Cable pay-off specialized vehicle

A technology for automobiles and cables, applied in the field of special-purpose vehicles for cable pay-off, can solve the problems of high cost, restrict the development of electric power industry, low construction efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

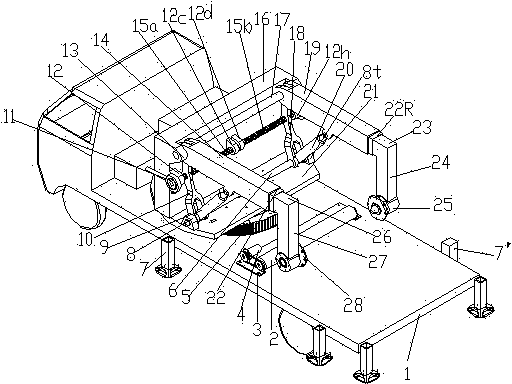

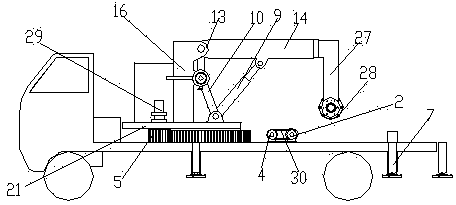

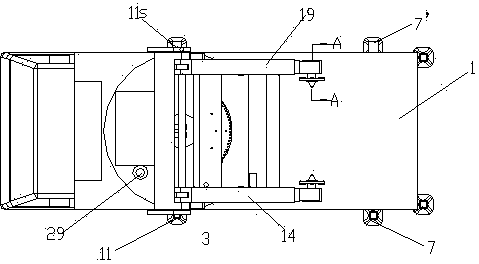

[0022] given in the present invention figure 1 , figure 2 , image 3 In the embodiment shown in ,, three supporting legs 7 are respectively arranged on the left and right sides below the automobile chassis 1, and the first supporting leg hydraulic cylinders 65, 65, The second outrigger hydraulic cylinder 70 and the third outrigger hydraulic cylinder 73 ; the first telescopic hydraulic cylinder 40 , the second telescopic hydraulic cylinder 41 , and the third telescopic hydraulic cylinder 42 .

[0023] The supporting hydraulic cylinder is used to support the cargo pressure on the automobile chassis 1, and the extension hydraulic cylinder is used to extend and return the supporting legs of the automobile chassis 1.

[0024] The car chassis 1 is provided with a gear seat, and the first gear 5 (big gear) and the disc seat 21 are installed on the gear seat on the car chassis. On the circular hole on the disc seat 21, the second gear (pinion) installed on the shaft of the first h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com