Piezoelectric driving type software displacement driver

A piezoelectric drive and driver technology, which is applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve problems such as the difficulty of miniaturizing power components and limiting the application of software drivers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

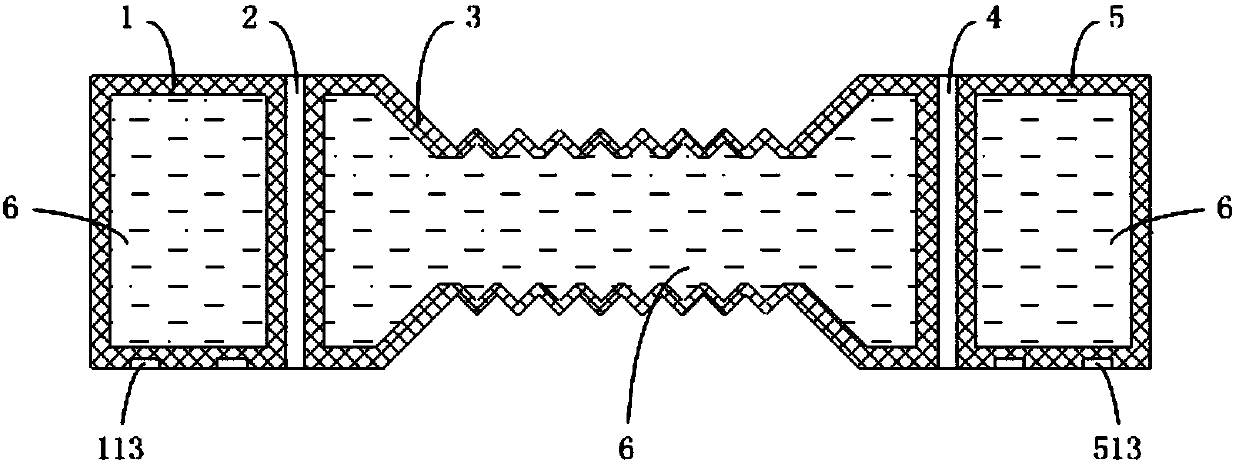

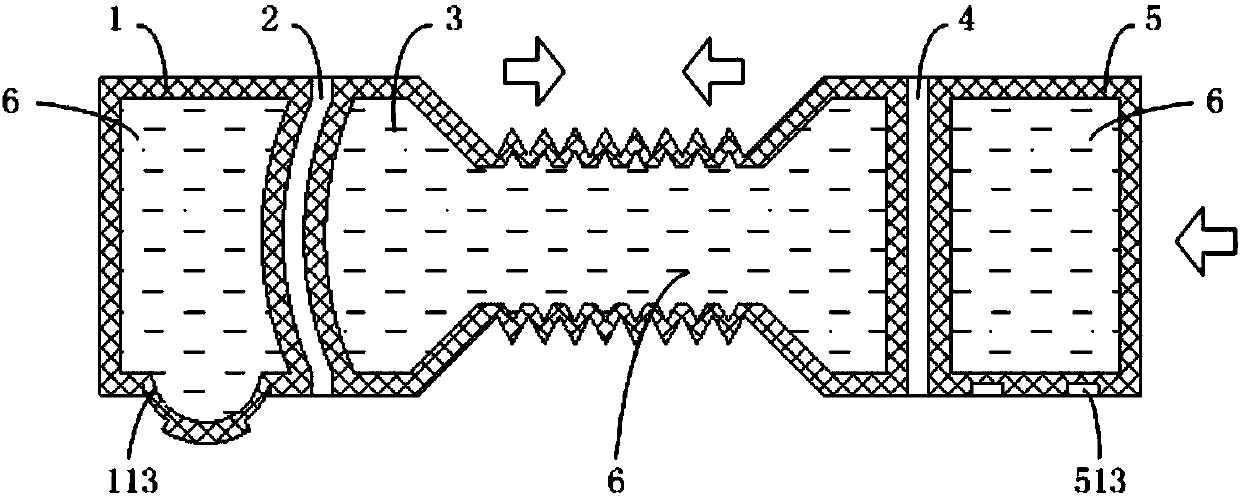

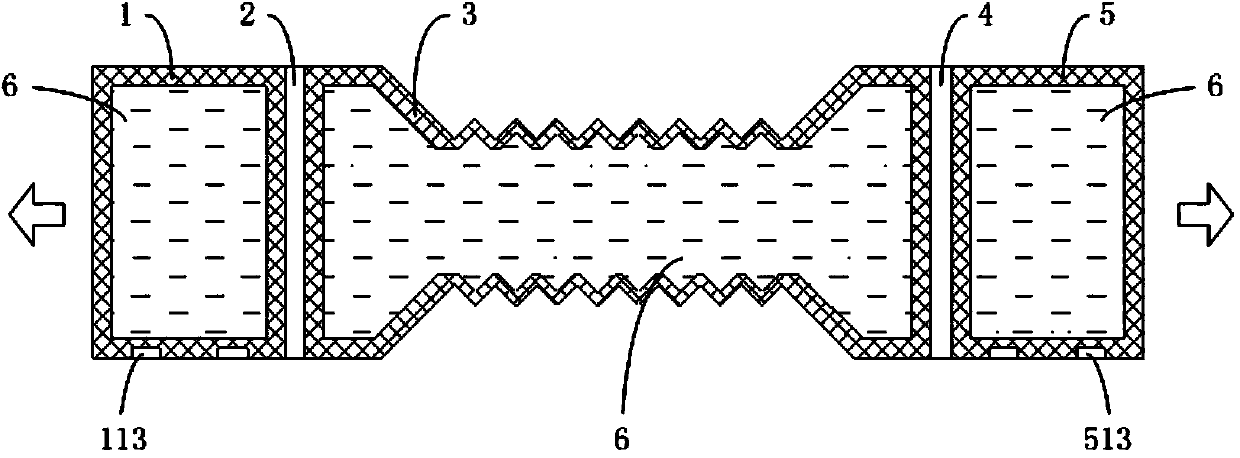

[0017] refer to figure 2 , the piezoelectric driven software displacement driver of the present invention is composed of a first displacement structure 1, a first piezoelectric vibrator 2, a telescopic structure 3, a second piezoelectric vibrator 4, a second displacement structure 5 and a liquid 6, wherein:

[0018] The first positioning structure 1 is a cylindrical structure, which is composed of a soft diaphragm 11 and an internal liquid 6. The soft diaphragm is made of rubber material, and the soft diaphragm 11 on the side of the main body is arranged with a first The upper level flow hole 111 and the second upper level flow hole 112, the liquid 6 is injected through the second upper level flow hole 112, the internal gas is discharged from the first upper level flow hole 111, and the inside is filled with the liquid 6. The first hole 111 and the second hole 112 are sealed with glue, and a thickness reduction area 113 is arranged at the soft diaphragm 11 on the side of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com