Fully-automatic liquid inoculating machine of bag-cultivated edible mushroom bag

An edible fungus, fully automatic technology, applied in cultivation, application, plant cultivation and other directions, can solve the problems of low degree of automation, low production efficiency, inconsistent inoculum amount, etc., and achieve the effect of reasonable structure design and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

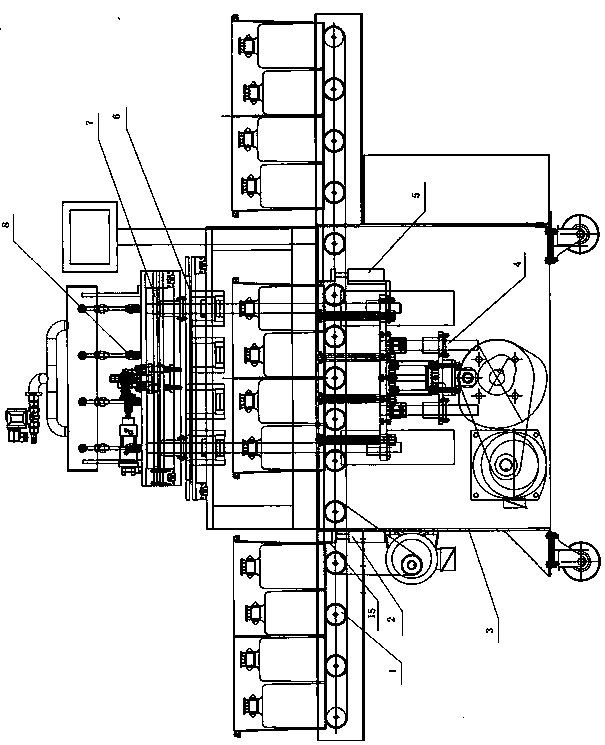

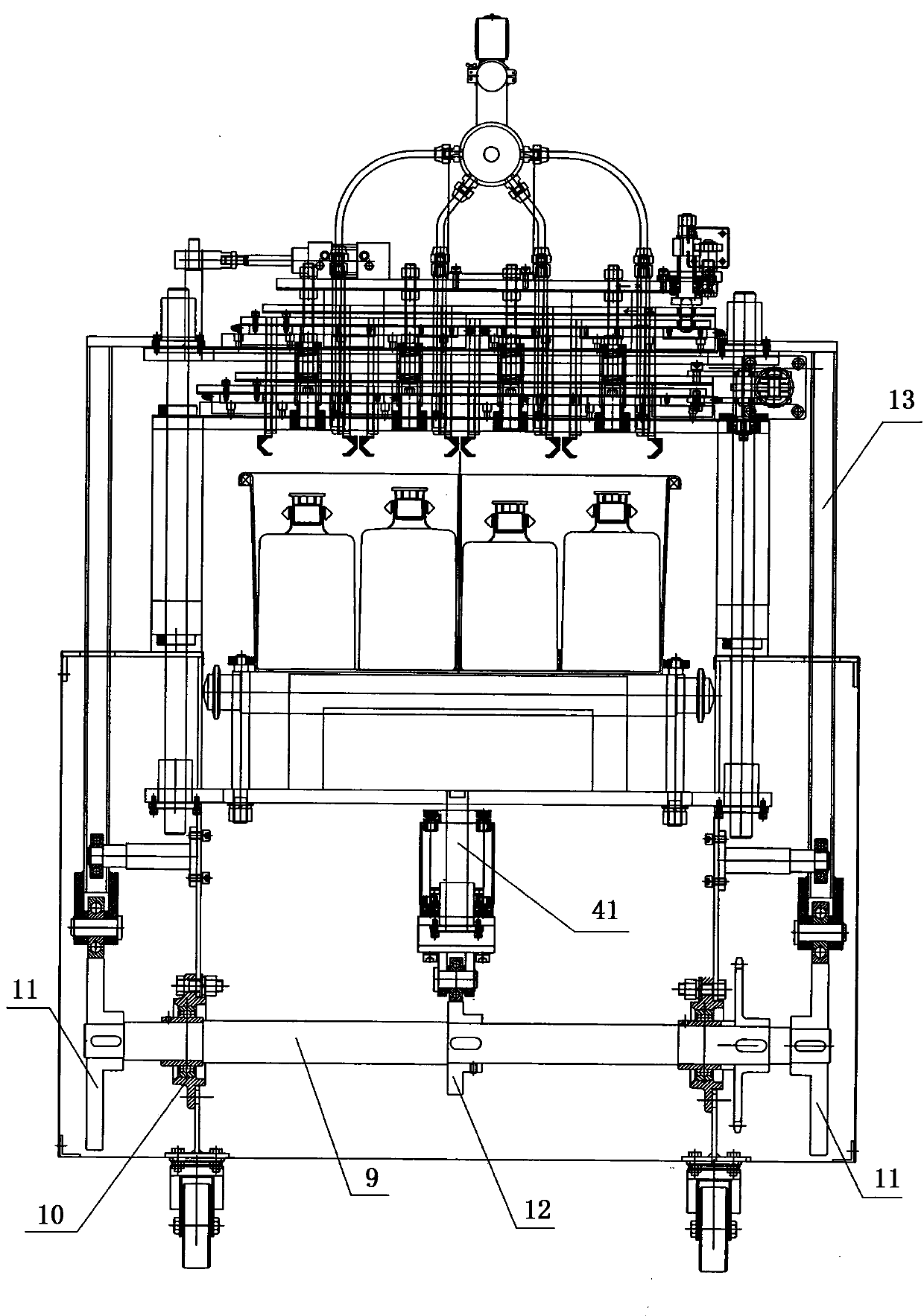

[0048] Embodiment 1, with reference to Figure 1-10 A kind of fully automatic liquid inoculation machine of edible fungus in bag, this inoculation machine comprises frame 3, is provided with conveying device 1, jacking device 4, clamping device 6, lifting cover device 7 and inoculation device on frame 3 device 8;

[0049] A first block 15 connected to the first blocking power device 2 is provided on the frame 3 at the inlet side of the conveying device 1;

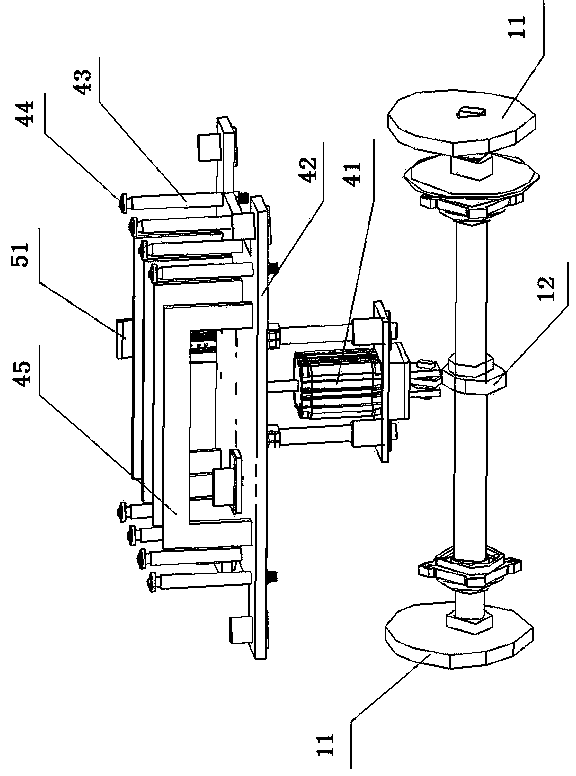

[0050] Described jacking device 4 is located at the below of conveying device 1, and jacking device 4 comprises jacking power unit 41, and the power output end of jacking power unit 41 is fixed with jacking plate 42, is set on jacking plate 42 There are jacking brackets 45 and a second blocking power device 5; several guide rods 14 are installed on the side of the jacking plate 42; the second blocking power device 5 is connected with a second block 51; the jacking device 4 The bottom is connected on the jacking lifting me...

Embodiment 2

[0057] Embodiment 2, in the fully automatic liquid inoculation machine for bag-grown edible fungi described in Embodiment 1: the first blocking power device 2, the second blocking power device 5, the jacking power device 41, the first rubbing power device 66 , the second rubbing power device 78 and the displacement power device 76 are cylinders or power devices composed of motors and transmission thereof.

Embodiment 3

[0058] Embodiment 3, with reference to figure 2 , image 3 ; In the bag-grown edible fungi bag full-automatic liquid inoculation machine described in embodiment 1 or 2: the described jacking lifting mechanism 12 is a jacking cam, and the described lifting mechanism 11 is a lifting cam; The cam is fixed in the middle of the main shaft 9, and the cover lifting cam is arranged on both sides of the main shaft 9. The main shaft 9 is connected with the main motor through the main transmission device 10, and the bottom of the jacking device 4 is supported on the jacking cam; the lower end of the ejector rod 13 Supported on the lid lift cam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com