Catheter assembly having a protective sheath and method of manufacture

A technology of protective sleeve and catheter, applied in the direction of catheter, connecting pipe, coating, etc., can solve the problem of not using PTA balloon and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Elements or parts of elements common to the embodiments described below will be denoted by the same reference numerals.

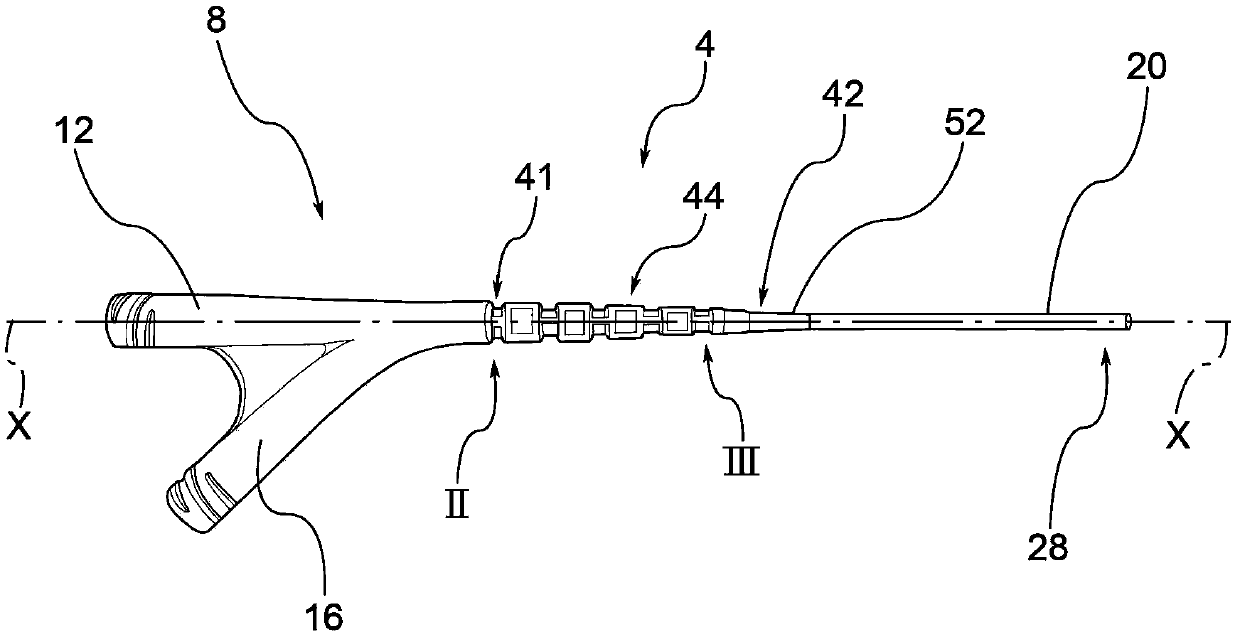

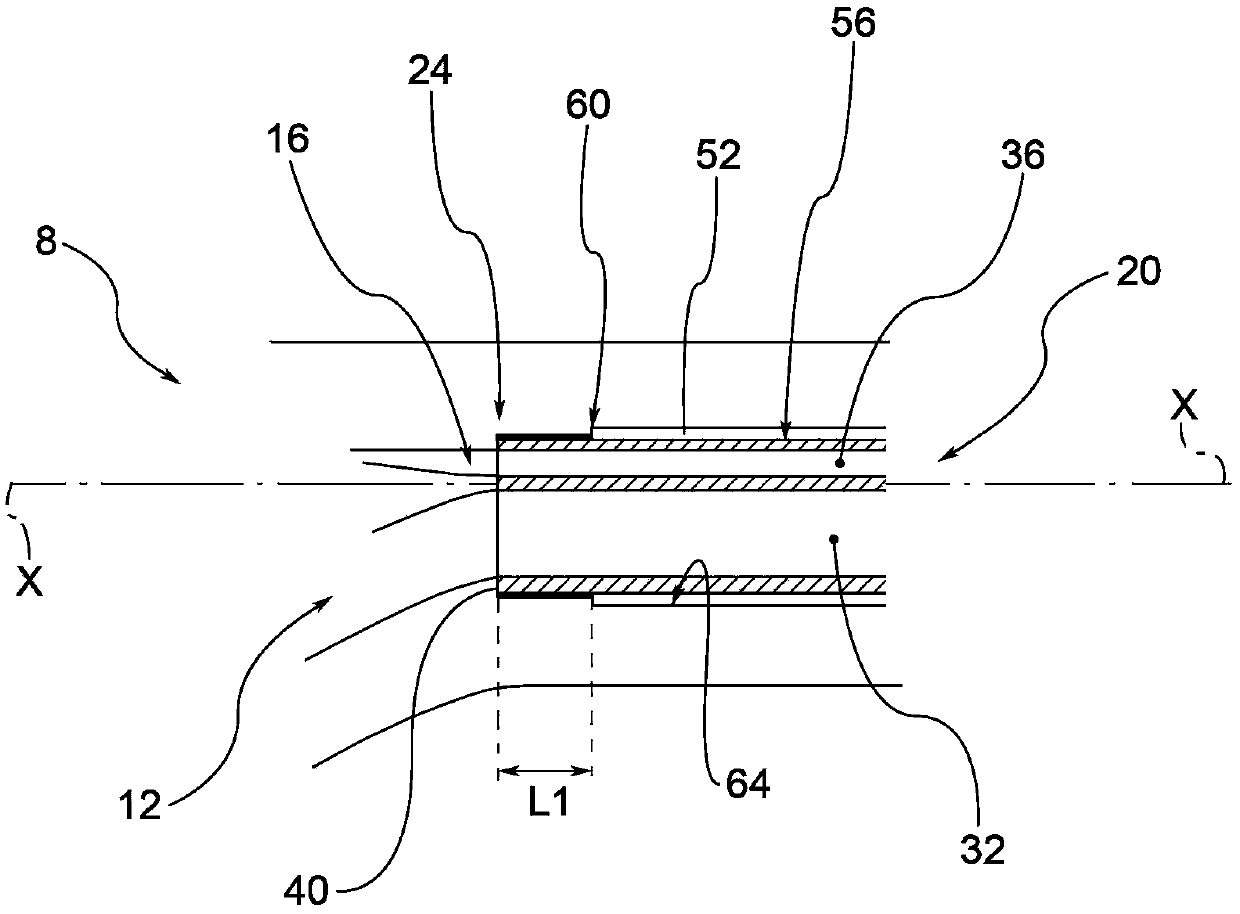

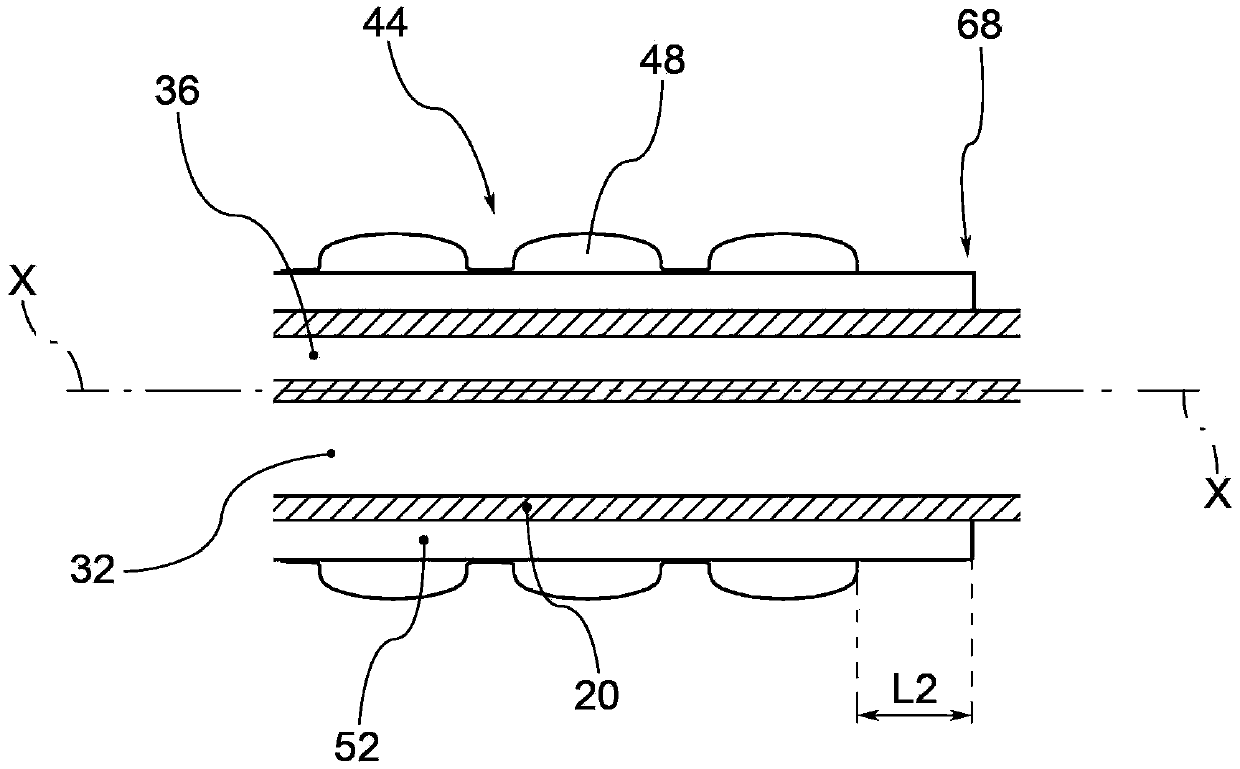

[0018] Referring to the preceding figures, the reference numeral 4 generally denotes a catheter, particularly but not exclusively a catheter for percutaneous transluminal angioplasty (PTA).

[0019] The catheter 4 comprises a connection 8 comprising a wire channel 12 and an inflation channel 16 .

[0020] In general, the catheter 4 according to the invention has a coaxial or double lumen structure. Anyway, the catheter can also have further lumens for different purposes.

[0021] The wire channel 12 is used for housing a wire for guiding and inserting the catheter 4 in a predetermined container. Additionally, an inflation channel 16 is useful in order to deliver pressurized fluid to the distal end of the shaft. For example, the fluid under pressure may be air or fluid. Furthermore, it is possible to use the inflation channel as, for example, a pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com