Mouthpiece anti-loose device and anti-loose method

A horn mouth and anti-loosening technology, applied in the direction of electrical components, etc., can solve the problems of loosening the horn mouth, no anti-loosening protection of the horn mouth, explosion of electrical equipment, etc. The effect of lock failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

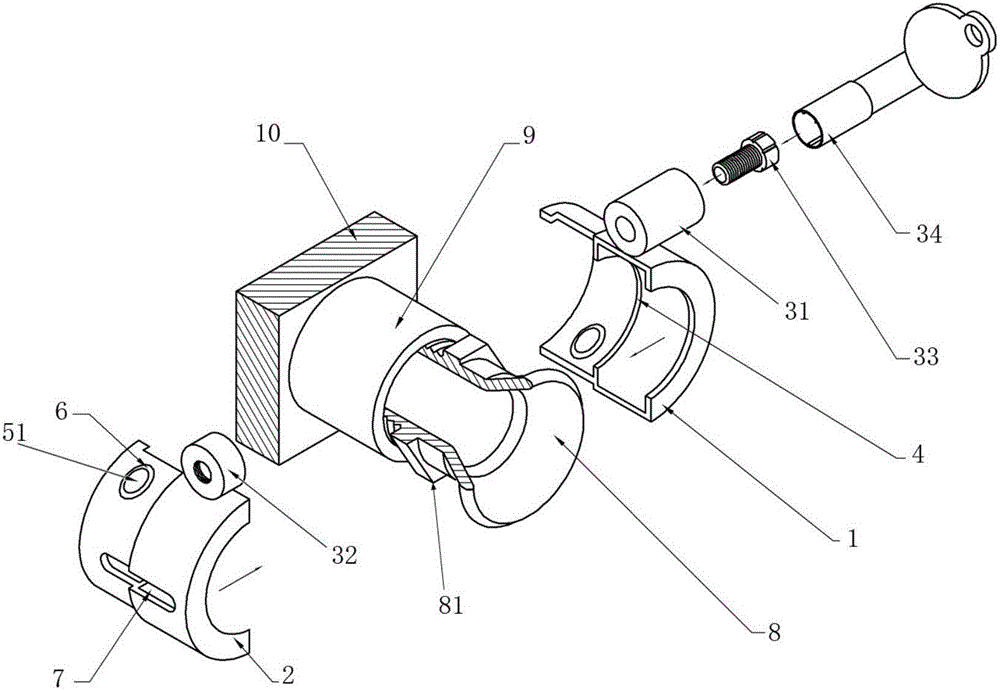

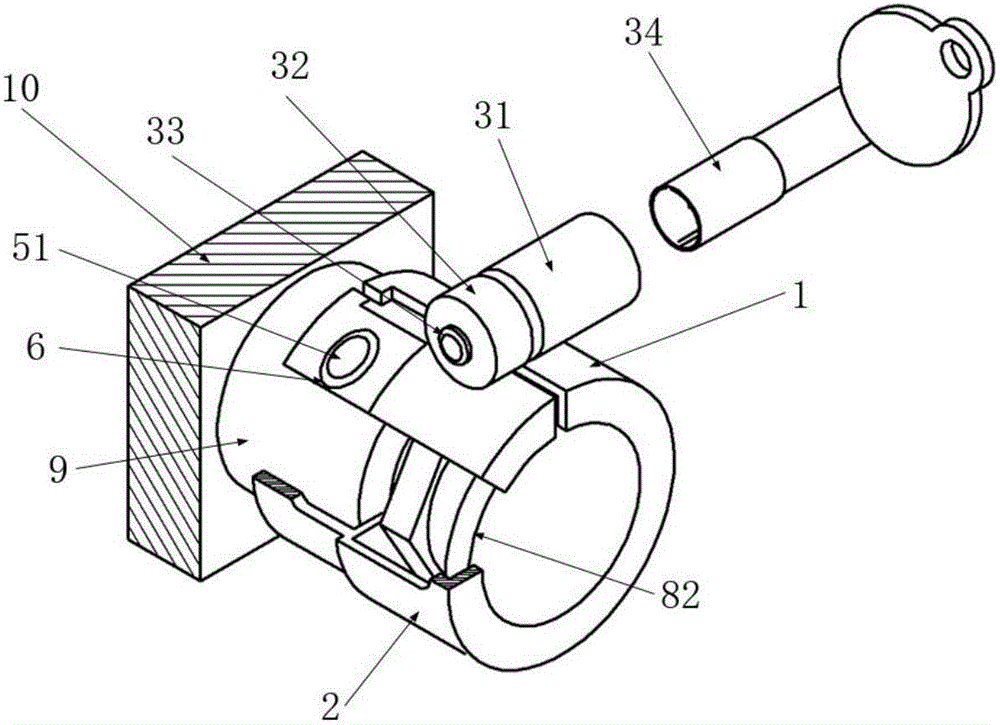

Method used

Image

Examples

Embodiment 1

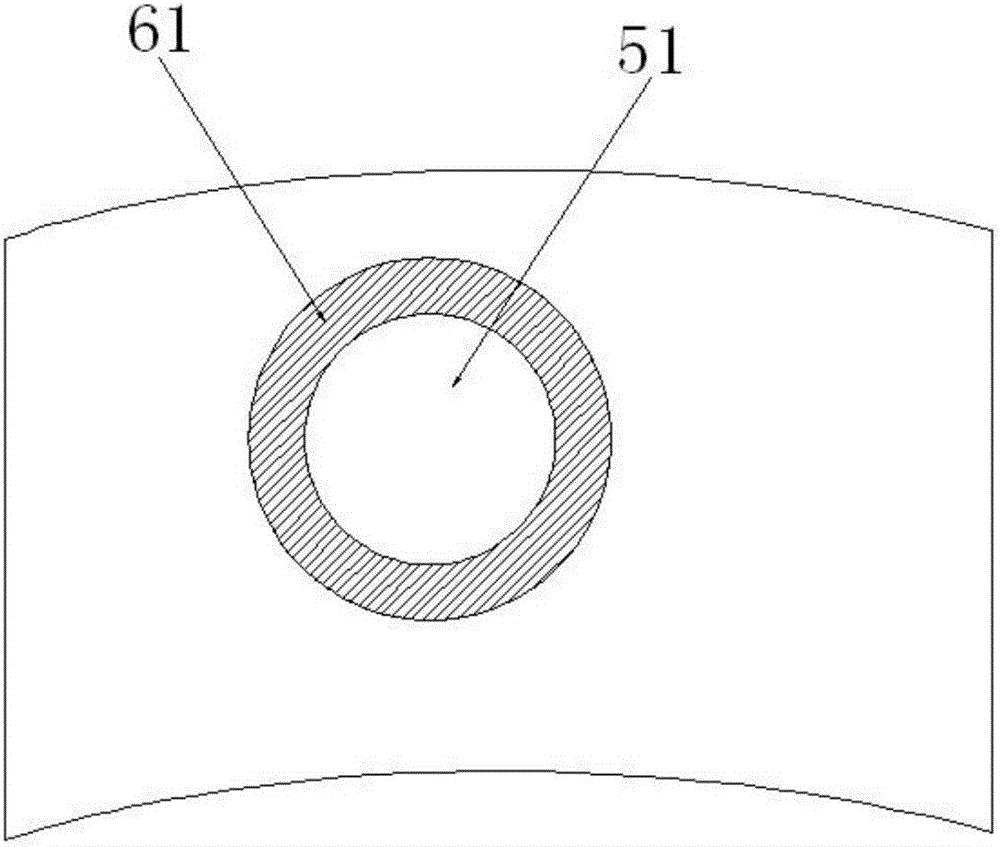

[0031] As shown in FIG. 3 , a through hole 51 is opened on the inner wall connecting the first lock body 1 and the second lock body 2 with the joint 9 , and then the prepared anti-loosening pad 6 is installed in the through hole 51 . In this case, it is preferable to set the anti-loosening pad 6 as a washer 61 that matches the through hole 51, and the outer wall of the washer 61 is provided with a groove, which can be connected with the first lock body 1 and the second lock body around the through hole 51. The two lock bodies 2 are engaged and sealed.

[0032]In this embodiment, there are many options for the shape of the groove, such as U-shape, semi-U-shape, trapezoid, etc., all of which can perform the same function.

Embodiment 2

[0034] As shown in FIG. 4 , a blind hole 52 is opened on the inner wall connecting the first lock body 1 and the second lock body 2 with the joint 9 , and then the prepared anti-loosening pad 6 is installed in the blind hole 52 . In this case, the anti-loosening pad 6 can be configured as a spacer 62 matching the blind hole 52 , which has a protrusion protruding relative to the inner wall surfaces of the first lock body 1 and the second lock body 2 . There are many options for the shape of the protruding part, such as a column that is integrated with the spacer 62 , or a sheet that fits and extends around the inner walls of the first lock body 1 and the second lock body 2 .

[0035] The anti-loosening pad 6 of the present invention can be made of various materials, preferably made of one or more of rubber, nylon or other anti-friction materials, which can avoid the trouble of using (pasting) friction materials such as rubber in the traditional technology. The disadvantage of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com