A vehicle sound power testing system and testing method

A test system and test method technology, applied in vehicle testing, machine/structural component testing, measuring devices, etc., can solve the problem that it is difficult to meet the operating conditions and load levels of automobiles, and it is difficult to compare competing vehicles and benchmark vehicles horizontally. Implementation and other issues, to achieve the effect of simple and easy-to-use test methods and data processing methods, and convenient layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to have a deeper understanding of the present invention, a specific embodiment is listed below, and the present invention is further described in detail in conjunction with the accompanying drawings.

[0033] This embodiment is a sound power testing system and method for different parts around the engine of the vehicle under the actual vehicle state.

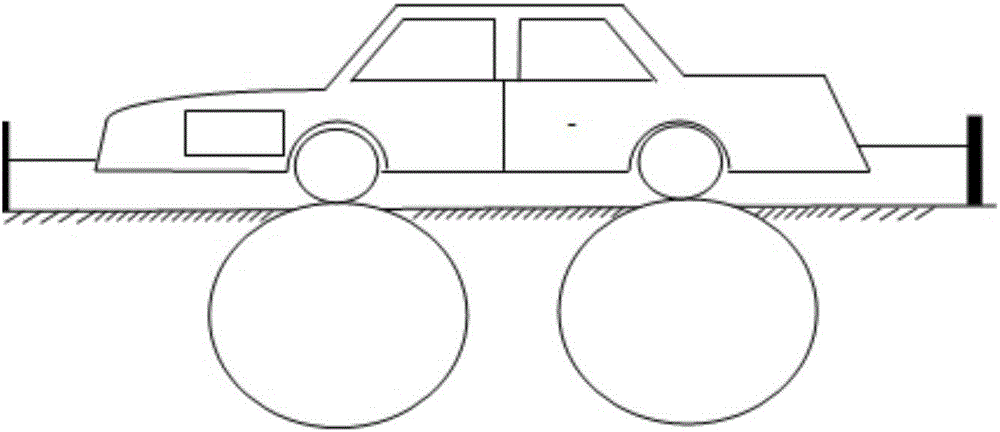

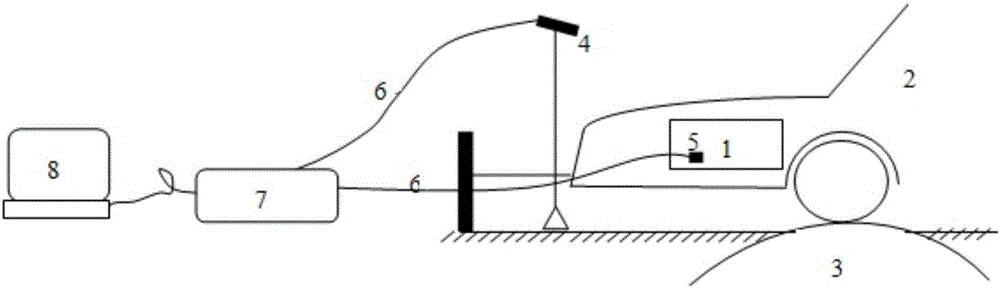

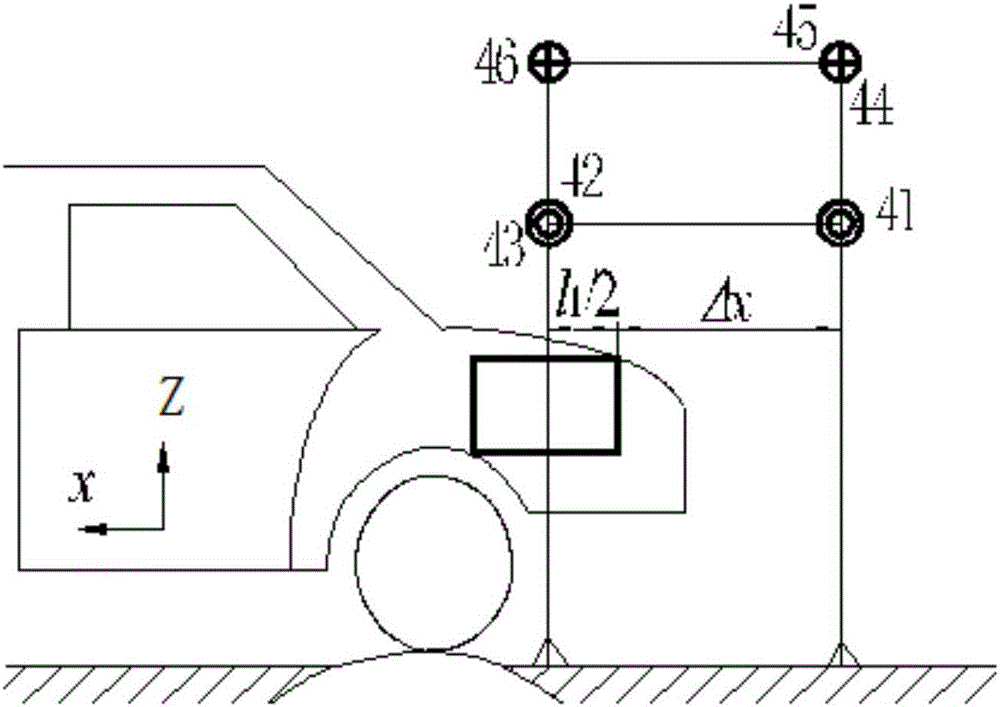

[0034] Such as figure 1 with figure 2 As shown, the test system includes: 4 (6 noise sensors, arranged as Figure 3-Figure 5 shown), pulse signal sensor 5, signal acquisition equipment and fixed bracket, noise sensor 4 is installed on the fixed bracket, and the fixed bracket is placed at the position to be measured of vehicle sound power, pulse signal sensor 5 is installed at the position of the crankshaft pulley of the vehicle, and the noise sensor 4 and the pulse signal sensor 5 are both connected to the signal acquisition device 7 through the wiring harness 6 .

[0035] A test method utilizing the above-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com