A method and device for measuring film thickness

A layer thickness and film layer technology, applied in the field of film thickness measurement, can solve the problems of inaccurate thickness data, inconvenient film thickness measurement, and data accuracy impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

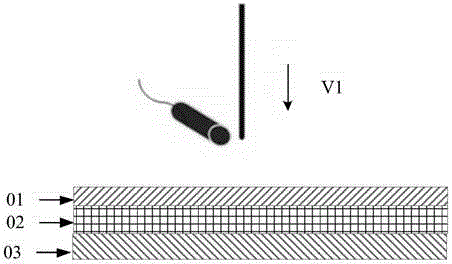

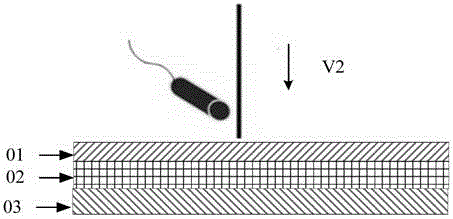

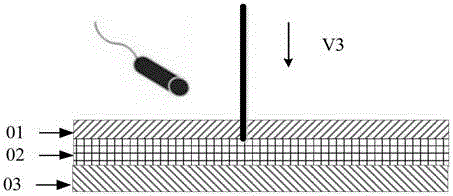

[0051] Embodiment 1 of the present invention provides a method for measuring film thickness, and the steps are as follows: figure 1 As shown, it specifically includes the following steps:

[0052] Step S1, determining the boundary of the film layer according to the difference of the reaction force on the probe.

[0053] Step S2, calculating the thickness of the film layer according to the position data measured by the displacement sensor on the probe or according to the time and movement speed of the probe penetrating the film layer.

[0054] The above method divides different film layers by feeling the change of reaction force when the probe passes through the film layer, and then obtains the thickness of the film layer according to the sensing of the displacement of the probe, or according to the movement speed of the probe penetrating the film layer and The required time is calculated to obtain the film thickness. Through this method, the thickness of the film layer on th...

Embodiment 2

[0076] In order to solve the above-mentioned technical problems, Embodiment 2 of the present invention also provides a device based on the above-mentioned method for measuring film thickness. The schematic diagram of the composition is as follows figure 2 As shown, it specifically includes a probe 10 and a control host 20, the probe is used to move along the film thickness direction, the probe 10 is also provided with a reaction force sensor 11 and a displacement sensor 12, wherein the reaction force sensor 11 is arranged on the probe 10 The top is used to sense the reaction force on the surface of the film layer to the probe, and a mutation signal is generated when the reaction force changes suddenly;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com