Cloth strip sewing auxiliary device

An auxiliary device and sewing technology, applied in sewing equipment, sewing machine components, cloth feeding mechanisms, etc., can solve the problems of unstable sewing cloth strips, poor product quality at the production place, and high probability of rework, etc. The effect of high production efficiency and high sewing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

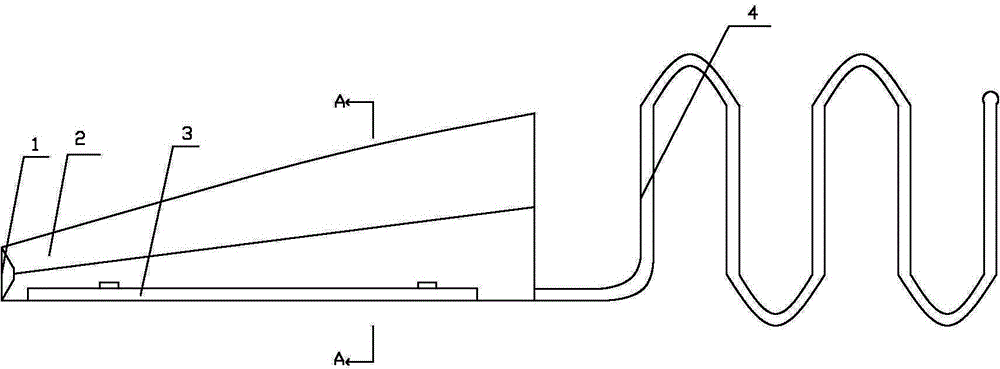

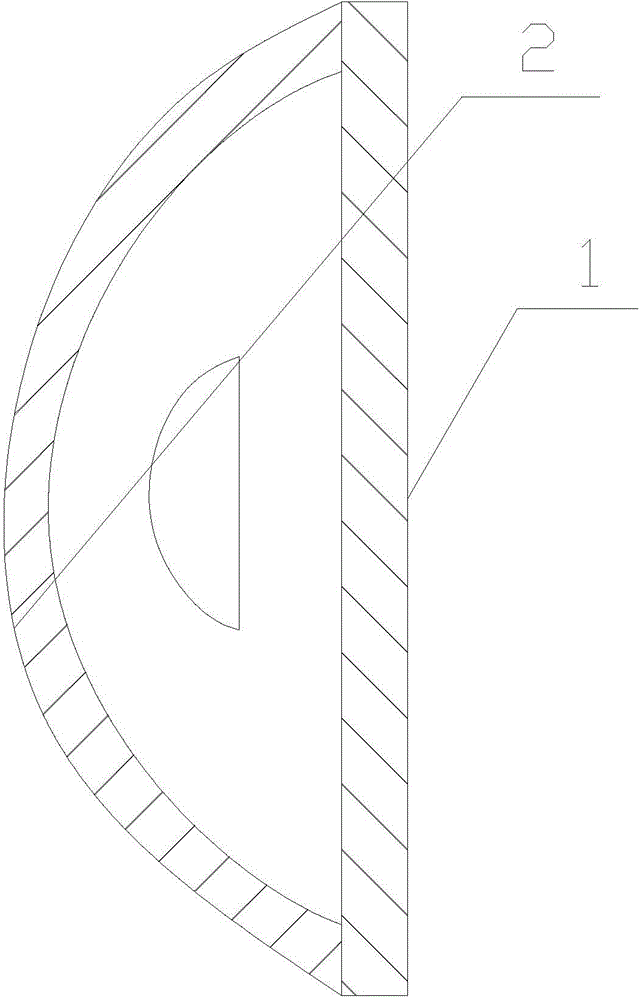

[0012] like figure 1 , figure 2 As shown, a cloth strip sewing auxiliary device includes a hollow tube body composed of a metal straight plate 1 and a metal arc plate 2, the hollow tube body is arranged on a mounting plate 3, and the hollow tube body is that one nozzle is smaller than the other. The tapered tube with a large nozzle, through the hollow tube with a tapered cross section, effectively guides the sewing point of the cloth tape, with high sewing precision and more rationalization. An S-shaped positioning bar 4 is set at the larger nozzle to facilitate The cloth belt is straightened, and the efficiency is higher. The corners of the metal straight plate 1 and the metal curved plate 2 are polished smoothly to avoid roughness and improv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com