Ultrasonic wave paper thickness measuring device

A thickness measurement, ultrasonic technology, applied in the direction of measuring devices, using ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems affecting the work of the thickness measuring device, can not emit ultrasonic waves, and the bubbles are not easy to remove, etc., to achieve simple disassembly and assembly, The effect of low production cost and improved precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

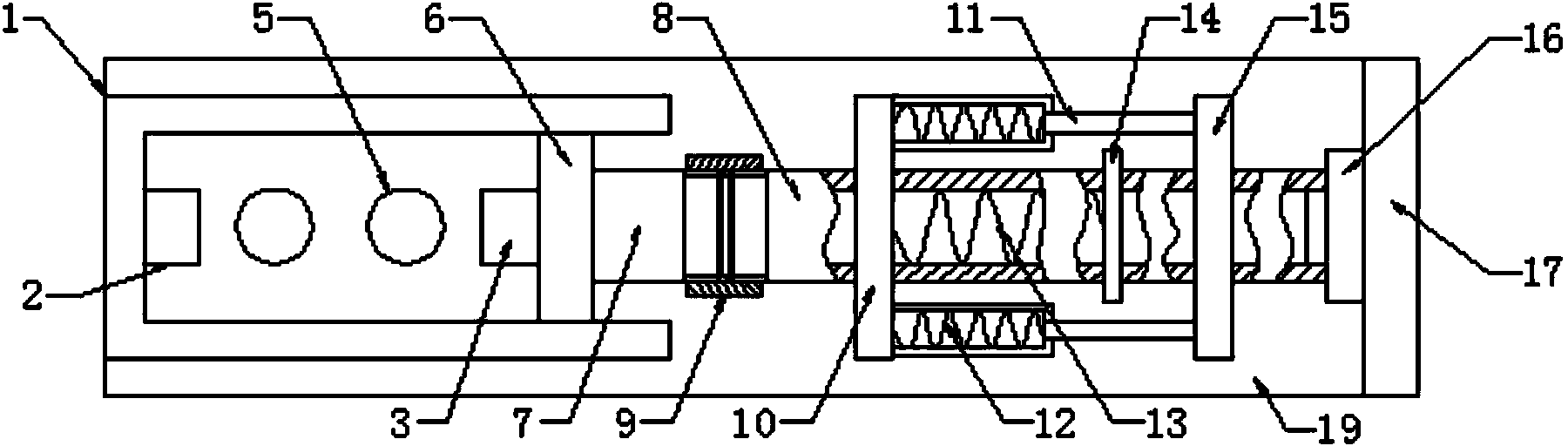

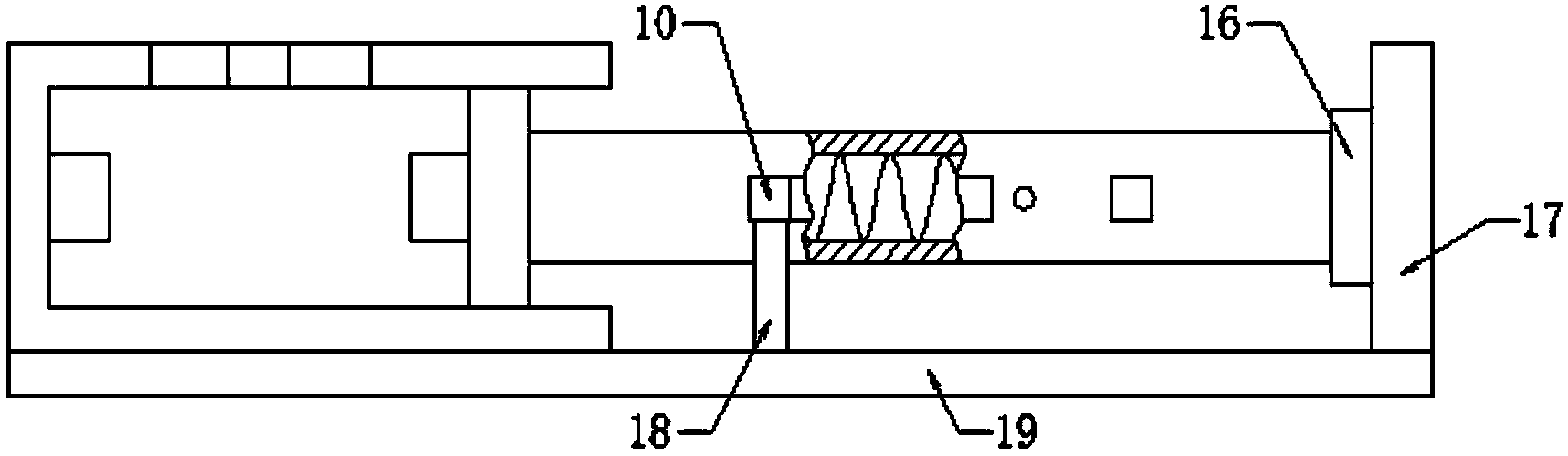

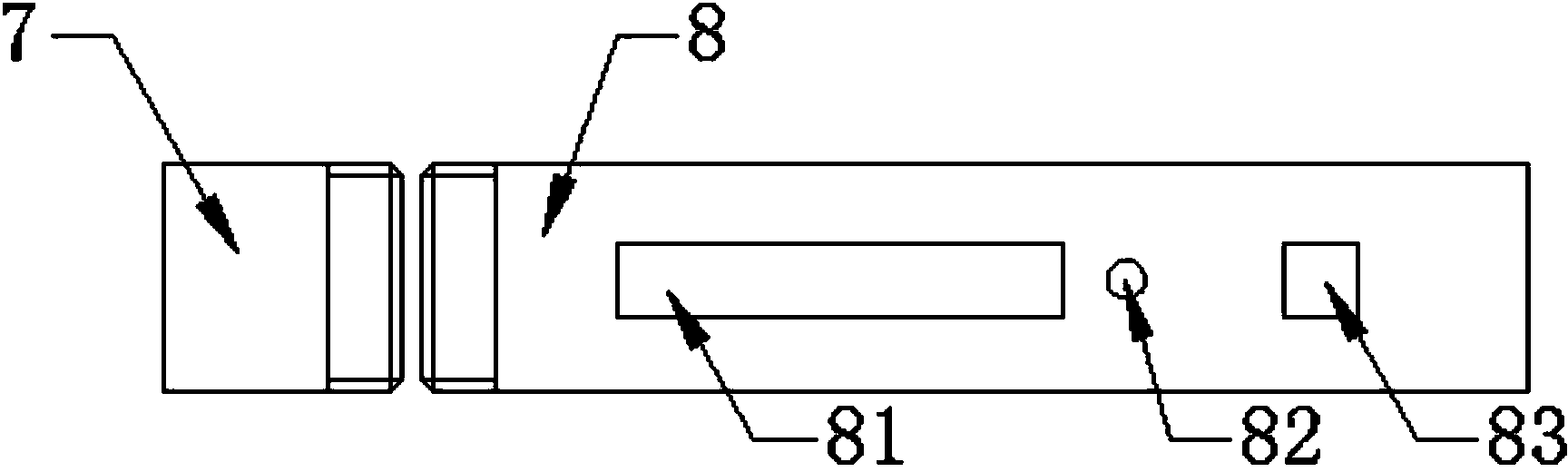

[0022] The method of the present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0023] The ultrasonic paper thickness measuring device designed by the present invention (referred to as the thickness measuring device) includes a tank body 1, a left ultrasonic probe 2, a right ultrasonic probe 3, a ventilation tube 5, a piston 6, a left cylindrical tube 7, a right cylindrical tube 8, and a casing 9 , Fixed pin 10, upper electromagnet 11, lower electromagnet 12, spring 13, locking pin 14, connecting pin 15, measuring end face 16, bearing paper surface 17, bracket 18, base plate 19.

[0024] The left ultrasonic probe 2 is connected with the bottom of the tank body 1 . The right ultrasonic probe 3 is connected with the left end of the piston 6 and faces the left ultrasonic probe 2 . The tank body 1 has liquid inside. There is a ventilation hole on the tank body, and the ventilation pipe 5 links to each other with the ven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com