Capacitor capacity anomaly detection method

An anomaly detection and capacitor technology, which is applied in instruments, electrical digital data processing, calculation, etc., can solve the problems of cumbersome disassembly of circuit components, laborious and time-consuming on-site operations, etc., and achieve a simple and convenient electromagnetic field test, which is not easy to be shielded and has a broad prospect of practical application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1. Three-phase power electronic capacitors are installed in the power supply system of a certain locomotive and installed on the secondary side of the three-phase transformer. It is stipulated that maintenance should be carried out every certain kilometers or years of operation. According to the requirements of safe operation, in the existing traditional maintenance method, the vehicle bottom cover, equipment box cover and other mounting parts are allowed to be opened after the rolling stock is powered off for more than 30 minutes, and the terminals of the capacitor are removed in a cramped space After the wiring is disassembled, the capacity test is carried out, and the rolling stock is not allowed to be powered on during this process. After testing, resume all disassembly and do torque checks etc. The entire process of the existing traditional maintenance method takes several hours.

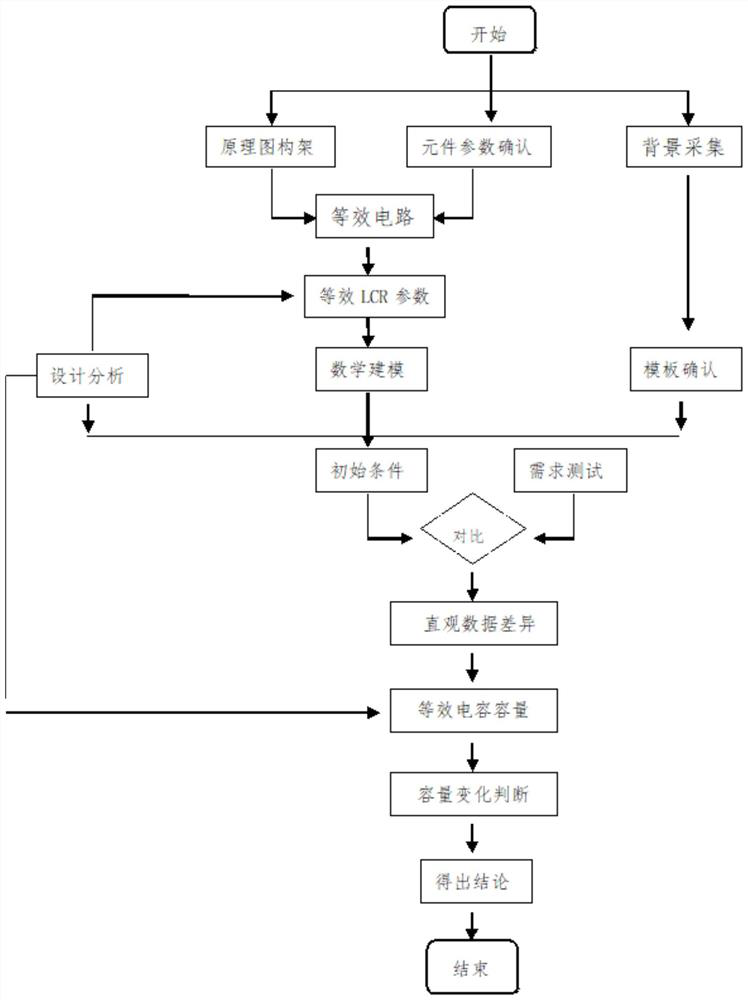

[0043] The abnormal detection method of capacitor capacity described in thi...

Embodiment 2

[0079] In embodiment 2, a DC link supporting capacitor is taken as an example for testing. This capacitor is installed in a high-voltage DC circuit with a rated capacity of 4000uF and is used to stabilize the voltage of this DC circuit.

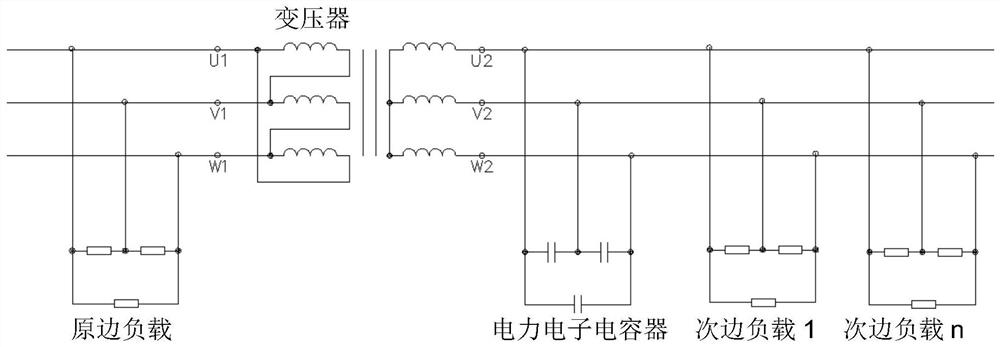

[0080] according to figure 1 In the initial design stage of the project, for the installation circuit and related schematic diagrams of power electronic capacitors, confirm the types of components and related parameters that can cause changes in the power supply at the terminals of the power electronic capacitors, and discard irrelevant circuit branches and components. Figure 7 A simple schematic diagram of the main circuit where the DC link supporting capacitor is shown in this embodiment.

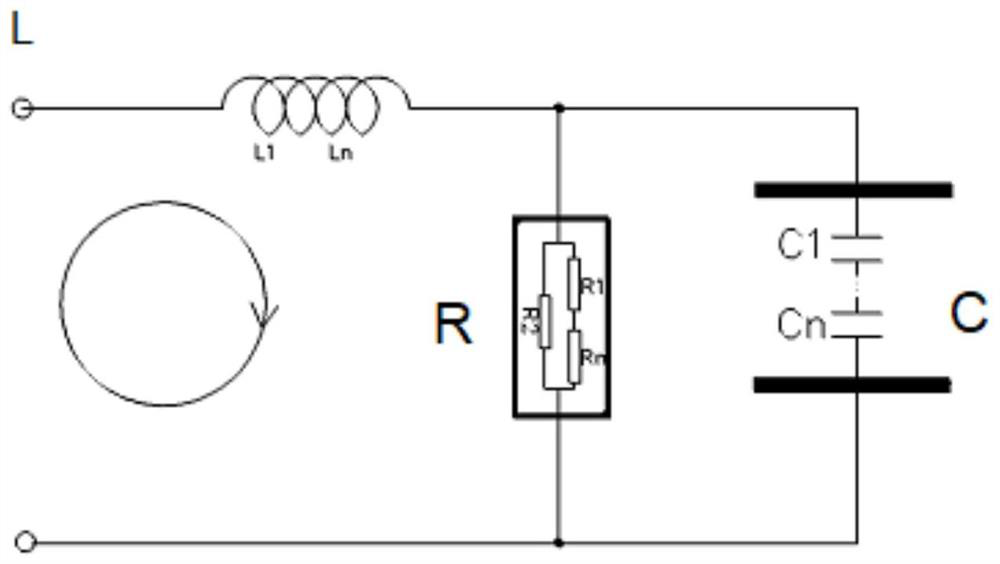

[0081] according to Figure 7 Schematic diagram, carry out schematic diagram structure analysis. It can be confirmed that the transformer isolates the primary and secondary circuits, the measured "capacitor Cd" is only related to the secondary branc...

Embodiment 3

[0093] The main difference between Embodiment 3 and Embodiments 1 and 2 above lies in the background collection link.

[0094] The background acquisition link is the early stage of the template confirmation. The physical test method is used to obtain the relevant data of the samples with normal capacitance and capacity decay under normal conditions through special test equipment. This kind of data will be used as a benchmark value, together with the relevant technical requirements for ensuring the consistency of repeated tests, such as the test method and test requirements when obtaining this value, to form a standardized template file of the benchmark nature, which will be used for data differences of the same test in different periods sex comparison. In this link, data with abnormal capacity decay will also be tested. The device for testing the electromagnetic field may be an electromagnetic radiation analyzer.

[0095] The collection link as described in Example 1 should ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com