Steel bar binding and corrugated pipe locating device for precasting box girder

A technology of steel bar binding and positioning device, applied in manufacturing tools, ceramic molding machines, etc., can solve the problems of inaccurate coordinates of bellows pipes and spatial position interference, and achieve the effect of overcoming spatial position interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

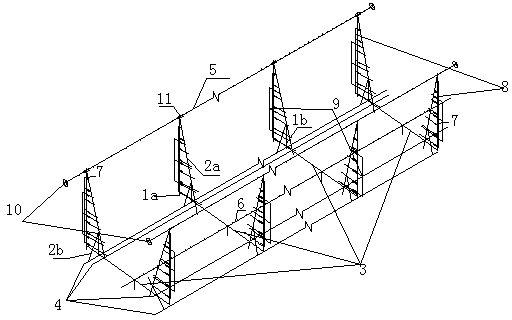

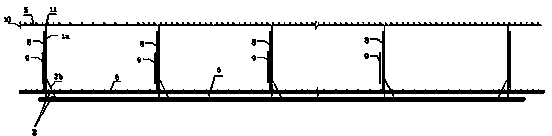

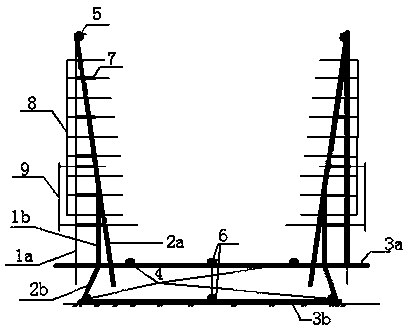

[0020] Such as Figure 1 to Figure 6 As shown, a prefabricated box girder reinforcement binding and bellows positioning device adopts an inverted trapezoidal positioning structure unit, which includes a first vertical reinforcement 1a, a second vertical reinforcement 1b, a first oblique reinforcement 2a, a second oblique Steel bar 2b, the first horizontal connecting steel bar 3a, the second horizontal connecting steel bar 3b and the longitudinal steel bar 4 are respectively connected and supported to form a box girder reinforcement skeleton, the top stirrup positioning bar 5, the bottom stirrup positioning bar 6, the horizontal sleeve 7, and the horizontal steel The positioning pin device 8 and the bellows positioning pin device 9 form a box girder steel bar limiting device, and form a box girder prefabricated steel bar positioning and bellows positioning device model as a whole.

[0021] Vertical reinforcement 1a, vertical reinforcement 1b, oblique reinforcement 2a, oblique r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com