Device for cultivation and inoculation of edible fungi

A technology for edible fungi and strains, applied in the fields of application, horticulture, and botanical equipment and methods, can solve the problems of high labor intensity, increase infection of miscellaneous bacteria, and inappropriate operation, so as to improve work efficiency, shorten the time for bacteria to grow, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

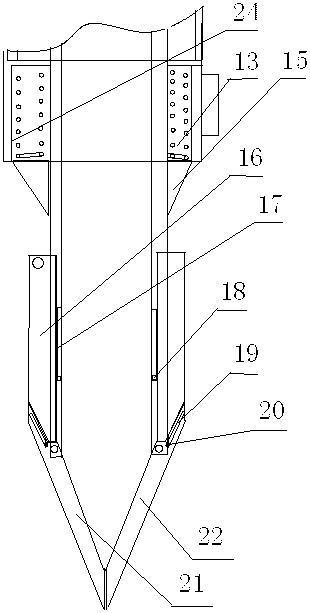

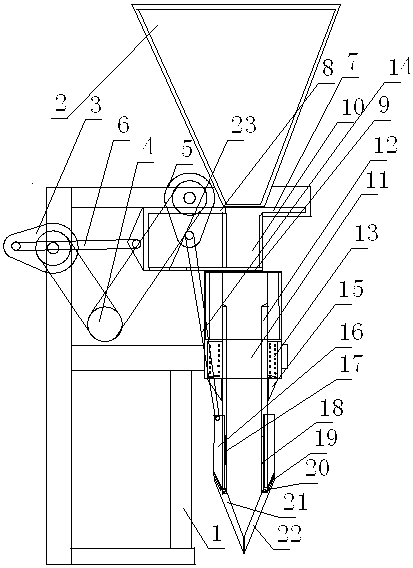

[0023] Such as figure 1The shown device for cultivating and inoculating edible fungi has a base 1; the edible fungus strain storage container 2 is fixedly connected to the top of the base 1, and the cavity 10 is connected to the base 1 with the storage container 2. The bottom discharge port is connected, and the "匚" shaped gate is slidably connected to the base 1. The upper end of the cavity 10 has a cavity 7 for the sliding of the first gate 8. The "匚" shaped The gate plate has a first gate plate 8 slidably connected above the upper port of the cavity 10, a second gate plate 9 slidably connected below the lower port of the cavity 10, and the second gate plate 9 has a through Hole 23, the first cam 3 is connected with the base 1 to push the "匚" shaped gate to slide, and the two ends of the first driven rod 6 are respectively hinged with the first cam 3 and the "匚" shaped gate , the sliding sleeve 11 is connected with the machine base 1 and is located below the cavity 10, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com