A zero position device for a double-end grinding machine

A technology of double-end face grinder and zero position device is applied in the field of zero position device, which can solve the problems of many preparations, time-consuming and laborious, and achieve the effect of rapid recovery of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

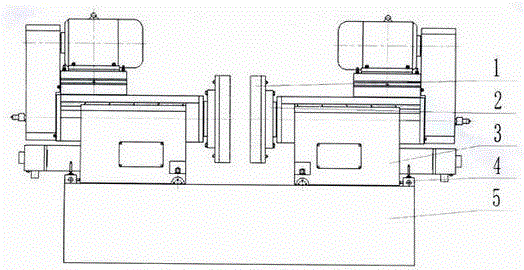

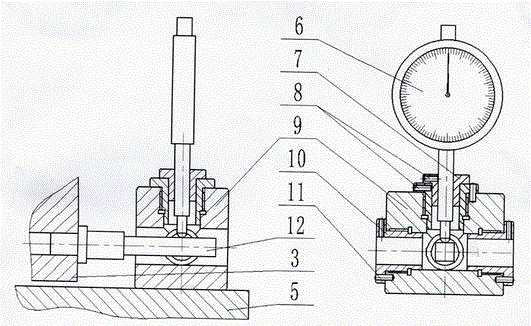

[0011] In this technical solution, during the debugging process of the machine tool, the adjustment of the left and right angles does not need to dismantle the grinding wheel, the dressing arm, etc., and does not need to install special tooling. It only needs to be read by the dial indicator when moving the grinding head base. The specific value can realize accurate measurement, and when the accuracy of the left and right spindle ends of the machine tool is parallel or perpendicular to the dresser, the accuracy can be quickly restored by using this device, see figure 1 As shown, the left and right grinding heads are respectively fixed on the grinding head base, and the base is assembled with the bed 5. The left and right grinding heads are respectively equipped with the grinding wheel main shaft 2, and the main shaft 2 is equipped with the grinding wheel 1. The left and right grinding Both sides of the head are respectively equipped with zero device 4, see figure 2 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com