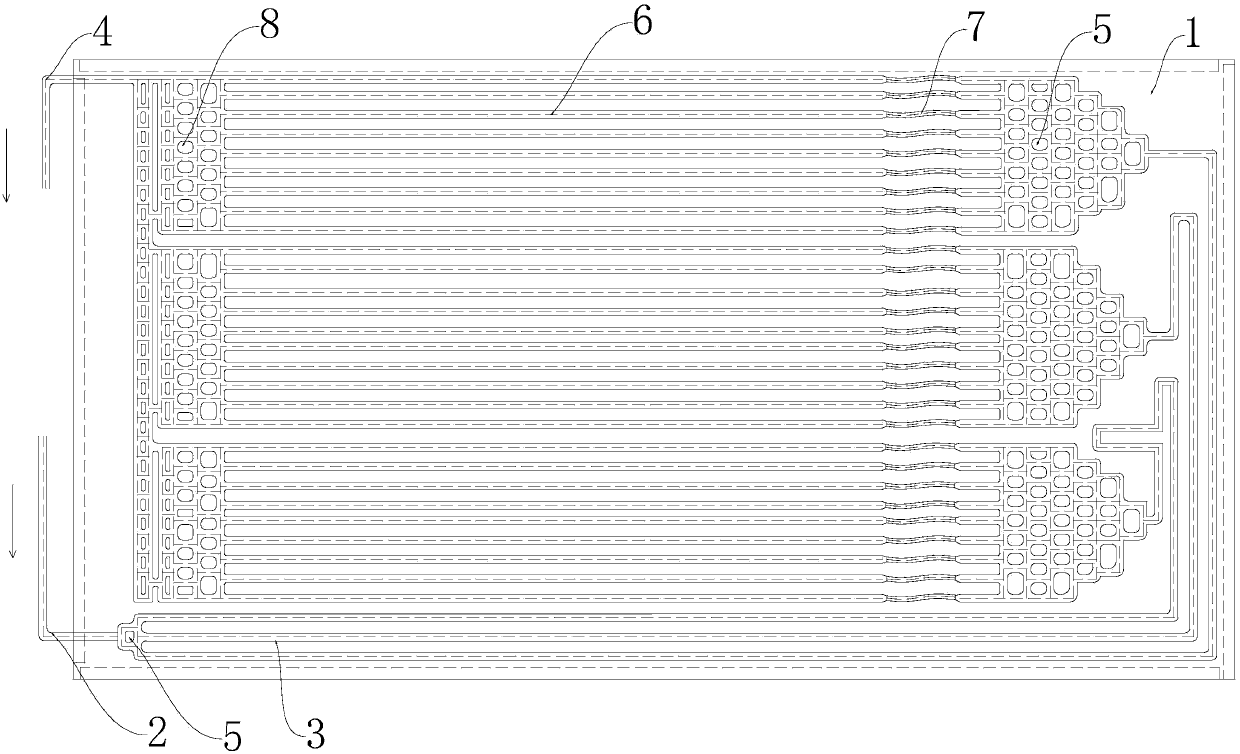

[0021] Such as figure 1 As shown, the heat collecting plate described in this embodiment has flow passages with equal pressure distribution, which includes a plate body 1 and a working fluid flow channel formed inside the plate body 1, and the working fluid flow channel includes a main flow channel 3 and a branch flow Channel 6, the main flow channel inlet 2 and the main flow channel outlet 4 are arranged on the plate body 1, and the main flow channel inlet 2 is connected with three main channels 3 through the same process flow divider 5, and the flow of each main channel 3 is the same, The other end of each main flow channel 3 is connected with 10 branch flow channels 6 through the same process flow divider 5, and the flow process of each branch flow channel 6 is the same, and each branch flow channel 6 is provided with a diameter-reducing section 7, each diameter-reducing section The length and diameter of 7 are the same, and the reduced-diameter section 7 is arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com