Edible fungus inoculation device

An inoculation device, edible fungus technology, applied in application, horticulture, botany equipment and methods, etc., can solve the problems of high labor intensity, unsuitable operation, large equipment investment, etc., to improve work efficiency, reduce production costs, and reduce labor the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

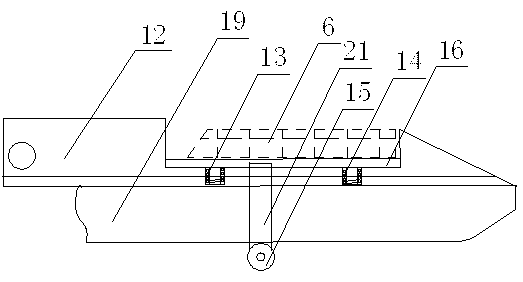

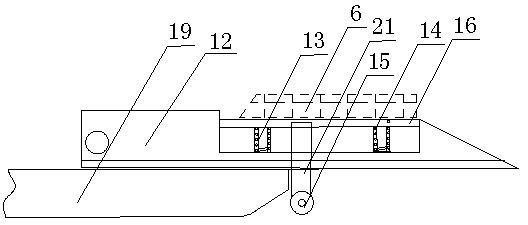

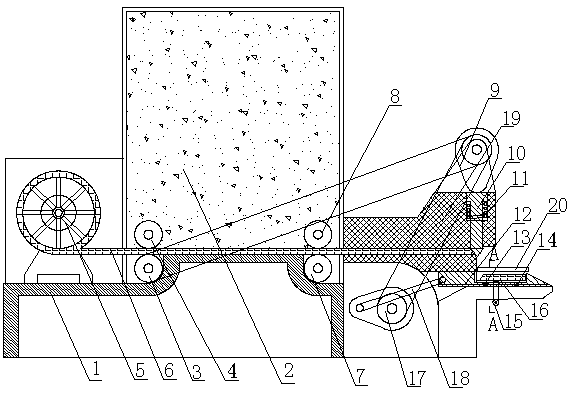

[0020] like figure 1 , Figure 4The edible fungus inoculation device shown includes a base 1, the edible fungus strain storage container 2 is located above the base 1 and is connected to the base 1, and the belt release mechanism 5 is located on the first side of the storage container 2 and is connected to the base 1. Connected, the outside of the belt release mechanism 5 is provided with a closed cover connected to the machine base 1, and an ultraviolet germicidal lamp is arranged in the closed cover, and the lower feeding pulley 3 and the upper feeding pulley 4 are located at the bottom of the storage container 2 near the belt release mechanism 5. On one side, the lower feeding pulley 3 and the upper feeding pulley 4 are rotatably connected with the storage container 2 through bearing seats and bearings, wherein the upper feeding pulley 4 is pressed against the lower feeding pulley 3 by gravity, and its upper and lower positions can be adjusted, and the lower feeding pulley ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com