Pressing-pushing type box body and manufacturing process

A box body and box cover technology is applied in the field of push-push box bodies and manufacturing processes, which can solve the problems of easily damaged electronic locks, inability to withstand pressure, and box inability to fall, and achieve high safety performance, simple structure, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with accompanying drawing:

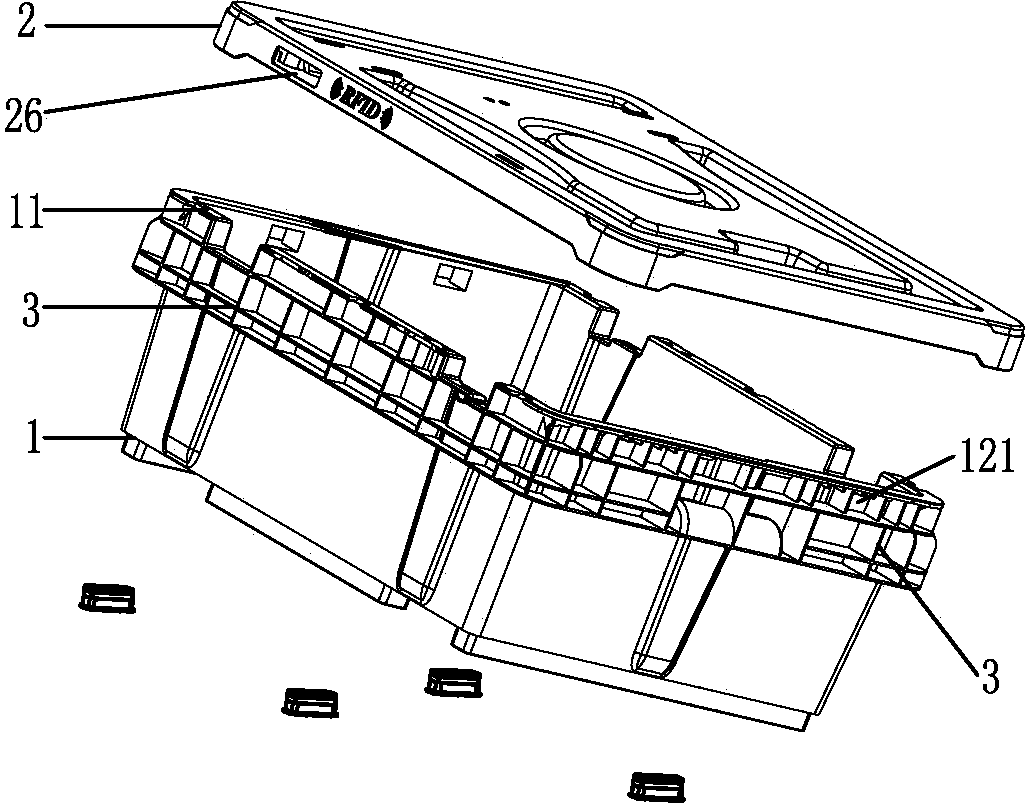

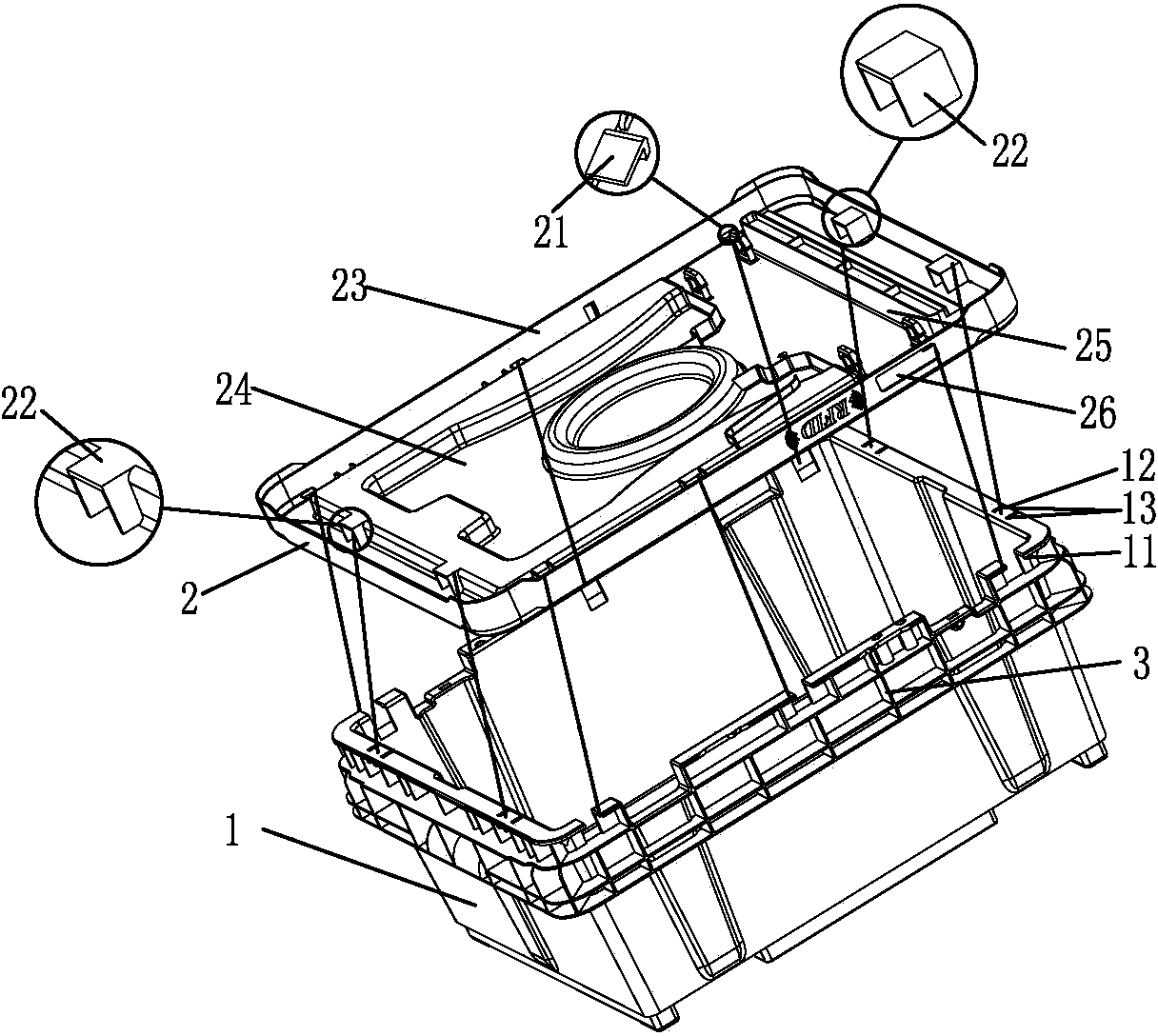

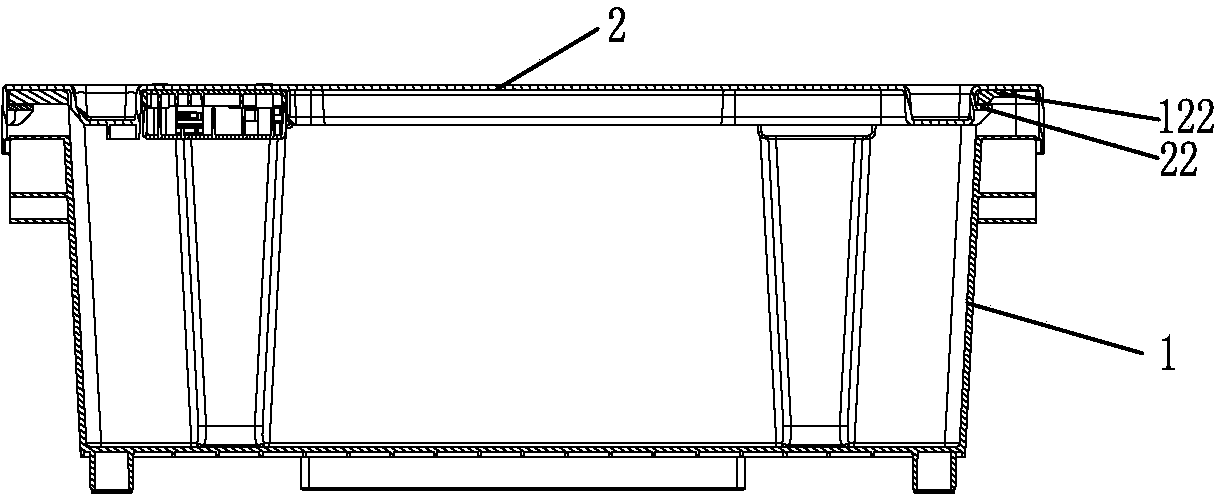

[0027] see Figure 1 to Figure 6 As shown, the push-and-push box includes a box body 1 and a box cover 2, and the two side walls of the long side opposite to the mouth end of the box body 1 are respectively recessed to form two L-shaped walls combined with a number of side walls and a top wall. The side slot 11 of the side slot 11 is provided with several L-shaped ribs 21 protruding from the inner plane of the box cover 2 corresponding to the side slot 11; There is a through groove 13, the bottom end of the through groove 13 forms a frame groove 122, and the top wall 12 corresponding to the through groove 13 is vertically bent to accommodate the tongue piece 121 in the frame groove 122, and the inner plane of the box cover 2 at the corresponding position A frame-shaped tongue 22 is protruded; when the box cover 2 is fastened to the box body 1, the L-shaped bone i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com