Patents

Literature

67results about How to "Huge market application potential" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

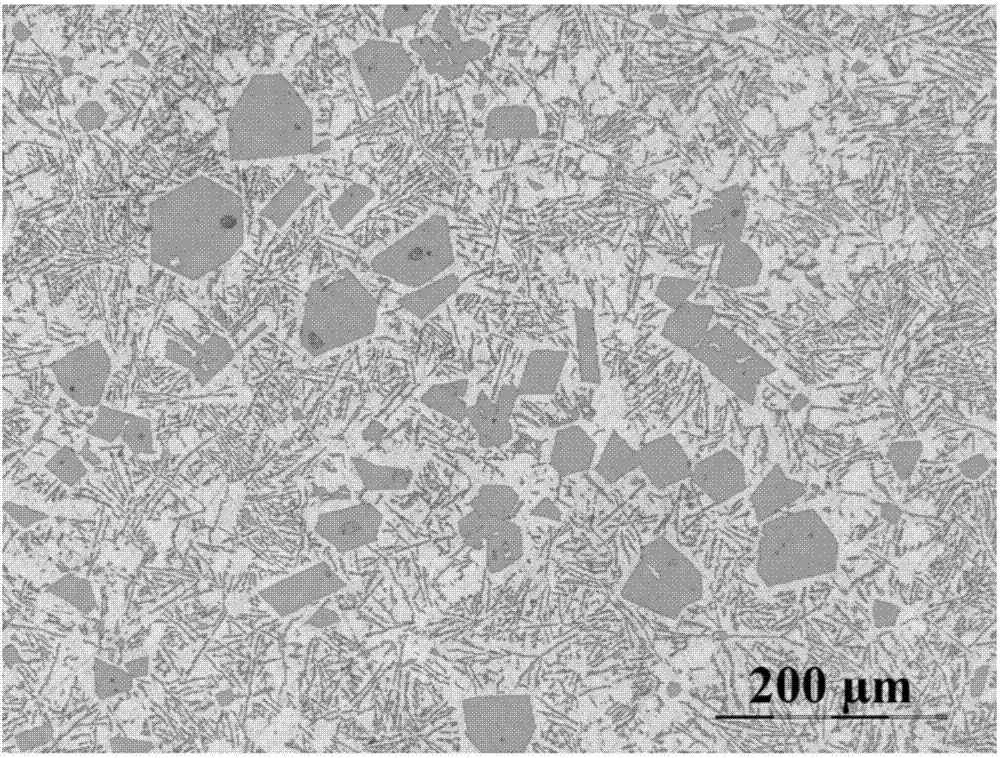

Lamellar double-phase high-strength and high-toughness steel and preparation method thereof

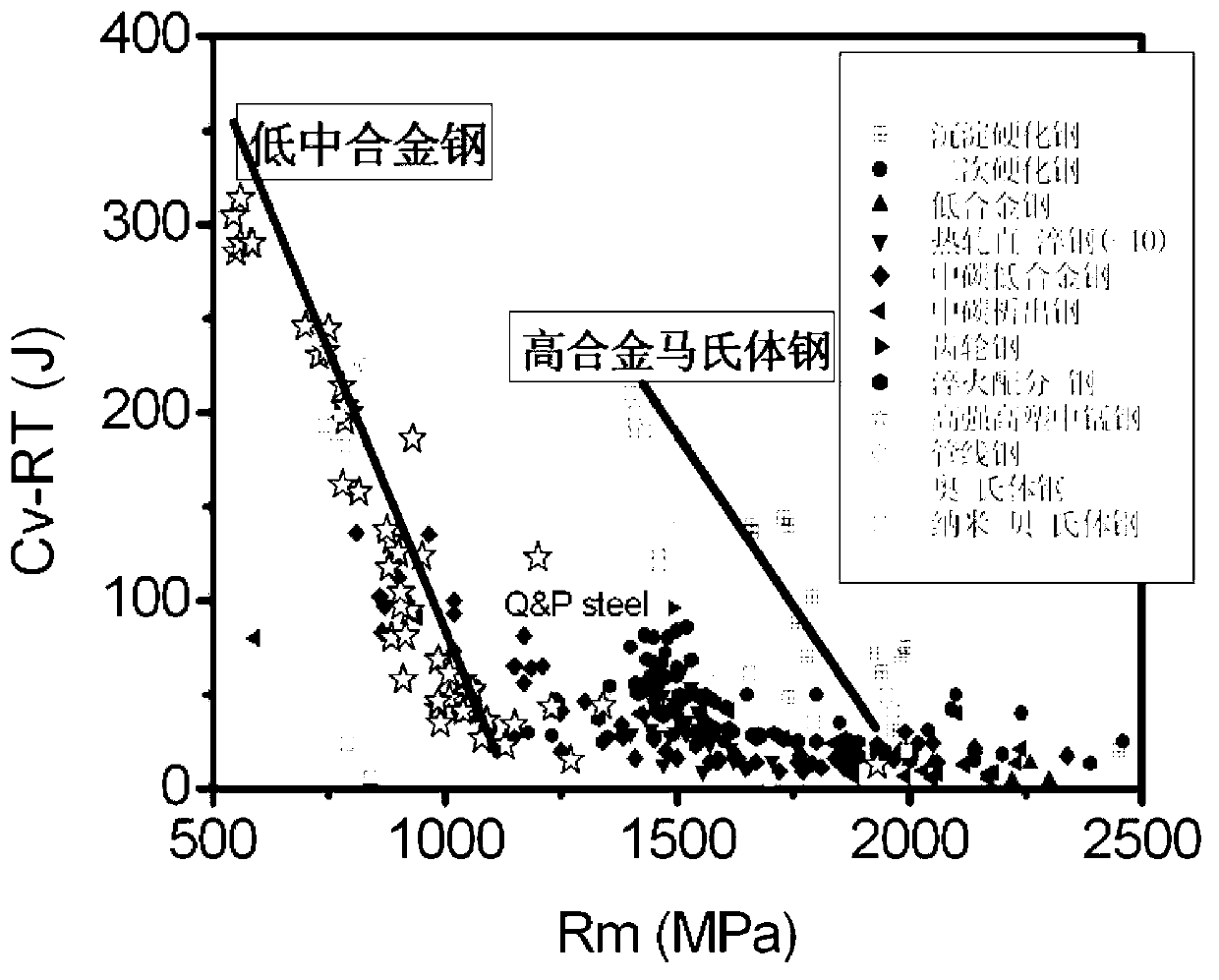

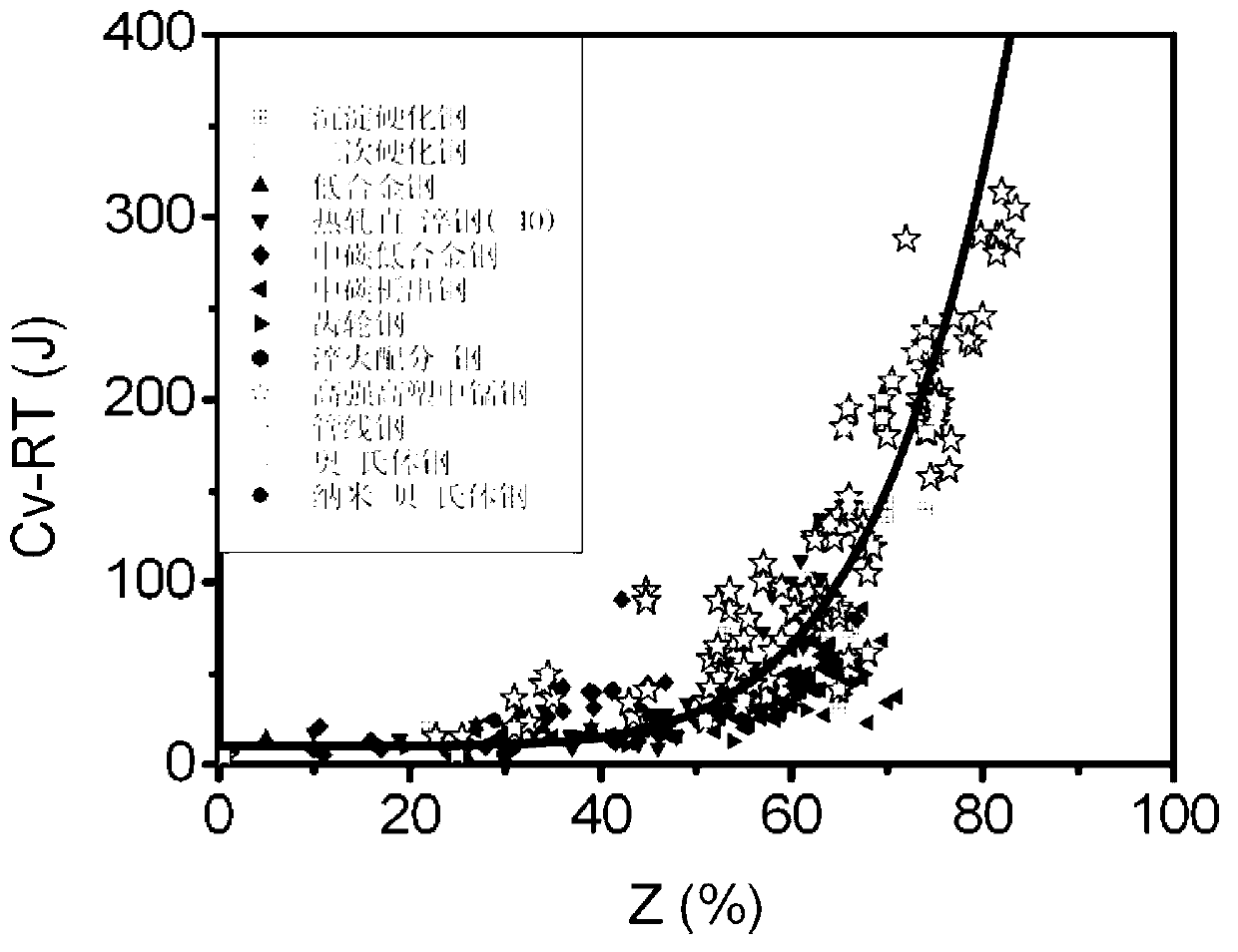

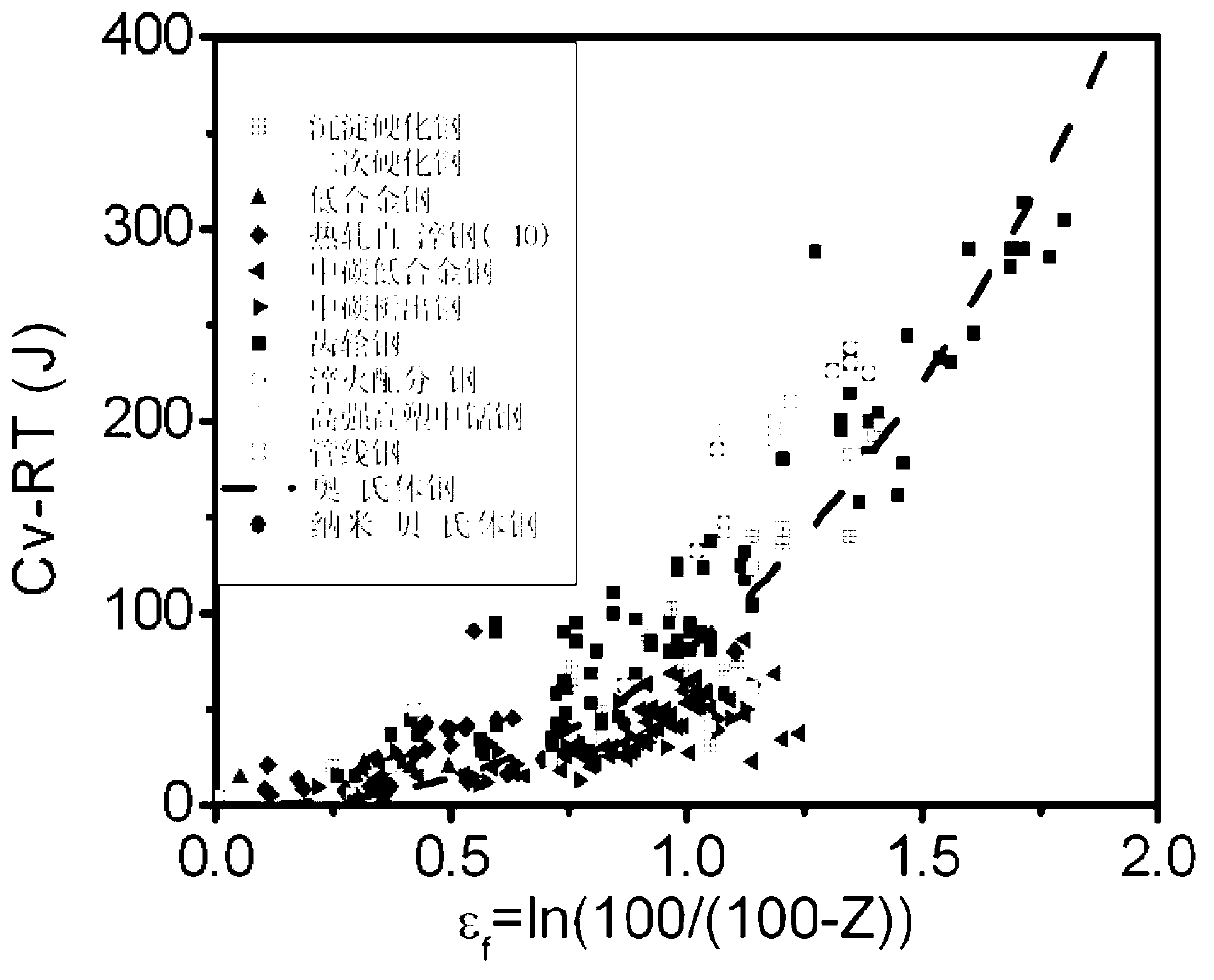

The invention provides a lamellar double-phase high-strength and high-toughness steel and a preparation method thereof, belonging to the technical field of the high-strength and high-toughness steel. The steel has the following chemical components: 0.01-0.5 wt % C, 1.0-10.0 wt % of Mn, 1.0-6.0 wt % of Al, less than or equal to 0.020 wt % of P, less than or equal to 0.02 wt % of S, and the balance being Fe and unavoidable impurities. A preparation technology comprises smelting and solidification of steel, forging or hot rolling and hot continuous rolling of casting blank or casting ingot, and annealing of forged and hot-rolled products. The steel has advantages of easy industrial production, low cost, high strength and high toughness.

Owner:CENT IRON & STEEL RES INST

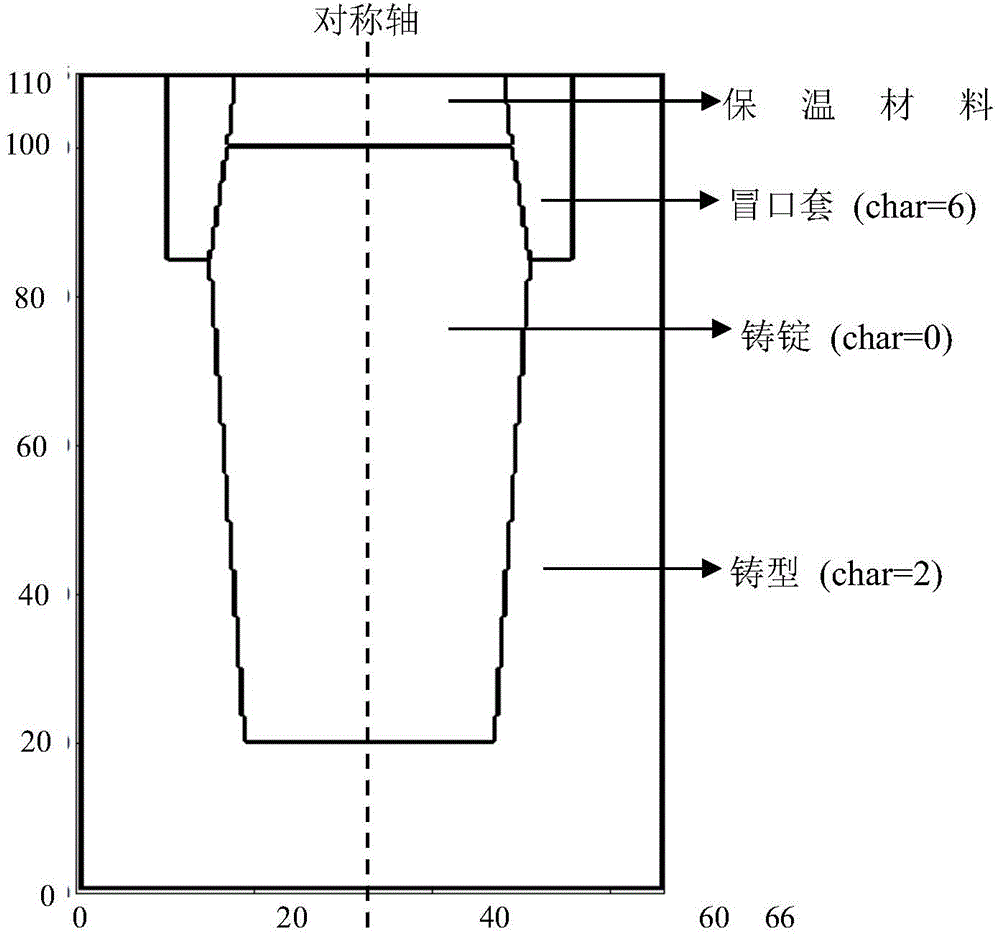

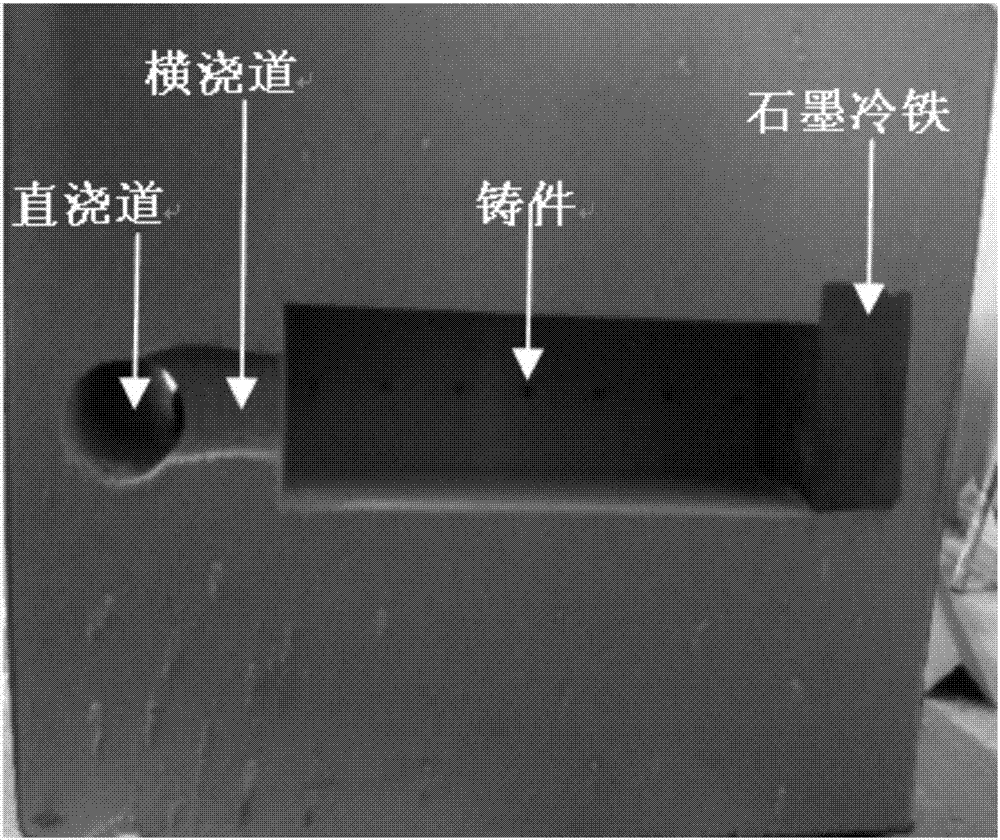

Ingot casting macrosegregation numerical simulation method

InactiveCN104881588AImprove qualityComprehensive forecastSpecial data processing applicationsMacroscopic scaleIngot casting

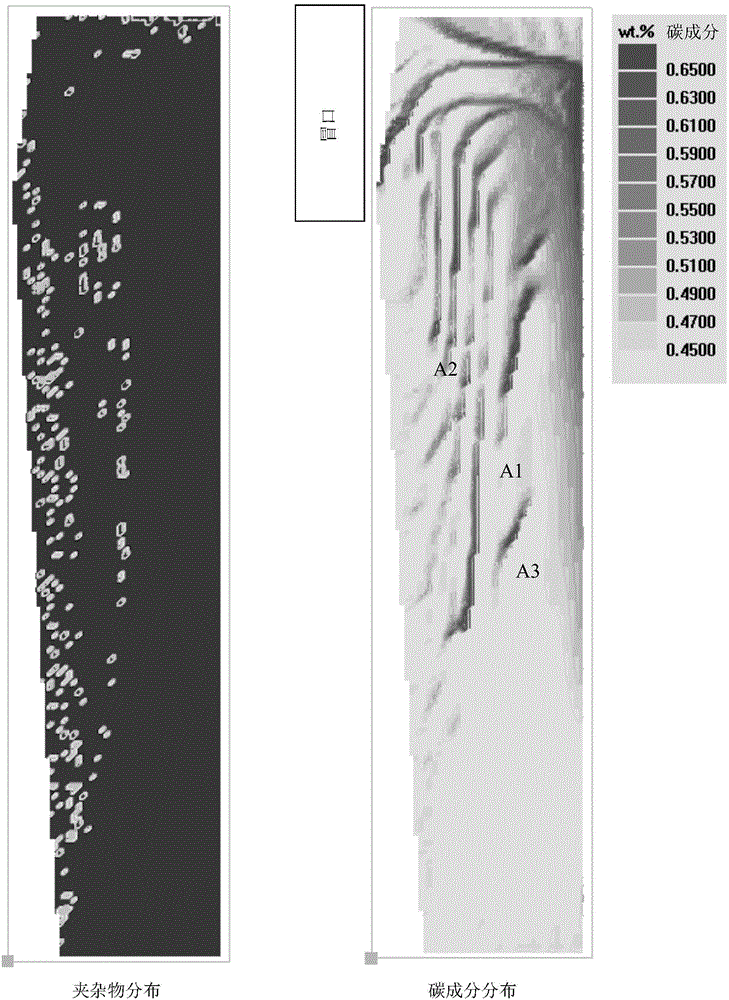

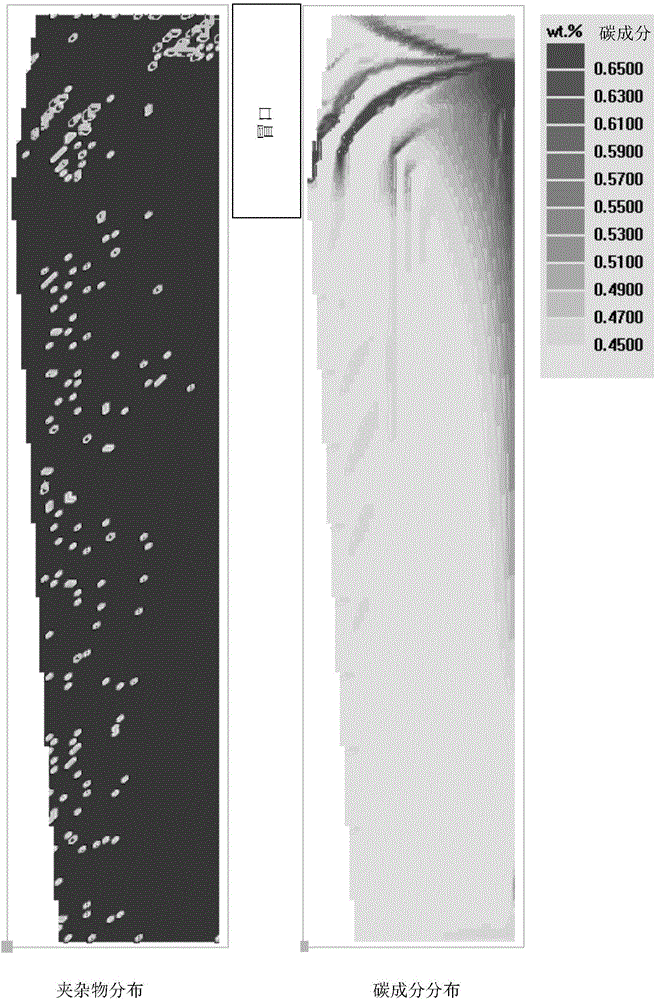

The invention discloses an ingot casting macrosegregation numerical simulation method and belongs to the field of macrosegregation prediction. The problem that macrosegregation formed under the combined action of different physical mechanisms cannot be accurately predicted by existing macrosegregation calculation is solved. The ingot casting macrosegregation numerical simulation method comprises the steps that macroscale mesh generation is carried out on an ingot casting system to form a series of computing grids, and the positions of impurities in the ingot casting system in ingot casting grids are set; for the ingot casting grids, the impurity speed distribution, the cast ingot inner temperature distribution and cast ingot inner average composition distribution are obtained through the energy conservation equation, the composition conservation equation, the momentum conservation equation and the mass conservation equation; for all the computing grids except for the ingot casting grids, the casting grid energy conservation equation is calculated, and the cast grid inner temperature distribution is obtained; after solidification is finished, and the cast ingot inner average composition distribution is output. The ingot casting macrosegregation numerical simulation method accurately predicts macrosegregation formation, and is applicable to prediction of macrosegregation of sand molds and metal molds of various sizes.

Owner:HARBIN UNIV OF SCI & TECH

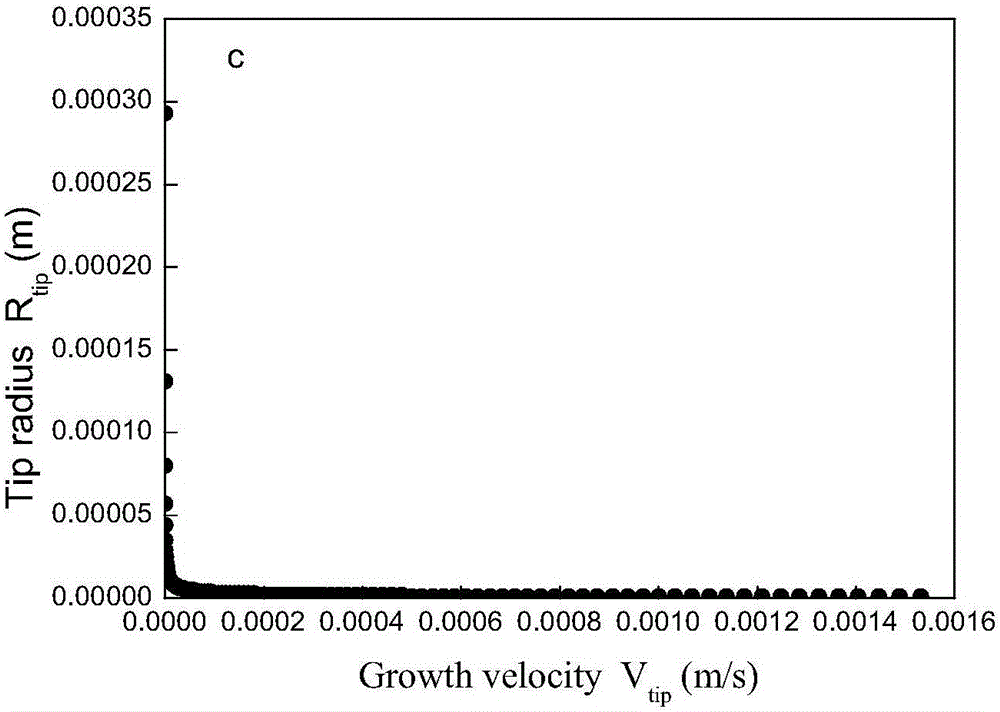

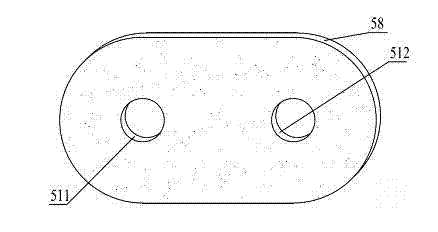

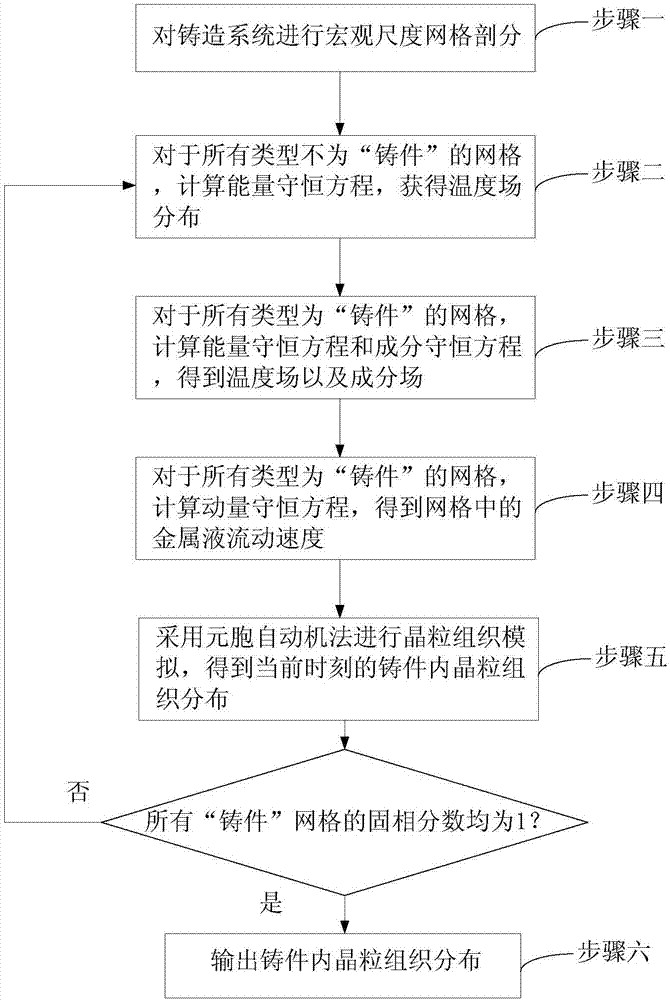

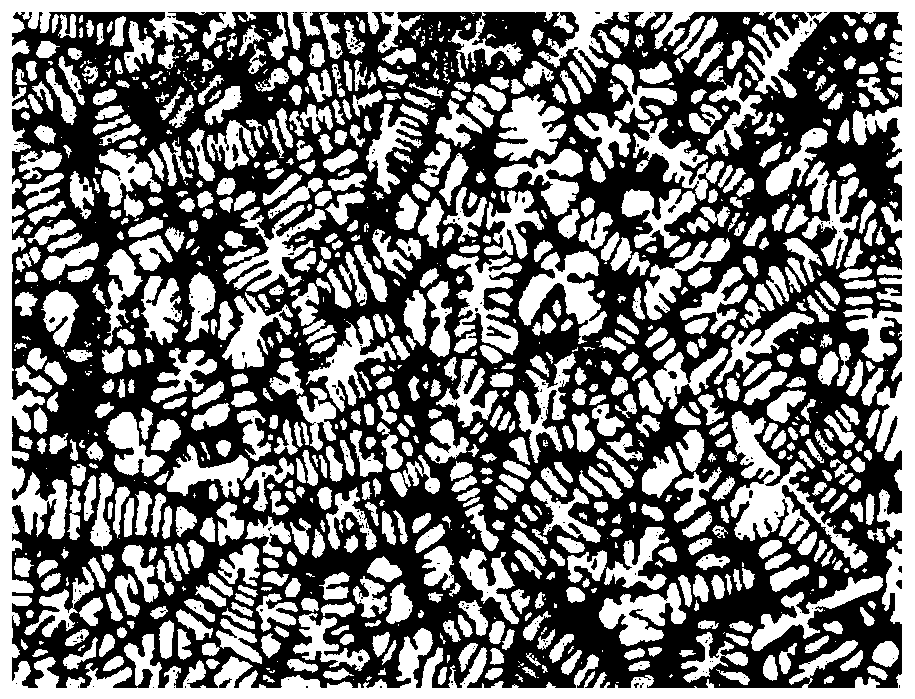

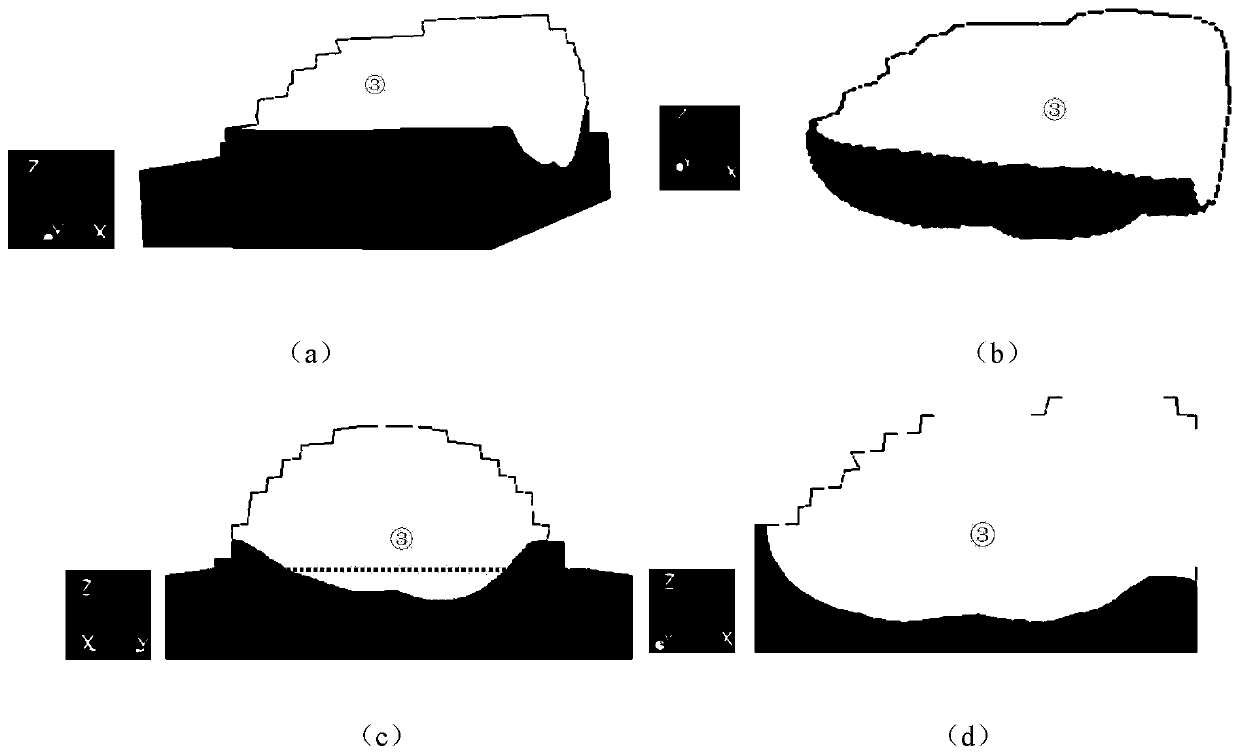

Method for casting grain structure numerical value prediction

InactiveCN105665684AEffective predictionReduce computing timeComplex mathematical operationsGrain structureCrystal growth

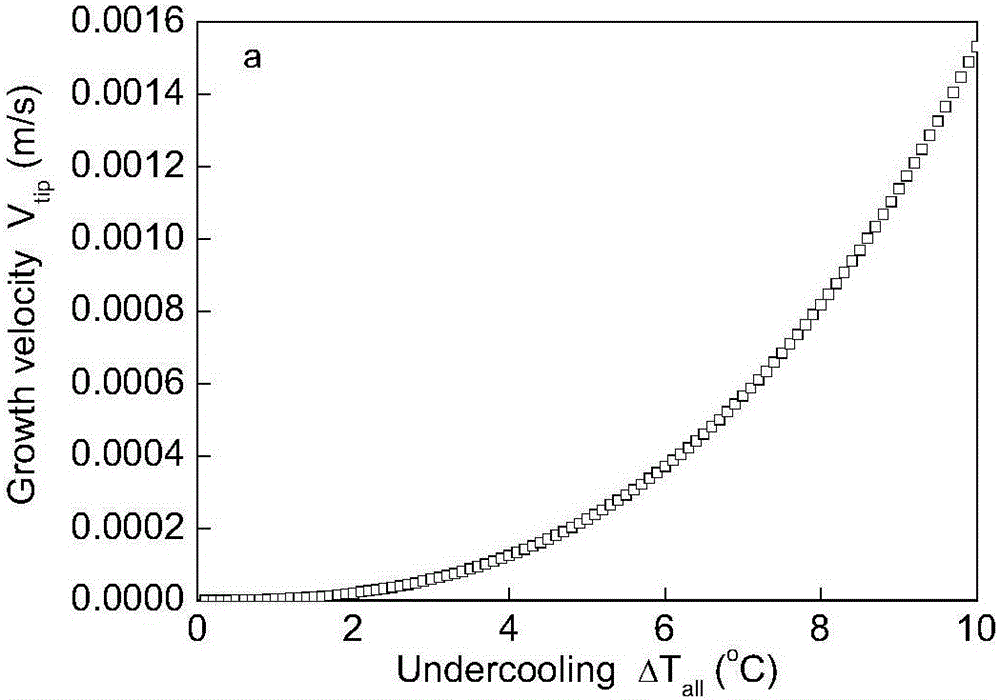

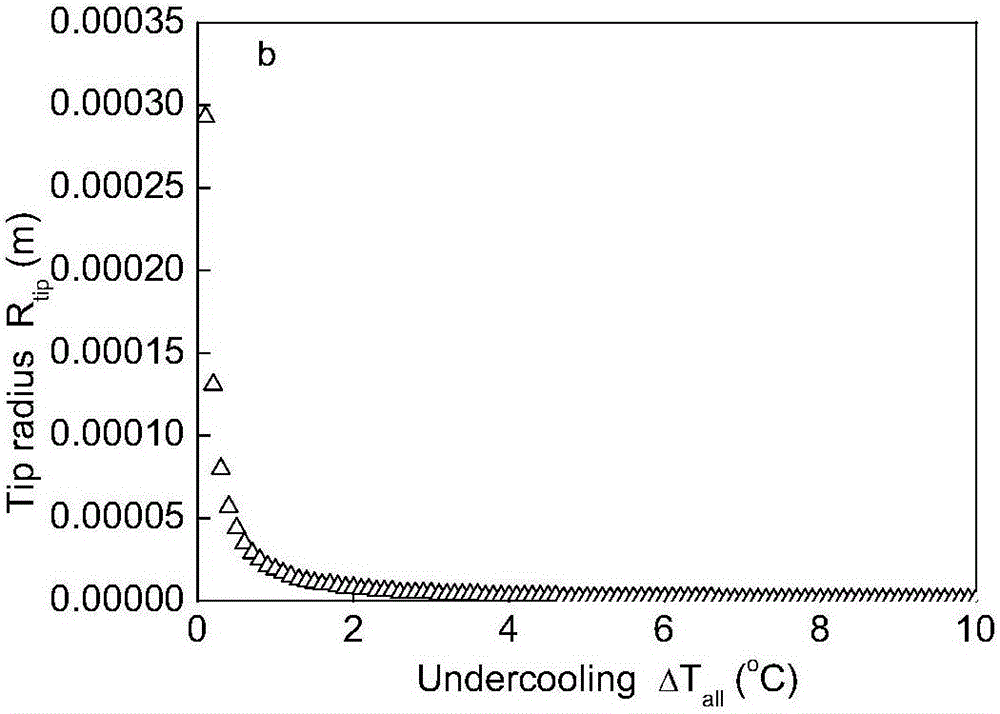

The invention provides a method for casting grain structure numerical prediction, and relates to a prediction method of a casting grain structure. The method aims at solving the problems that in existing grain structure numerical prediction, the calculation time is long and the calculation amount is large. The method includes the steps of calculating a dendritic crystal growth kinetics KGT model first, obtaining the dendritic crystal tip radius-dendritic crystal tip growth speed change curve, conducting macro-scale mesh generation on a casting system, only calculating an energy conservation equation for a computational grid (i,j)chan= / 0 to obtain temperature field distribution, calculating a momentum conservation equation for a computational grid (i,j)chan=0 to obtain the metal liquid flowing speed in the computational grid, judging whether the computational grid (i,j)chan=0 is located on the solidification front or not, calculating the solidification front temperature gradient and the solidification front movement speed corresponding to the grid if yes, and outputting distribution of a grain growth morphology identification grain in a casting till solidification ends. The method is suitable for casting grain structure numerical prediction.

Owner:HARBIN UNIV OF SCI & TECH

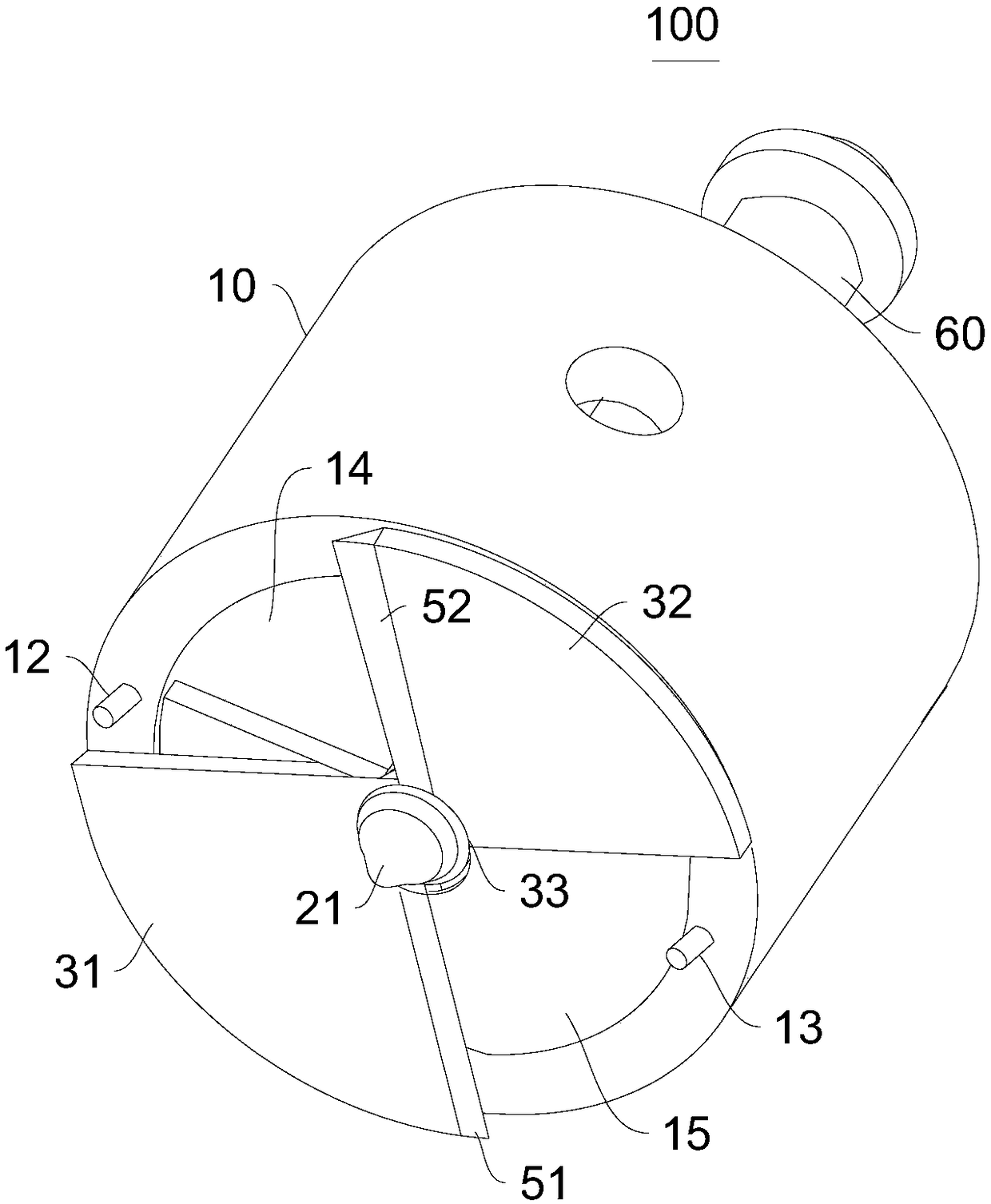

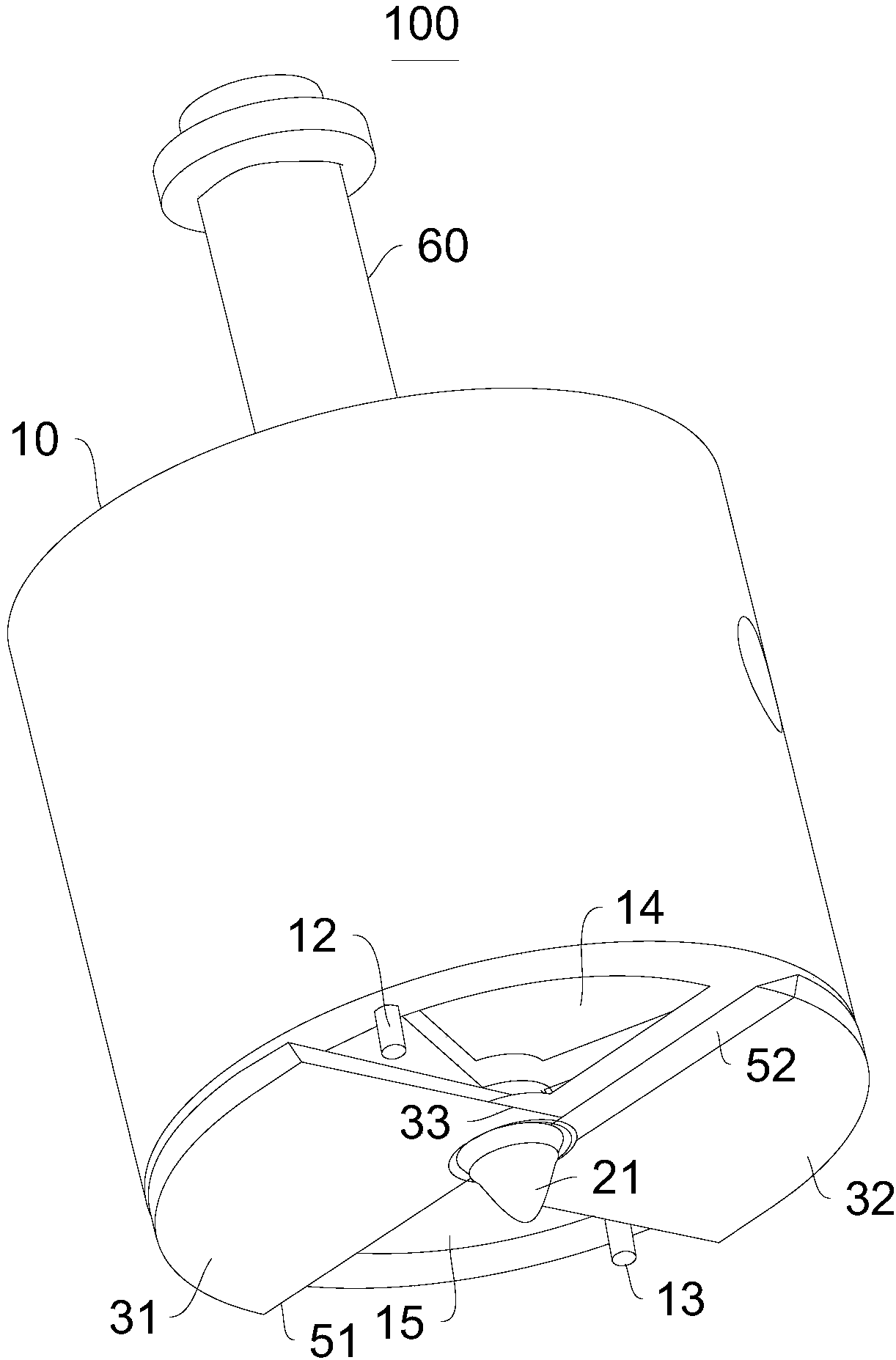

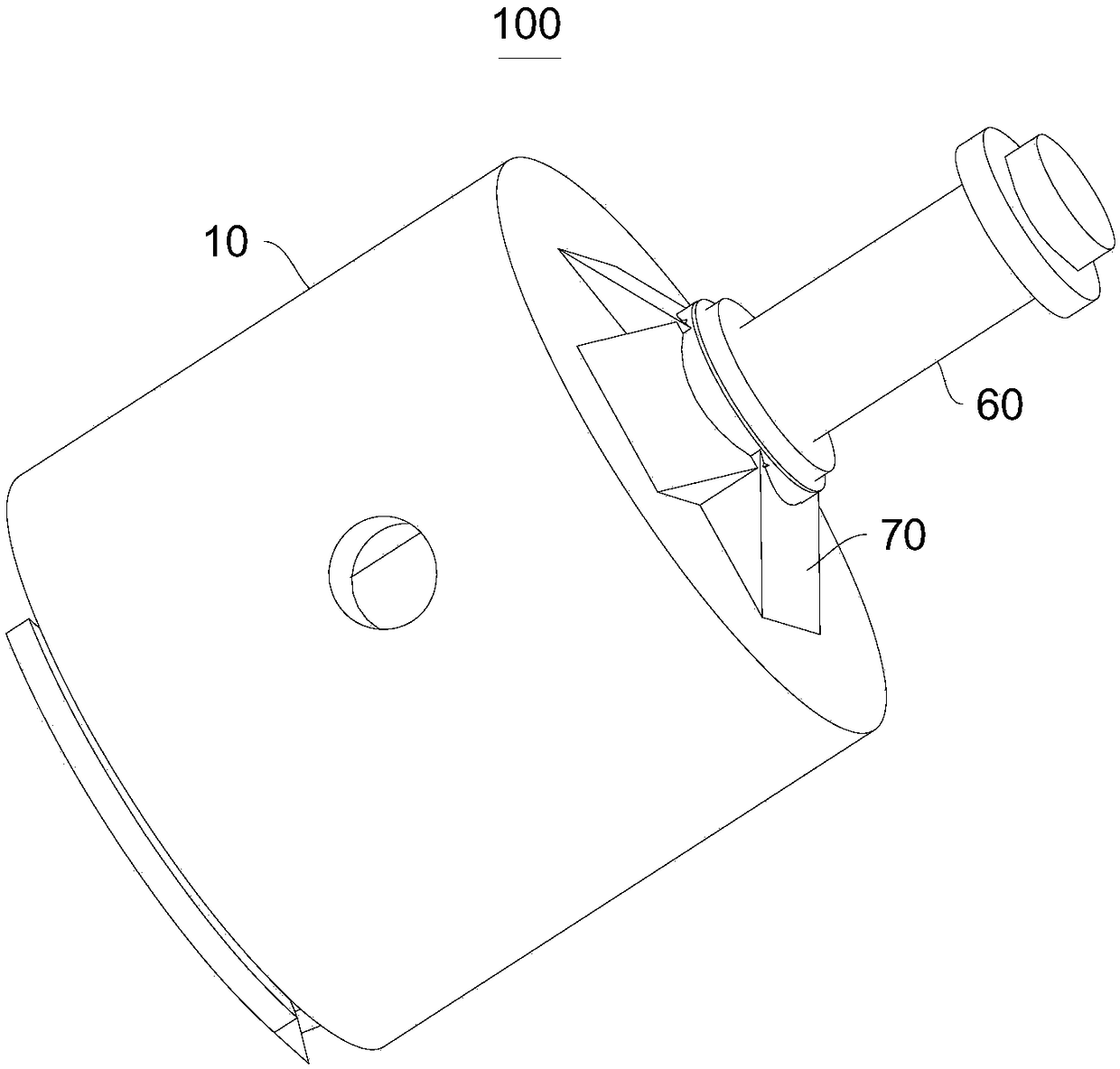

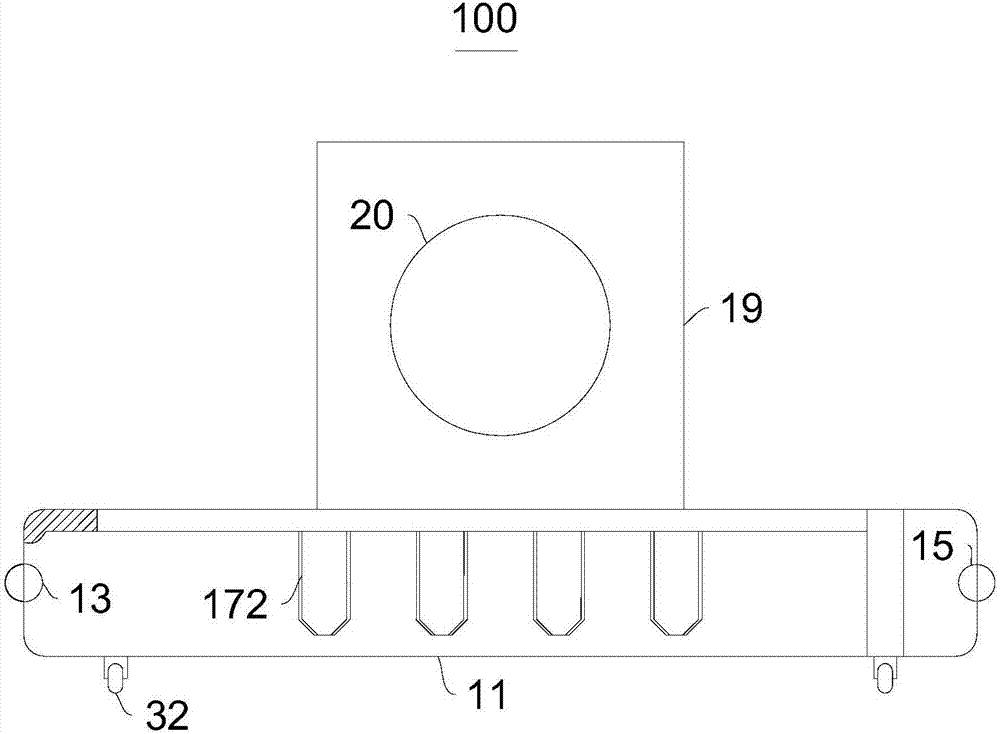

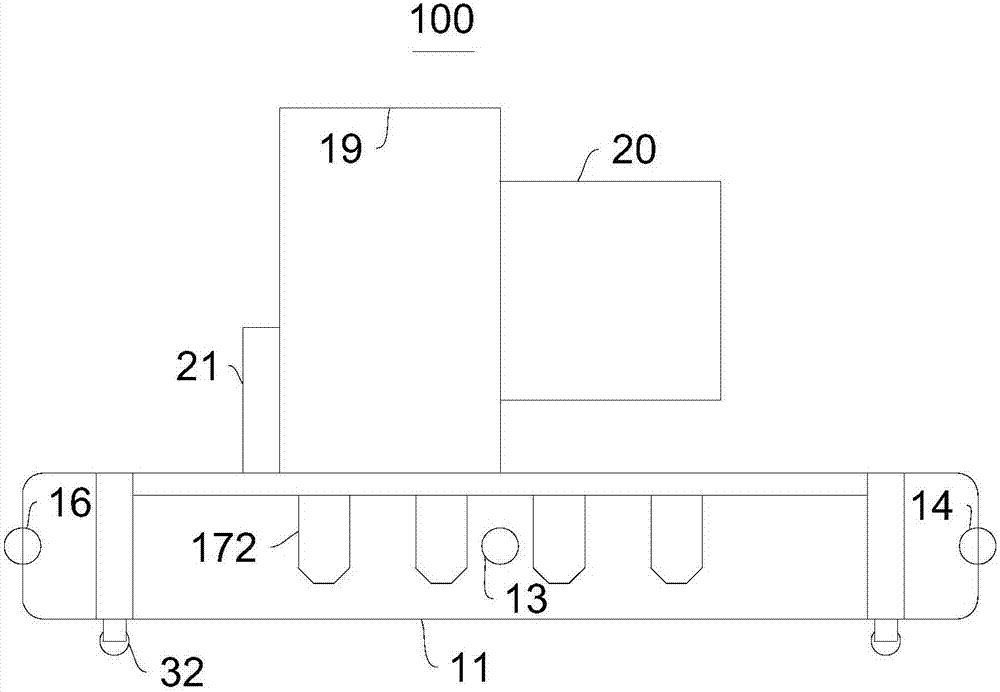

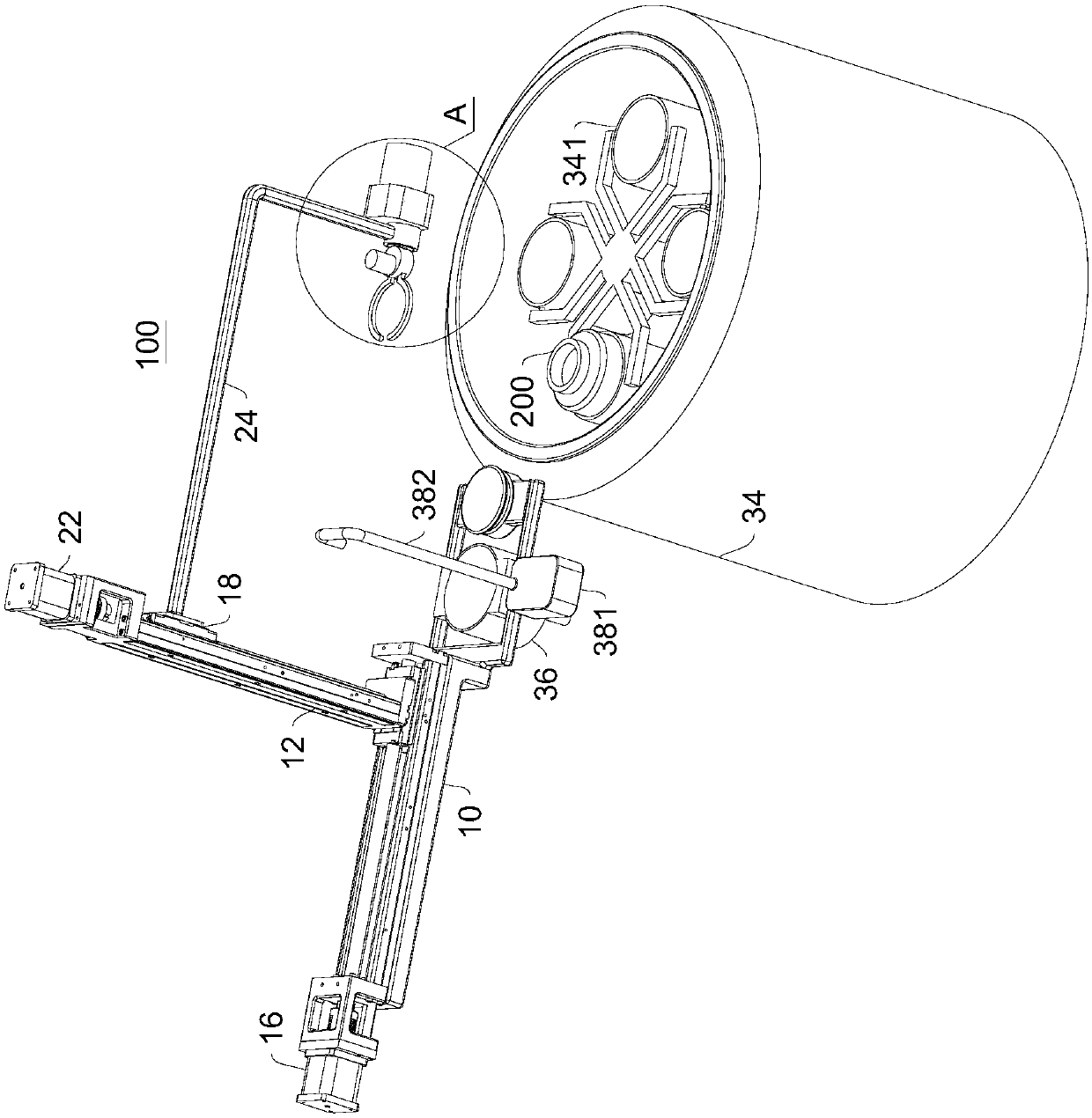

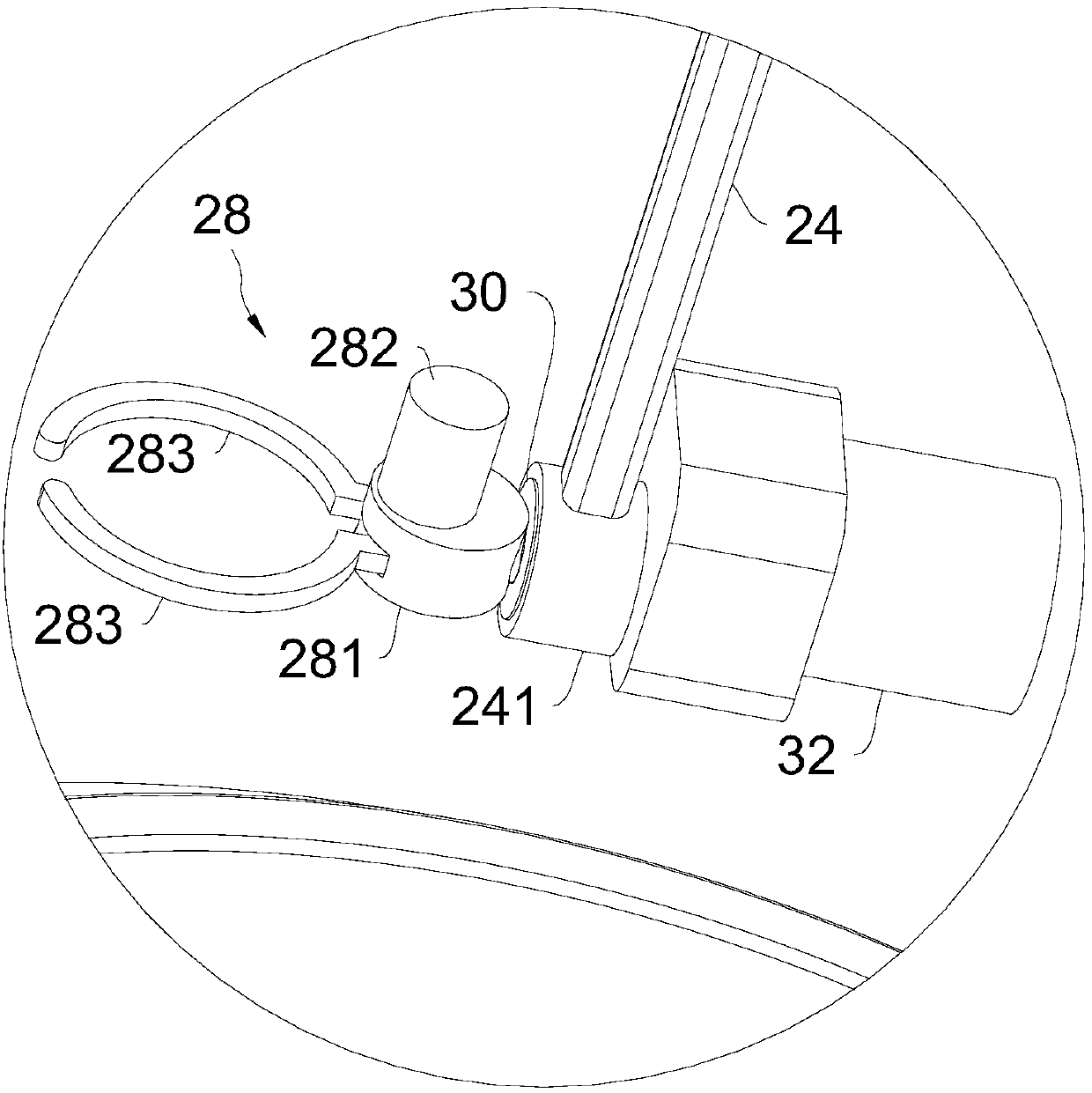

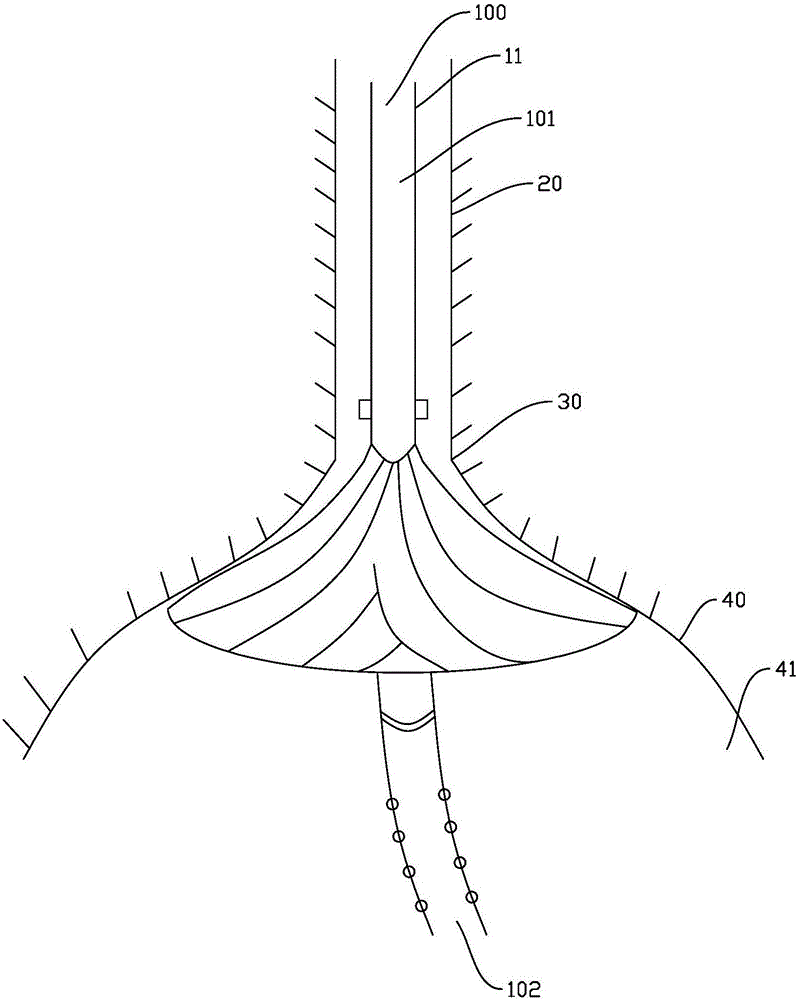

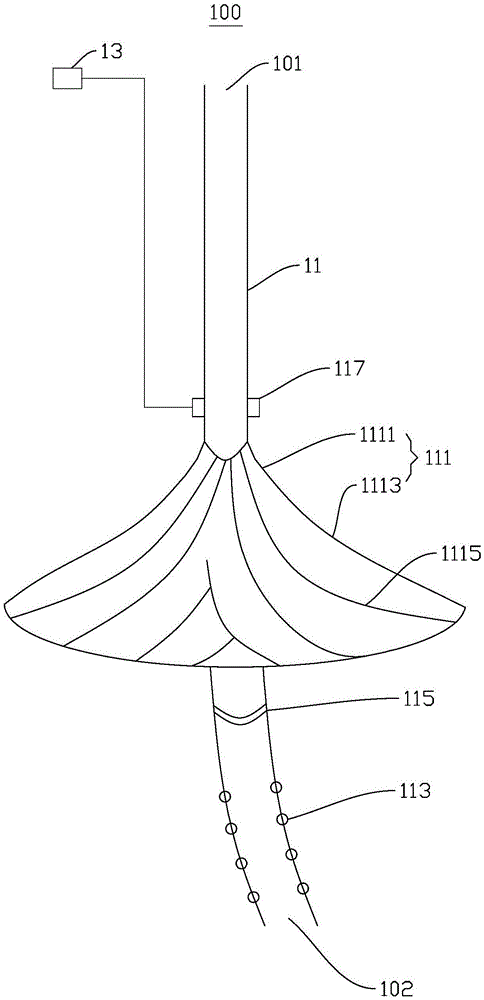

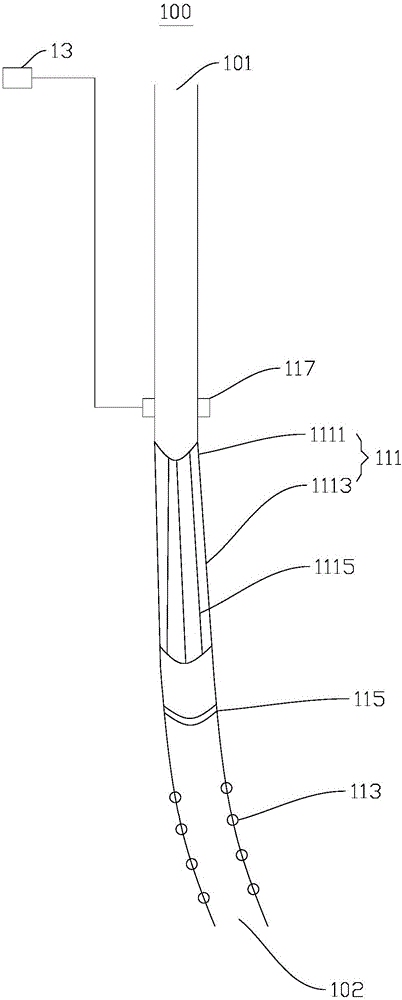

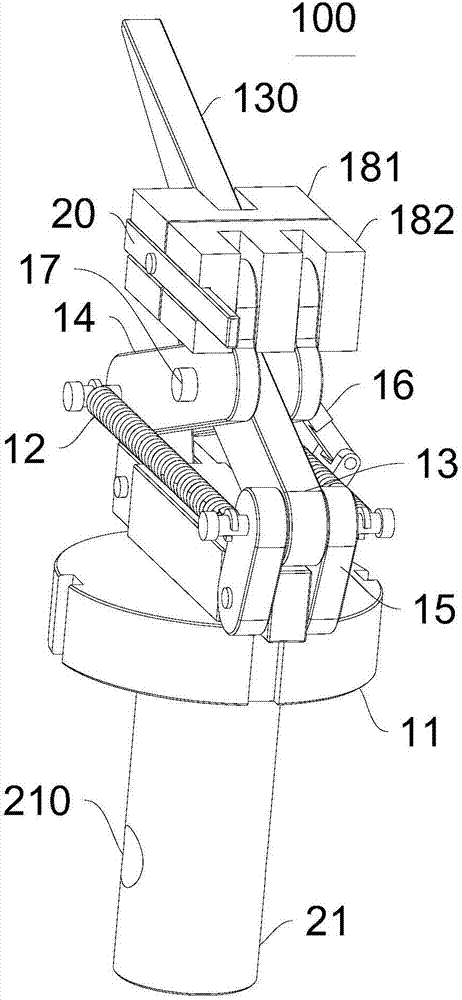

Drill barrel device and drilling machine

PendingCN108086913AImprove primary porosityReduce sediment thicknessDrill bitsConstructionsKnife bladesDrill bit

The invention provides a drill barrel device and a drilling machine, and belongs to the technical field of drilling machines. The drill barrel device comprises a drill barrel body, a drill rod and a sealing part. The drill barrel body is provided with a containing cavity, an opening communicated with the containing cavity is formed in the bottom of the drill barrel body, a positioning part is arranged at the bottom of the drill barrel body, one end of the drill rod is connected with the drill barrel body, a drill bit is arranged at the other end of the drill rod, the drill bit stretches out ofthe containing cavity, the sealing part is rotationally connected to the drill rod, and the sealing part is provided with a drilling blade. By means of the drill barrel device, sediment at the bottomof a pile foundation can be cleaned away, the thickness of the sediment at the bottom can be reduced, the one-time pore-forming rate of the pile foundation is increased, and meanwhile the economic cost is greatly reduced. The drill barrel device is reasonable in structural design, good in overall use effect and high in market application potentiality. The drilling machine comprises the drill barrel device and has all the functions of the drill barrel device.

Owner:CHINA FIRST HIGHWAY ENG +1

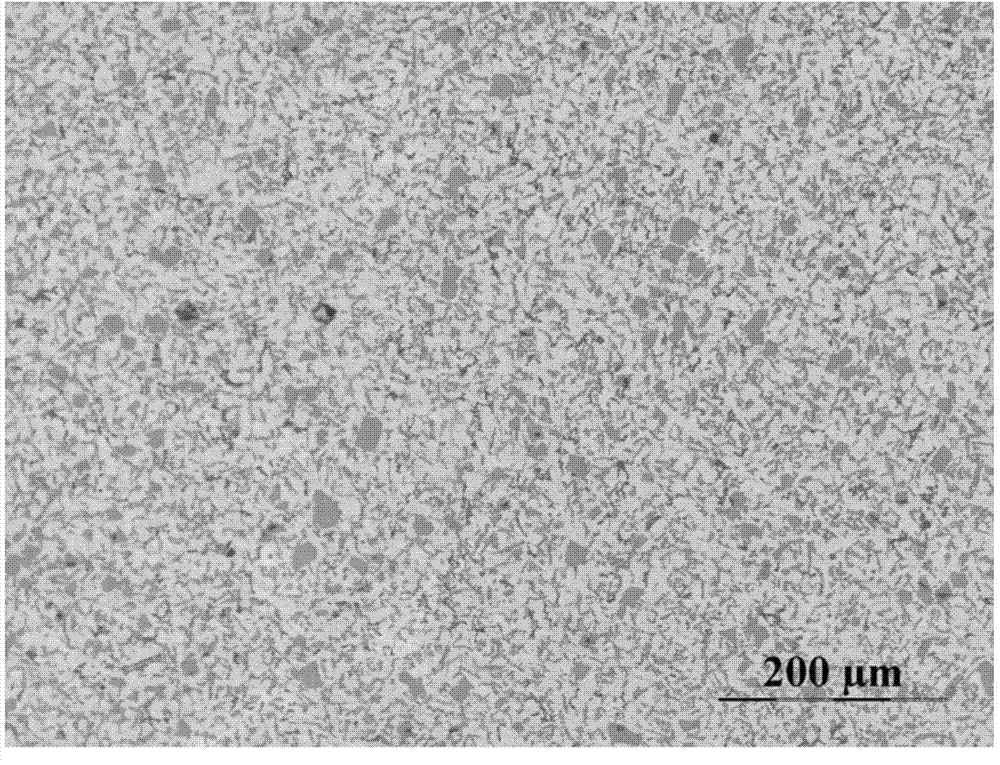

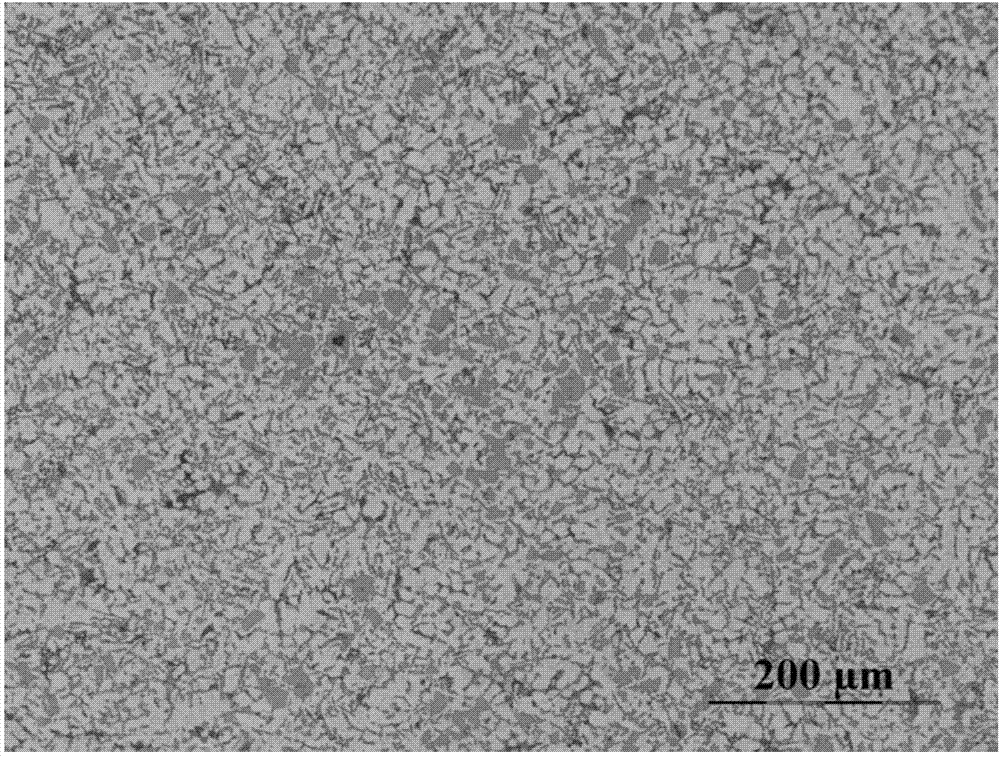

Preparation method for primary-silicon-refinement high-silicon aluminum alloy rheological slurry

The invention discloses a preparation method for primary-silicon-refinement high-silicon aluminum alloy rheological slurry. The preparation method concretely comprises the steps that an aluminum alloy casting coating is smeared on the inner wall of a mechanical roller, dried and preheated; the tilt angle, relative to the ground horizontal line, of the mechanical roller is set to be 10 degrees-45 degrees, and the stirring rate is set to be 20 r / min-250 r / min; with the temperature of a high-silicon aluminum alloy melt kept at 30DEG C-50 DEG C above the liquid line, the high-silicon aluminum alloy melt is cast quickly into the mechanical roller and stirred to obtain the rheological slurry. The rheological slurry flowing out after being stirred is stored in a holding furnace, furnace temperature is kept at a superheat degree of 5 DEG C-15 DEG C above the liquid line, and immediately subsequent casting formation is performed on the rheological slurry within 10 seconds-20 seconds. The preparation method is short in treating process, high in efficiency and beneficial to industrial production. The prepared slurry can be made into castings with high surface smoothness and excellent mechanical properties by the adoption of high pressure, extrusion casting and other forming technologies, and therefore the slurry is an excellent choice for preparing high-quality high-silicon aluminum alloy and has huge market application potential.

Owner:SHANGHAI JIAO TONG UNIV

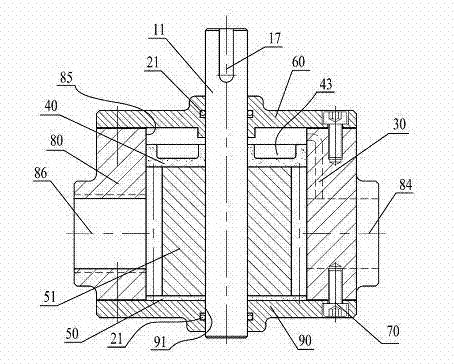

Self-sealing gear pump

ActiveCN102927000AGood value for moneyAchieve super mirrorRotary piston pumpsRotary piston liquid enginesInternal pressureGear pump

The invention relates to a self-sealing gear pump. The self-sealing gear pump is characterized in that a suction inlet of an internal thread and a discharge port of the internal thread are positioned on two sides of a pump body, the two end faces of the pump body are perpendicular to a dual-semicircle hole, a front outer end cover and a rear outer end cover cover the two end faces respectively, and the front and rear outer end covers and the two end faces are fastened by end cover screws; a main alloy gear is meshed with a slave alloy gear, the pump body is provided with an internal pressure channel, one end of the internal pressure channel is communicated with a cavity on the back of a compensating disc, and the other end of the internal pressure channel is communicated with a discharge port of the internal thread; composite material compensation discs are arranged between the main alloy gear and the front outer end cover as well between the slave alloy gear and the front outer end cover; and composite material friction discs are arranged between the main alloy gear and the rear outer end cover as well as between the slave alloy gear and the rear outer end cover; and both the composite material compensation discs and the composite material friction discs are made of a composite material formed by Fe / Al intermetallic compound and Al2O3 ceramic, and both the main alloy gear and the slave alloy gear are made of Nb (niobium) micro-alloying high strength powder metallurgy material.

Owner:NANTONG WOTELI MASCH MFG CO LTD

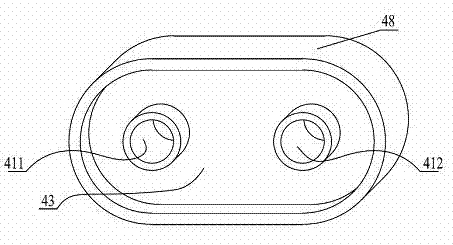

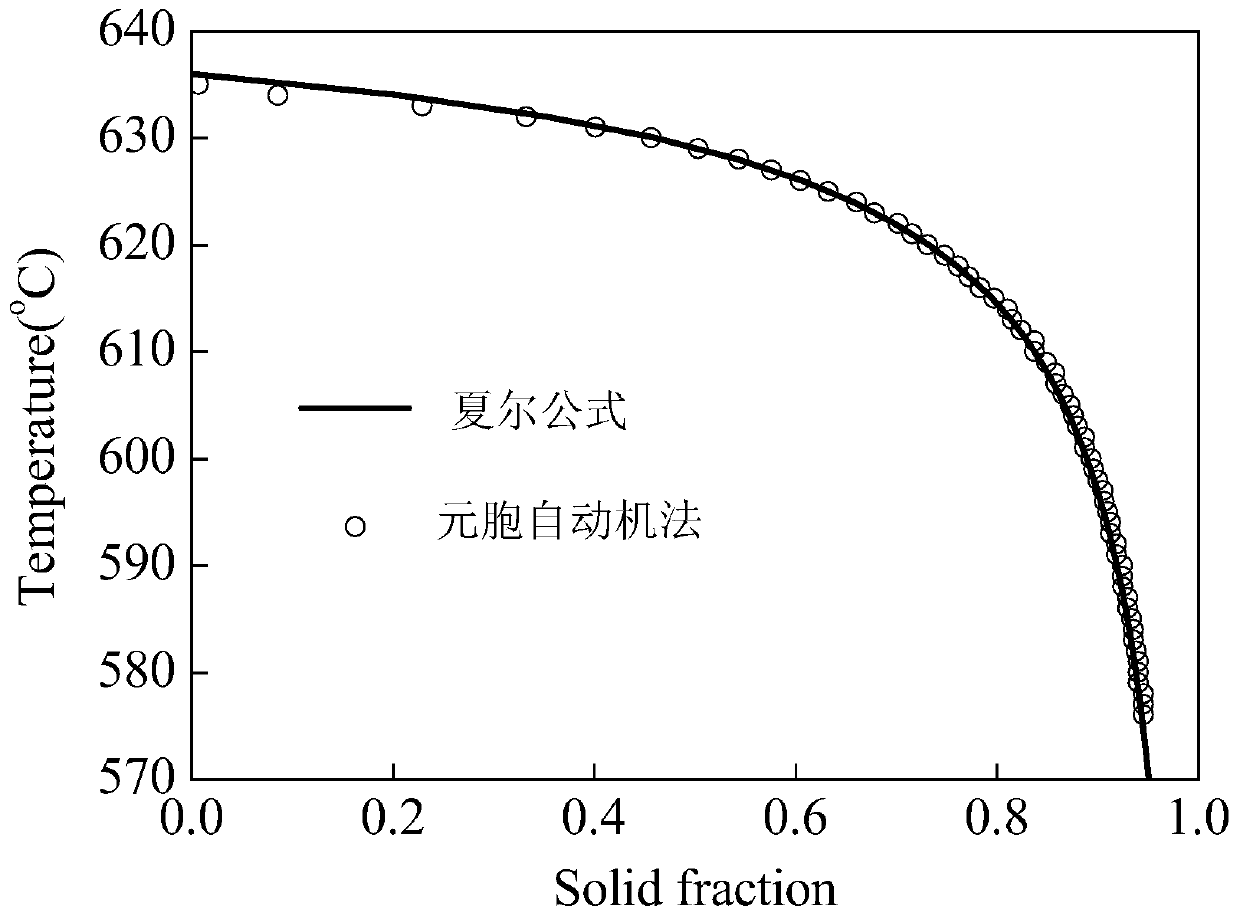

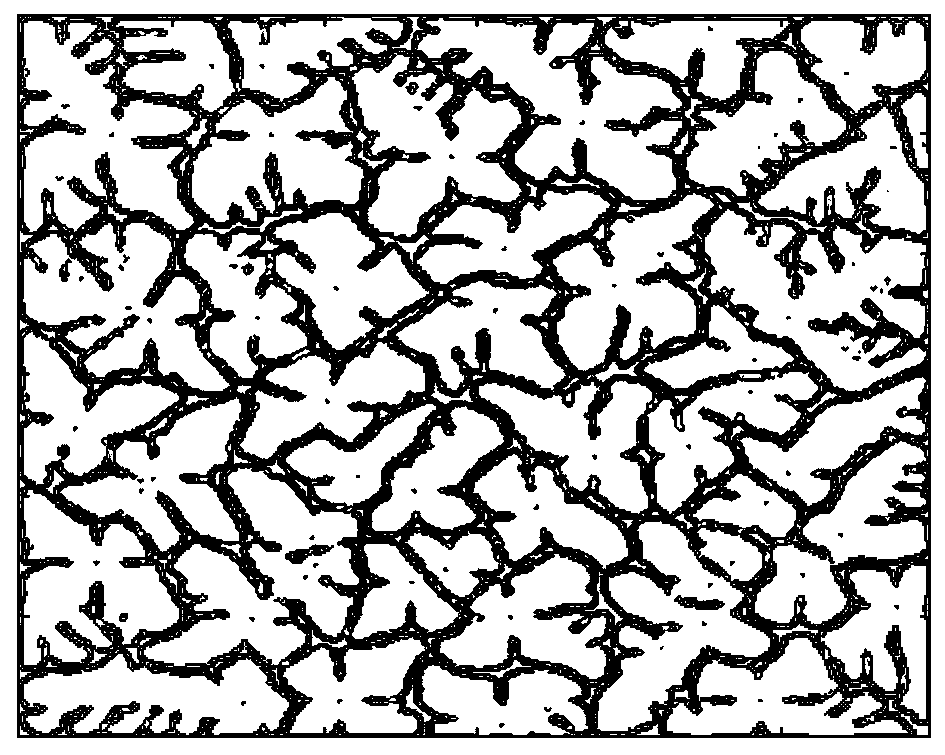

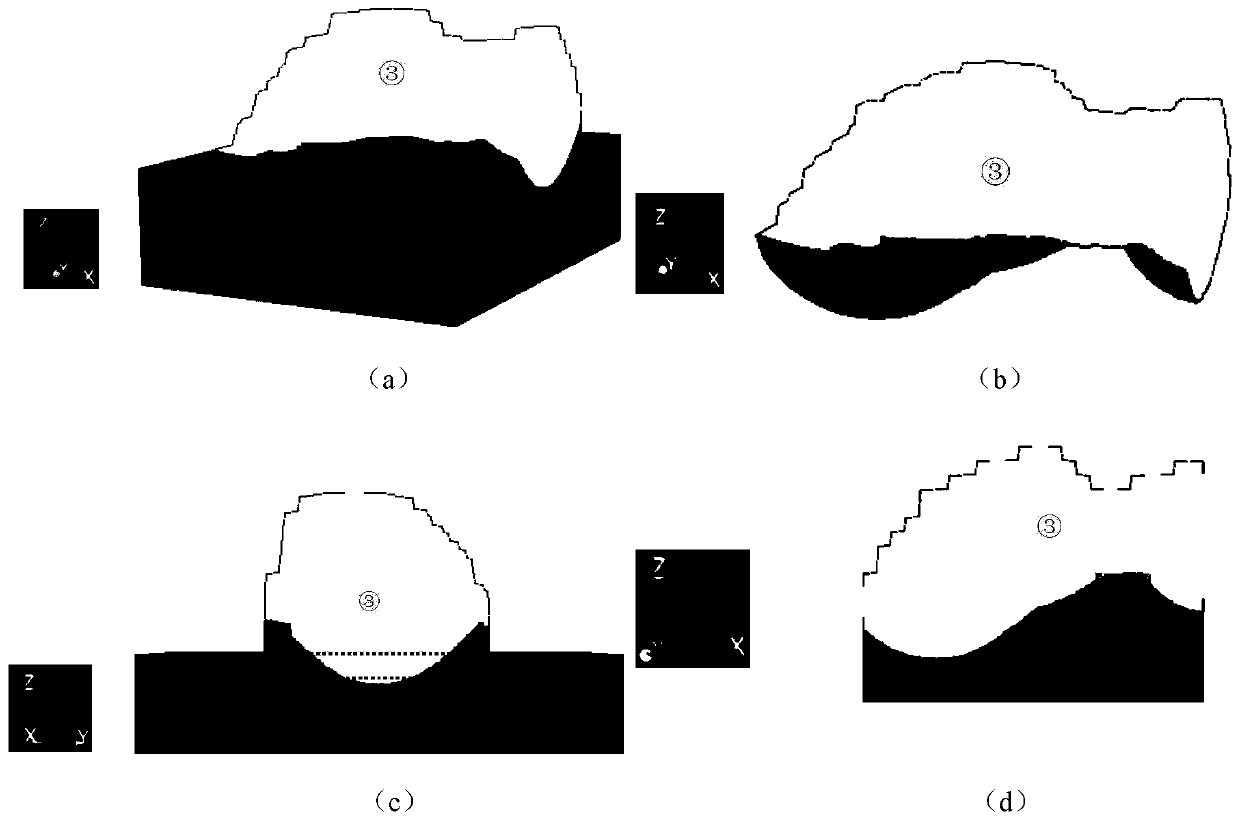

Inoculated alloy grain structure numerical value prediction method

InactiveCN106944607AReduce computing timeImprove computing efficiencyDesign optimisation/simulationSpecial data processing applicationsCellular automationAdditive ingredient

The invention relates to an inoculated alloy grain structure numerical value prediction method, belongs to a grain structure simulation prediction method and aims to overcome the defects that in the prior art, calculation efficiency of a three-dimensional macroscopic field in inoculated alloy grain structure numerical value prediction is not high, and the grain structure cannot be accurately predicted. The inoculated alloy grain structure numerical value prediction method provided by the invention includes the steps that macroscale grid division is performed on a casting system; for all non-casting grids, an energy conservation equation is calculated, and temperature field distribution is obtained; for all casting grids, an energy conservation equation and an ingredient conservation equation are calculated; for the casting grids, a momentum conservation equation is calculated; a cellular automaton method is adopted for grain structure simulation, and the grain structure distribution in a casting at the current moment is obtained; the above steps are repeated till the solid fraction corresponding to all the casting grids is 1; and the grain structure distribution in the casting is output finally. The inoculated alloy grain structure numerical value prediction method is suitable for simulation and numerical value prediction of the inoculated alloy grain structure.

Owner:HARBIN UNIV OF SCI & TECH

Body-centered cubic alloy microscopic segregation numerical prediction method

ActiveCN110263418AEliminate the effects ofImprove computing efficiencyDesign optimisation/simulationSpecial data processing applicationsData fileAlloy

The invention discloses a body-centered cubic alloy microscopic segregation numerical prediction method, and relates to a body-centered cubic alloy microscopic segregation numerical prediction method. The objective of the invention is to solve the problem that the microcosmic segregation formation of the body-centered cubic alloy cannot be accurately predicted by the existing method. The method comprises the following steps: 1, carrying out micro-scale mesh generation; 2, the square grids and the three surrounding grids forming a group; 3, completing dendritic crystal growth; 4, determining the state of the grid; 5, determining a dynamic coefficient; 6, further dividing into four local computational domains; 7, calculating nucleation in a local calculation domain; 8, randomly selecting a certain group of pairing grids in the local calculation domain, and judging whether the group has a nucleation phenomenon or not; 9, capturing four groups of surrounding neighbor pairing grids by the mother core grid; 10, calculating parameters; 11, calculating a solute diffusion equation; 12, repeating step 7-11, and outputting a solute component distribution data file; estimating heat treatment time. The method is used for the field of body-centered cubic alloy microscopic segregation numerical prediction.

Owner:HARBIN UNIV OF SCI & TECH

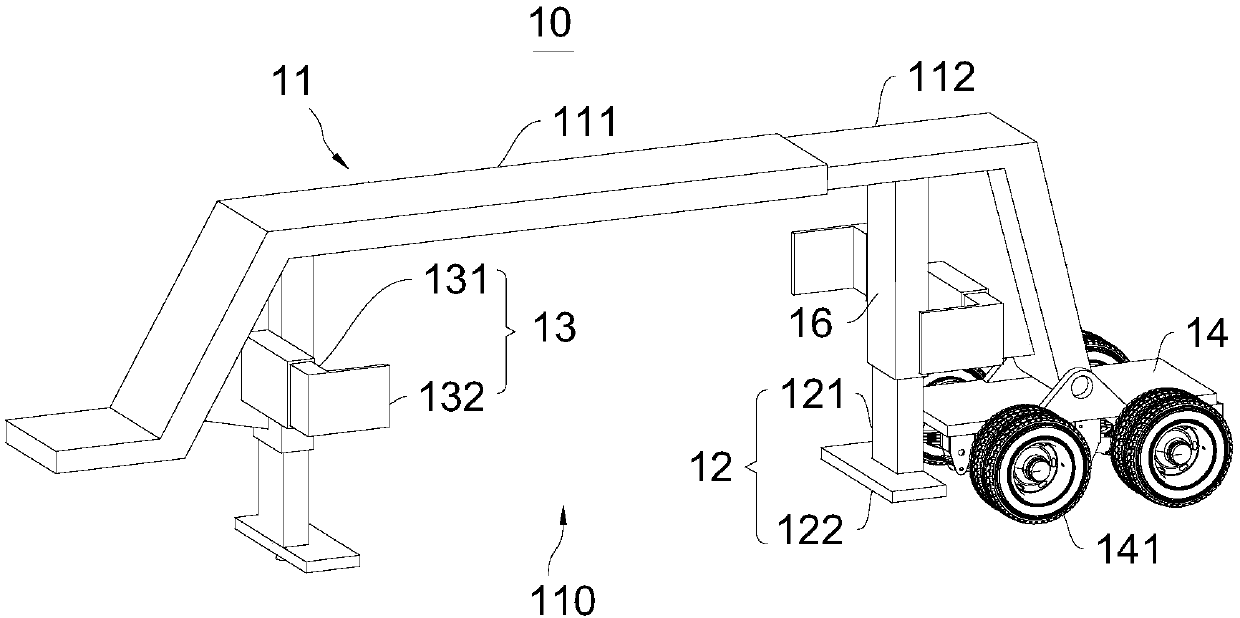

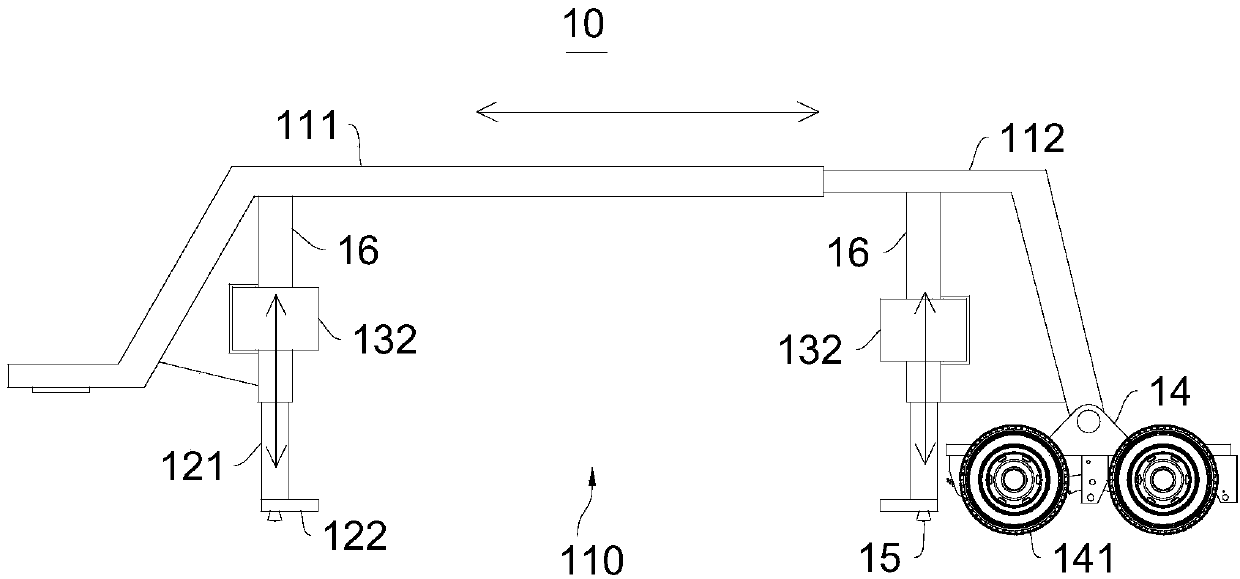

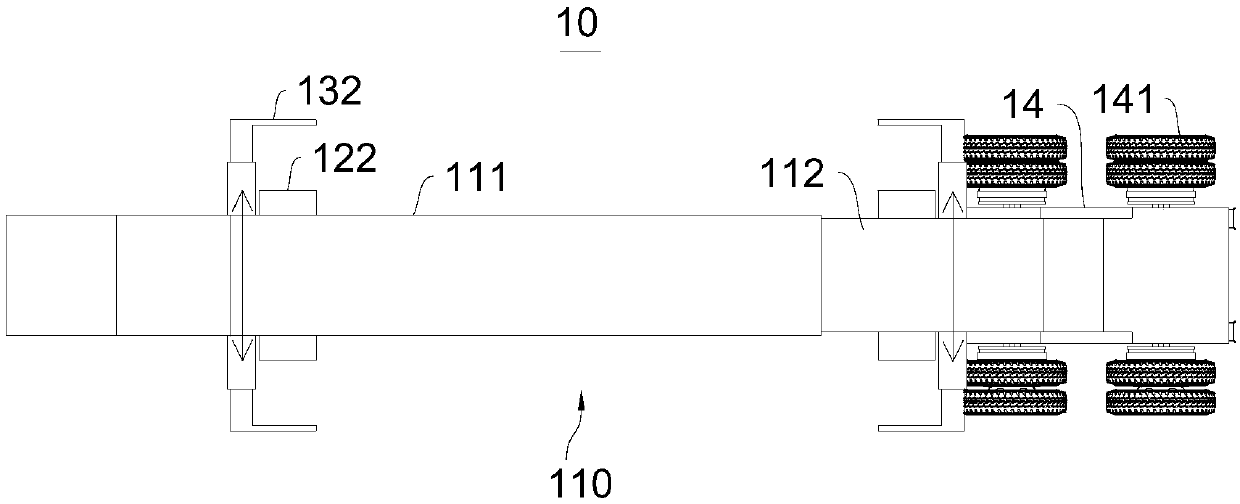

Transportation vehicle body and transportation vehicle

PendingCN107554389ALower center of gravityTransport stableVehicle to carry long loadsLoading-carrying vehicle superstructuresVehicle frameFixed frame

The invention provides a transportation vehicle body and a transportation vehicle and belongs to the technical field of transportation. The transportation vehicle body comprises a frame, fixing devices and a traveling device, wherein the middle portion of the frame is upwardly arched, a loading space for loading goods is formed below the arched middle portion, the fixing devices are connected withthe frame and used for fixing the goods located in the loading space, and the traveling device is connected with the frame. The transportation vehicle body has the advantages that the goods can be loaded below the frame, low overall gravity center and stable transportation are achieved, and the problems of height exceeding and width exceeding are avoided; due to the fact that the goods can be directly loaded and unloaded, hoisting equipment is not needed, and loading and unloading efficiency is increased evidently; the transportation vehicle body is reasonable in structural design and huge inmarket application potential. The transportation vehicle comprises the transportation vehicle body and has all the functions of the transportation vehicle body.

Owner:HUNAN SANY KUAIERJU RESIDENTIAL IND CO LTD

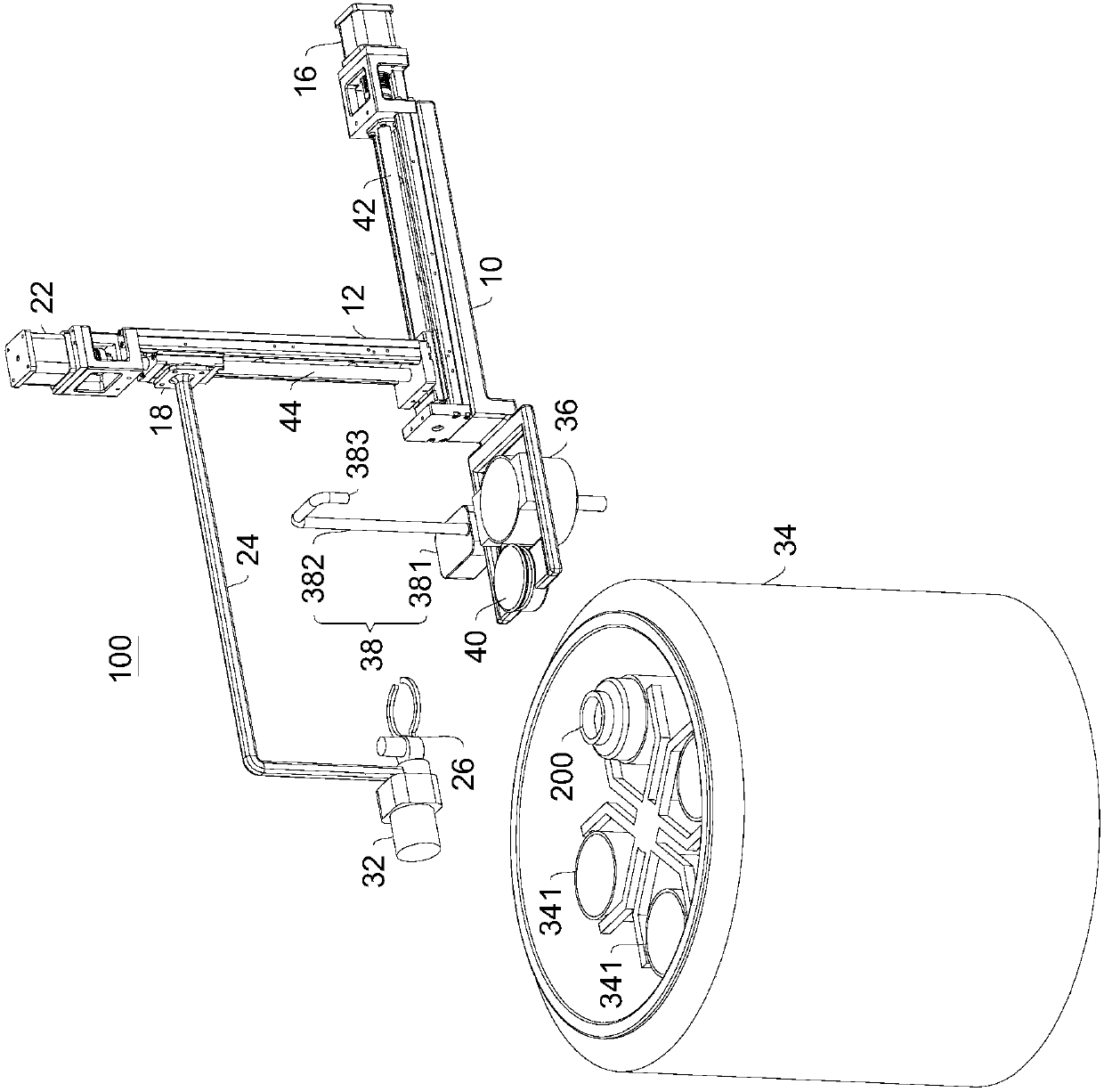

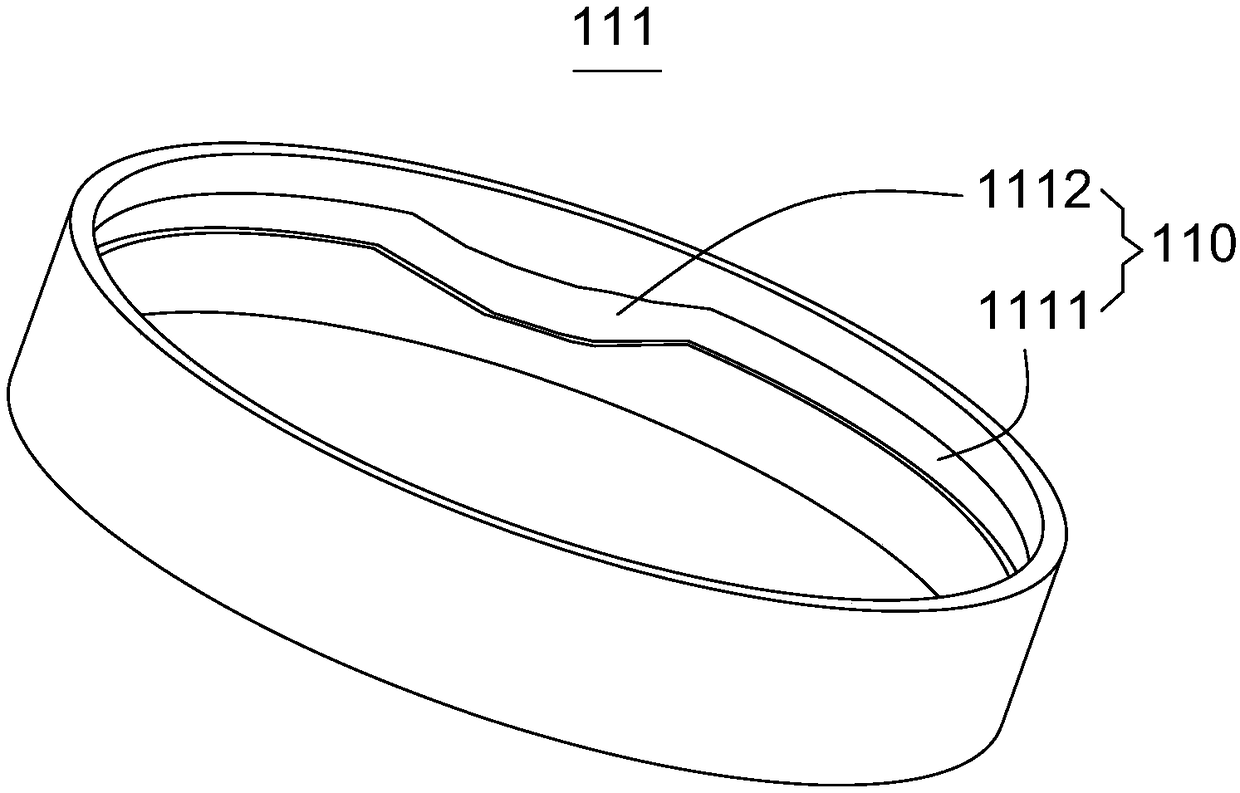

Rim, hub and manufacturing method of hub

PendingCN107901697AImprove fatigue resistanceImprove performanceRimsWheel manufactureEngineeringFlange

The invention provides a rim, a hub and a manufacturing method of the hub and belongs to the technical field of wheels. The rim comprises a rim body, an annular first protrusion is arranged on the edge of the rim body, extends in the direction close to the outer side of the rim body and forms a wheel flange of the rim, and the wheel flange and the rim body are integrally formed. The rim can enhance the anti-fatigue capacity of the hub, after the rim is installed on an automobile, operation is more stable, the performance of the hub is greatly improved, and the rim is reasonable in structural design and huge in market application potential.

Owner:重庆市超群工业股份有限公司

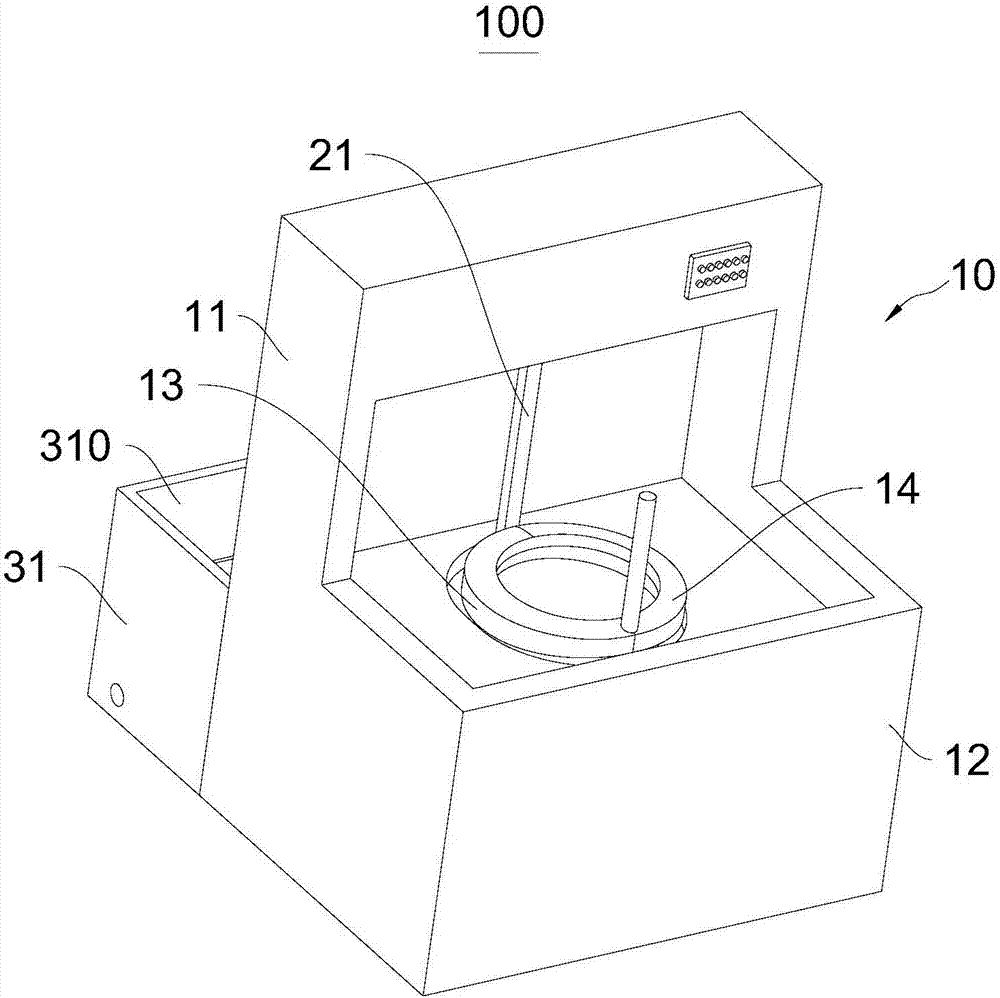

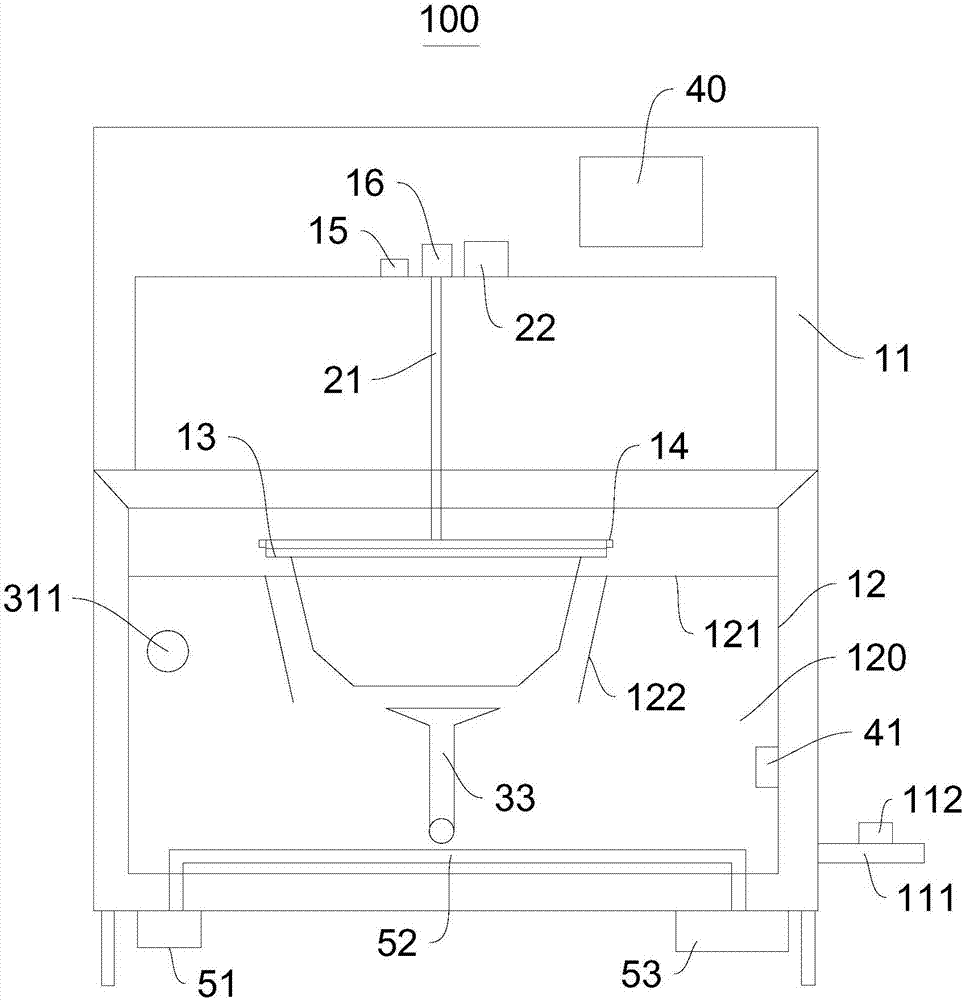

Noodle cooker and noodle cooking equipment

PendingCN107374342ASimple designIngenious designWater-bath cooking vesselsCooking insertsProcess engineeringControl switch

The invention provides a noodle cooker and noodle cooking equipment and belongs to the technical field of food processing. The noodle cooker comprises a cooker body, a pot, a noodle leakage bracket, a noodle leakage unit, a heating system and a control switch used for controlling the heating system to heat noodle cooking water; the cooker body is connected with the pot, and the pot is provided with a first containing cavity used for containing noodle cooking water; the control switch comprises a first switch body and a second switch body, the noodle leakage bracket is slidably arranged on the cooker body and can be close to or array from the first containing cavity, and the noodle leakage unit is detachably erected on the noodle leakage bracket. The noodle cooker is high in automation degree, simple in operation and good in overall use effect; energy consumption is low, and noodles cooked are good in taste through accurate time control; the entire noodle cooker is ingenious in design, simple in operation and large in market application potential; the noodle cooking equipment comprises the noodle cooker and has all the functions of the noodle cooler.

Owner:孟建彬

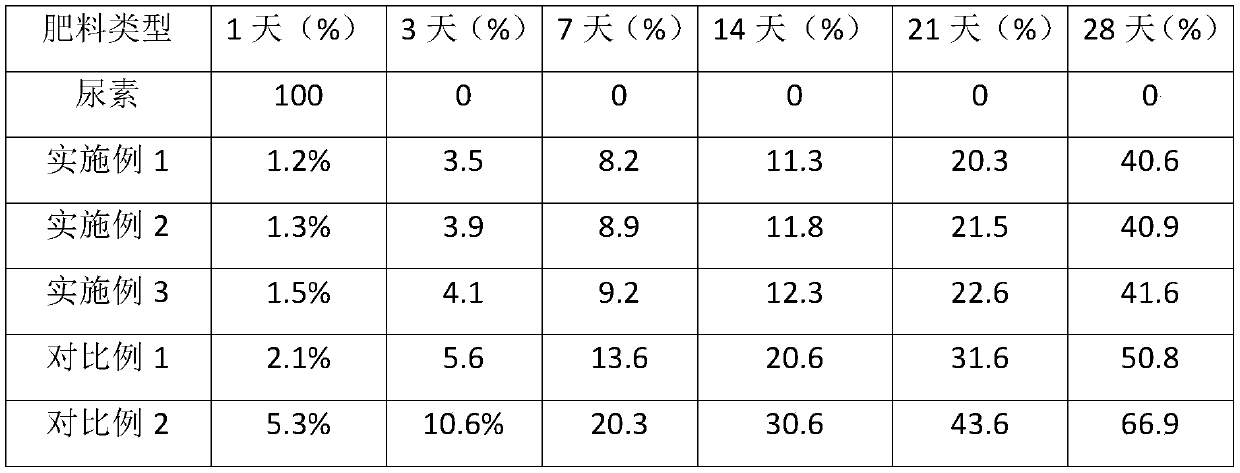

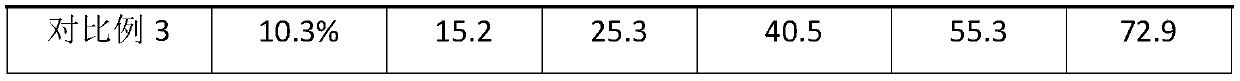

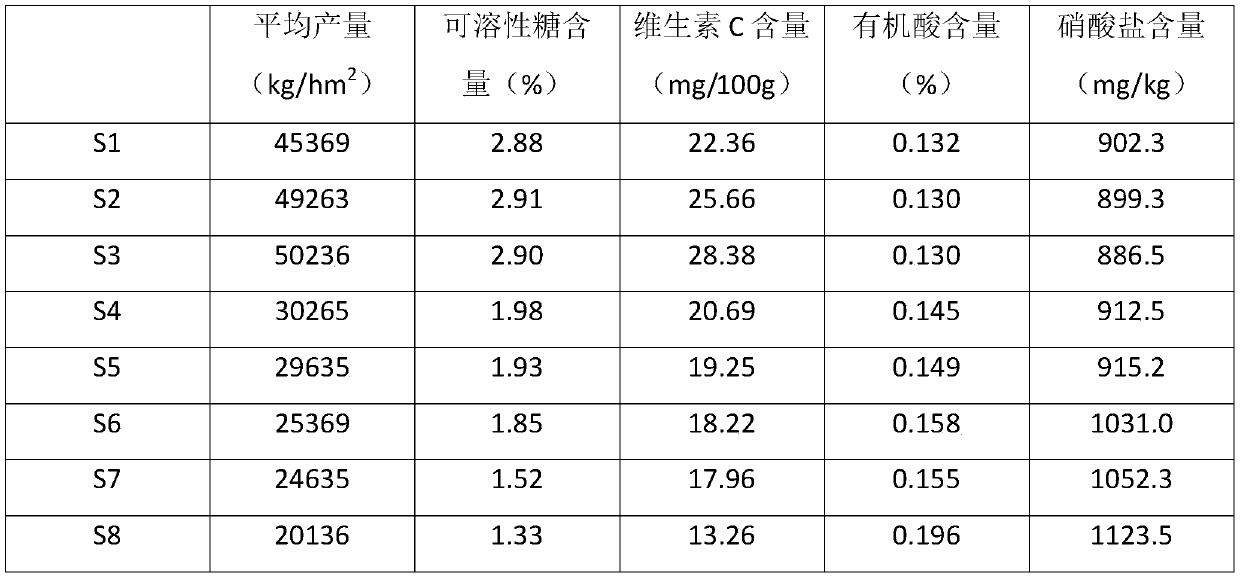

Slow release composite fertilizer for high-tower granulation and preparation method thereof

InactiveCN109776221AImprove disease resistancePromote crop growthClimate change adaptationAgriculture gas emission reductionPolyvinyl alcoholPhosphate

The invention discloses a slow release composite fertilizer for high-tower granulation and a preparation method thereof and belongs to the technical field of fertilizer. The fertilizer is prepared from, by weight, 100-150 parts of urea, 80-100 parts of monoammonium phosphate, 60-80 parts of potassium chloride, 20-40 parts of celestite powder, 10-20 parts of attapulgite powder, 10-20 parts of kieselguhr, 5-15 parts of a medium trace element mixture, 3-5 parts of a synergist and 5-10 parts of an outer-layer coating agent; the outer-layer coating agent is prepared in the mode that polyvinyl alcohol and polyvinylpyrrolidone are subjected to copolymerization, and then biomass charcoal is added. According to the slow release composite fertilizer, nanosilicon dioxide is added as the synergist, and through cooperation of the synergist and a coating material, an obvious slow release effect of the fertilizer is achieved. The prepared fertilizer is safe, environmentally friendly, has an obvious fertilizer efficiency, capable of achieving high tower granulation, low in cost and high in efficiency and has high market application potential.

Owner:GARSONI FERTILIZER MEISHAN

Noodles stirring device and noodles cooker

PendingCN107411534AWon't hurtEasy to useCooking insertsCooking vessel constructionsThermodynamicsProcess engineering

The invention provides a noodles stirring device and a noodles cooker and belongs to the technical field of food processing. The noodles stirring device comprises: a pot having a first receiving cavity for boiling noodles; a filter box having a second receiving cavity communicated with the first receiving cavity; a stirring and water outgoing pipe connected with the pot and including a water incoming end and a water outgoing end communicated with each other, wherein the water outgoing end is positioned in the first receiving cavity; a pump for pumping a liquid in the second receiving cavity to the water incoming end. Boiling water in the pot can be discharged from the water outgoing end through the filter box, the pump and the mixing and water outgoing pipe; the boiling water sprayed from the water outgoing end can stir the boiling water in the pot under the pressurizing action of the pump; the whole process has no need for manual stirring, natural spraying of the water never causes damage to noodles, and the service effect is good. The noodles stirring device has reasonable structural design and great market application potential. The noodles cooker comprises the noodles stirring device and has all functions of the noodles stirring device.

Owner:孟建彬

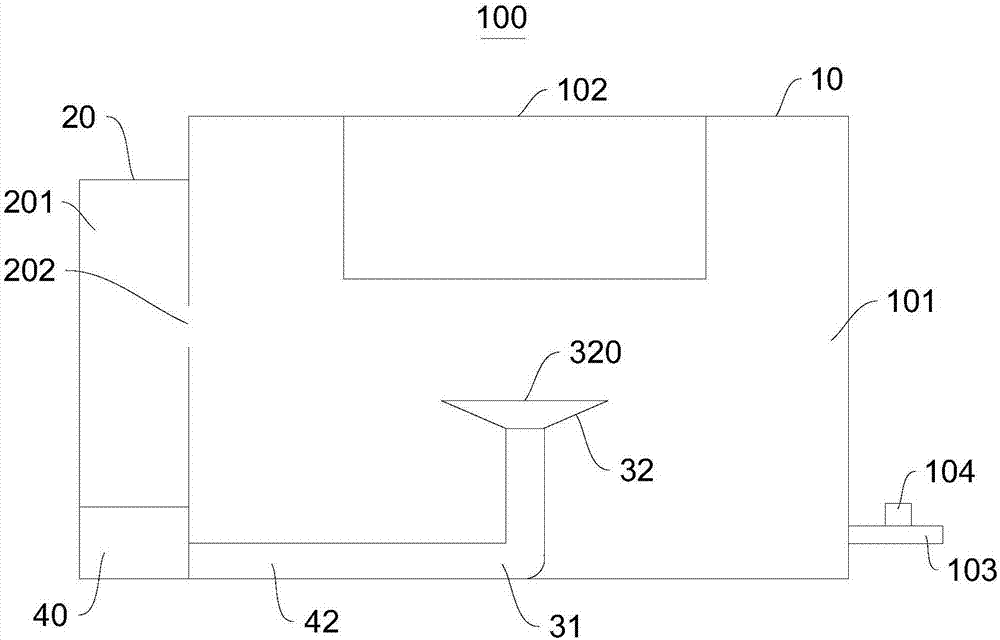

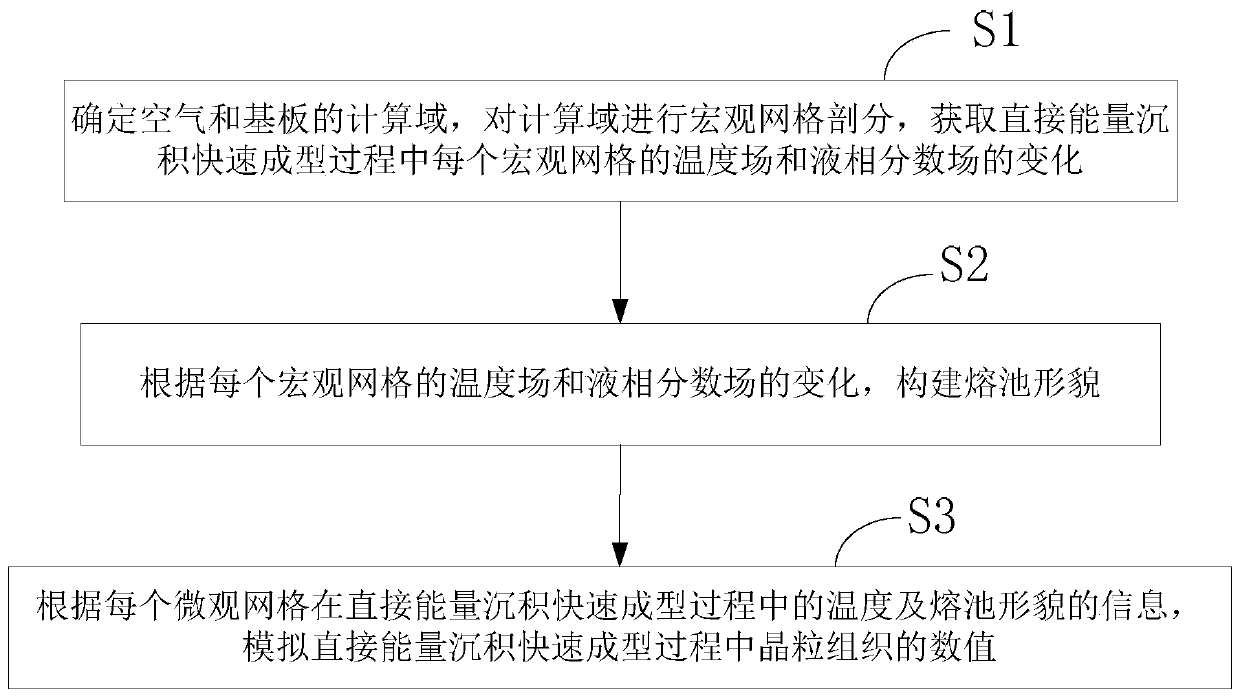

Grain structure numerical prediction method in metal rapid prototyping process

ActiveCN111036909AAccurate predictionSolve the large amount of calculationAdditive manufacturing apparatusIncreasing energy efficiencyMacroscopic scaleGrain structure

The invention discloses a grain structure numerical prediction method in a metal rapid prototyping process, solves a problem of large calculation amount during grain structure simulation in an energydeposition rapid prototyping process in the prior art and belongs to the technical field of rapid metal prototyping. The method comprises steps of S1, determining a computational domain of the air anda substrate, and carrying out macroscopic mesh generation of the computational domain to obtain changes of a temperature field and a liquid phase fraction field of each macroscopic mesh in a direct energy deposition rapid prototyping process; S2, according to the obtained changes of the temperature field and the liquid phase fraction field, dividing each macroscopic grid into a plurality of microcosmic grids, constructing the morphology of a molten pool, specifically, the information of the morphology comprises the number of crystalline grains of the non-molten part of a substrate, whether the microcosmic grids are molten or not in the direct energy deposition rapid prototyping process, epitaxial growth and the number of epitaxial growth cores; and S3, simulating the numerical value of the grain structure in the direct energy deposition rapid prototyping process according to the temperature of each micro grid in the direct energy deposition rapid prototyping process and the information of the morphology of the molten pool.

Owner:HARBIN UNIV OF SCI & TECH

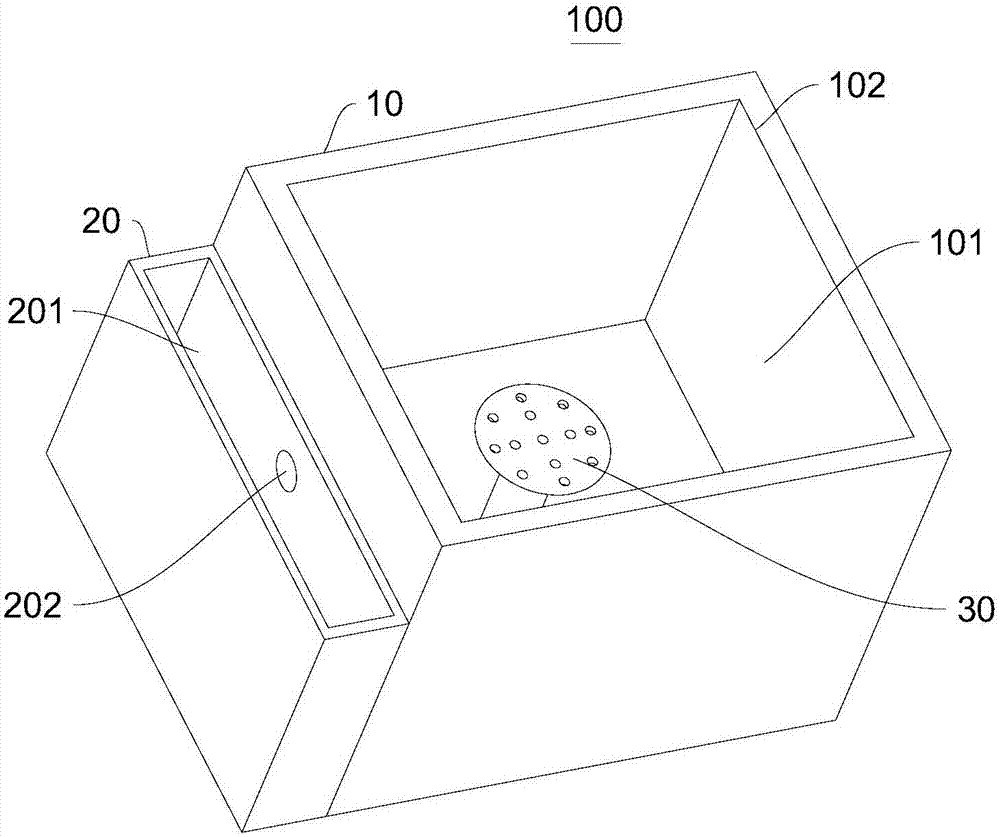

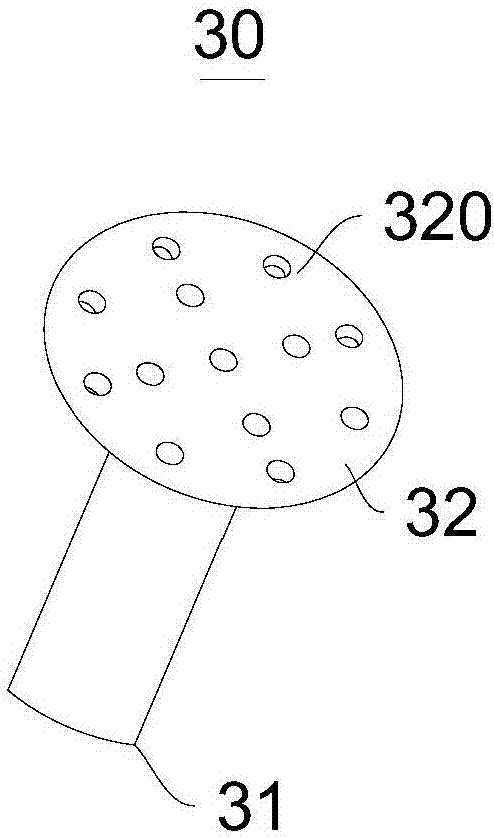

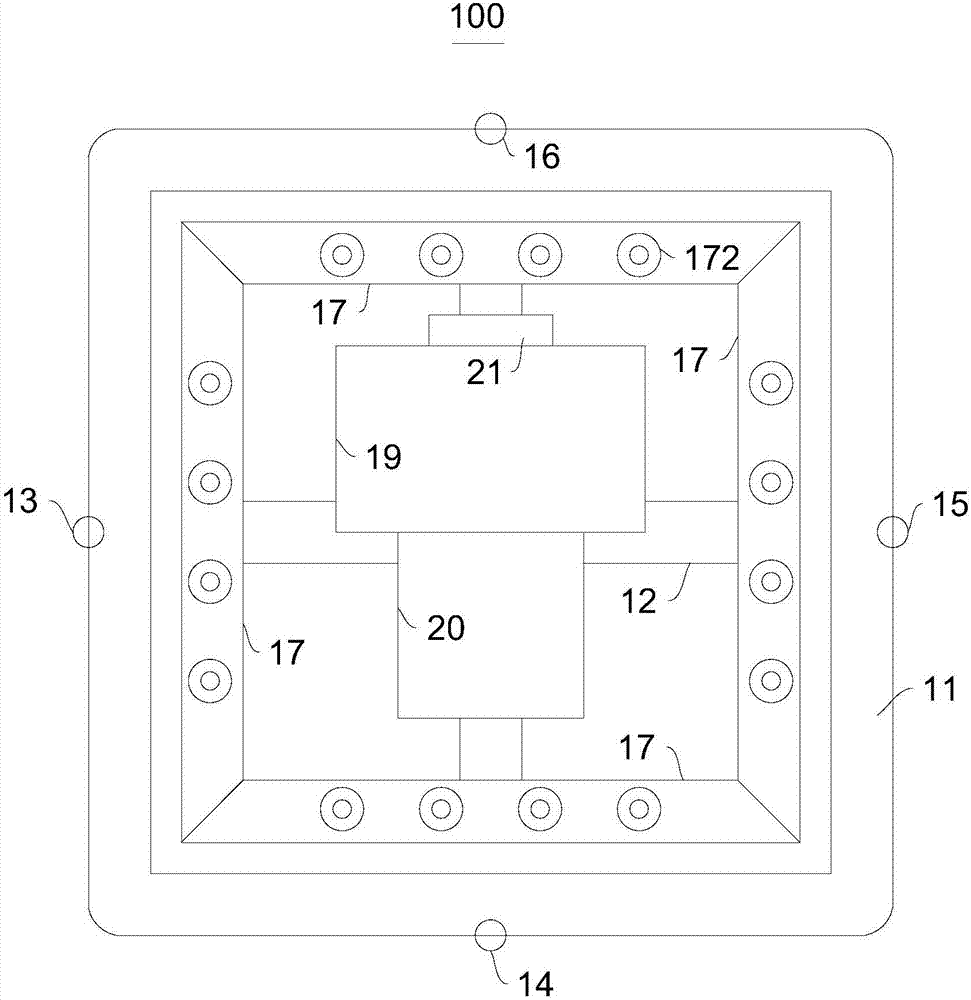

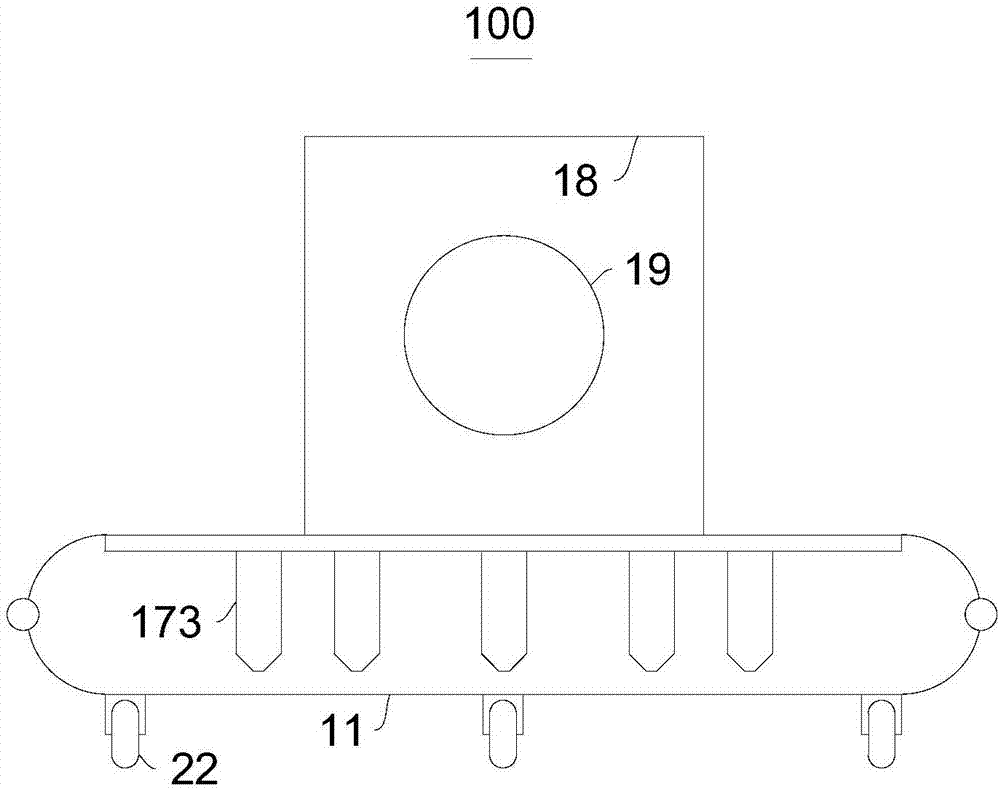

Lotus root digging machine and lotus root digging method

ActiveCN107873223AReasonable designHuge market application potentialDigger harvestersSpray nozzleEngineering

The invention provides a lotus root digging machine and a lotus root digging method, and belongs to the technical field of lotus root digging equipment. The lotus root digging machine includes a floatbarrel, a frame, a sensor assembly, working pipelines, a direction switching assembly and a lotus root digging assembly. The float barrel is of a square shape. The frame is connected to the float barrel. The sensor assembly includes a first sensor, a second sensor, a third sensor and a fourth sensor. The first sensor, the second sensor, the third sensor and the fourth sensor are sequentially disposed on the four sides of the float barrel, the working pipelines are connected to the frame, the four working pipelines correspond to the four sides of the float barrel and are provided with accommodating cavities, and the bottoms of the working pipelines are provided with a plurality of nozzles communicated with the accommodating cavities. The lotus root digging machine can automatically dig lotus roots, greatly reduces the labor strength, greatly reduces the cost of digging the lotus roots, and is suitable for large-scale planting in a lotus root field. The lotus root digging machine is designed rationally and has a great market potential. Through the lotus root digging method, efficient and high-quality digging work of the lotus roots can be achieved.

Owner:HEZHOU UNIV

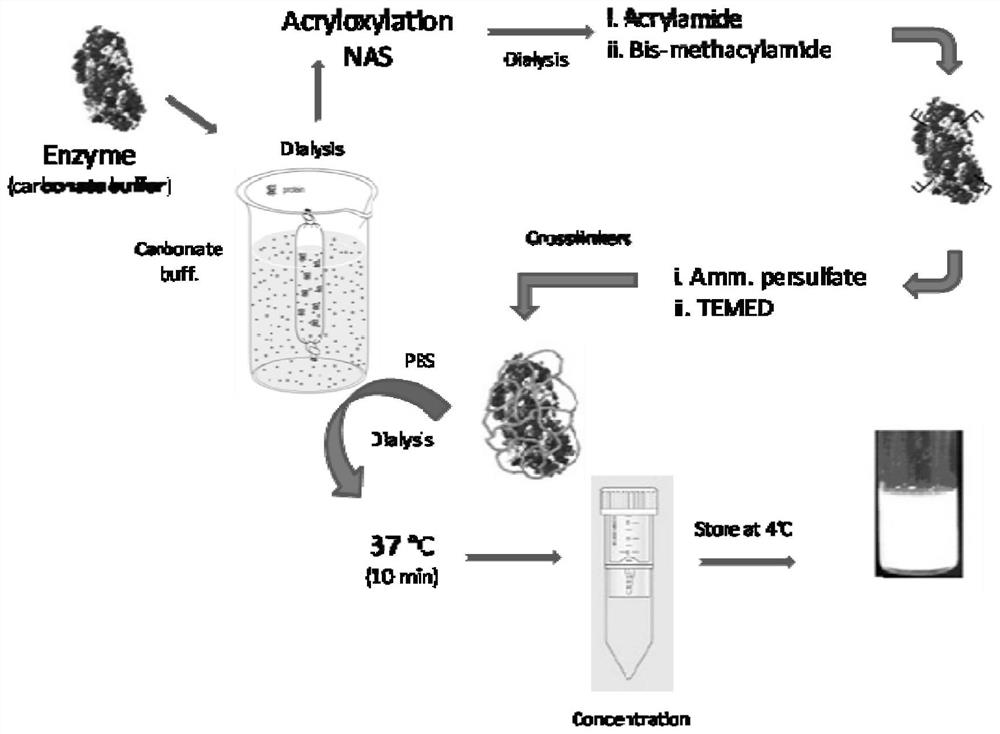

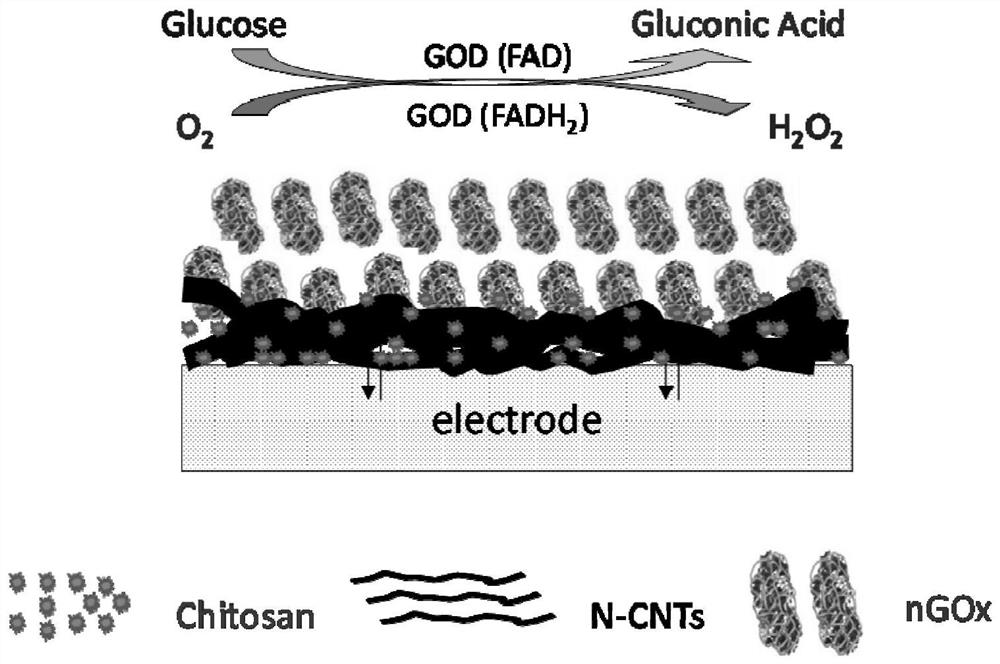

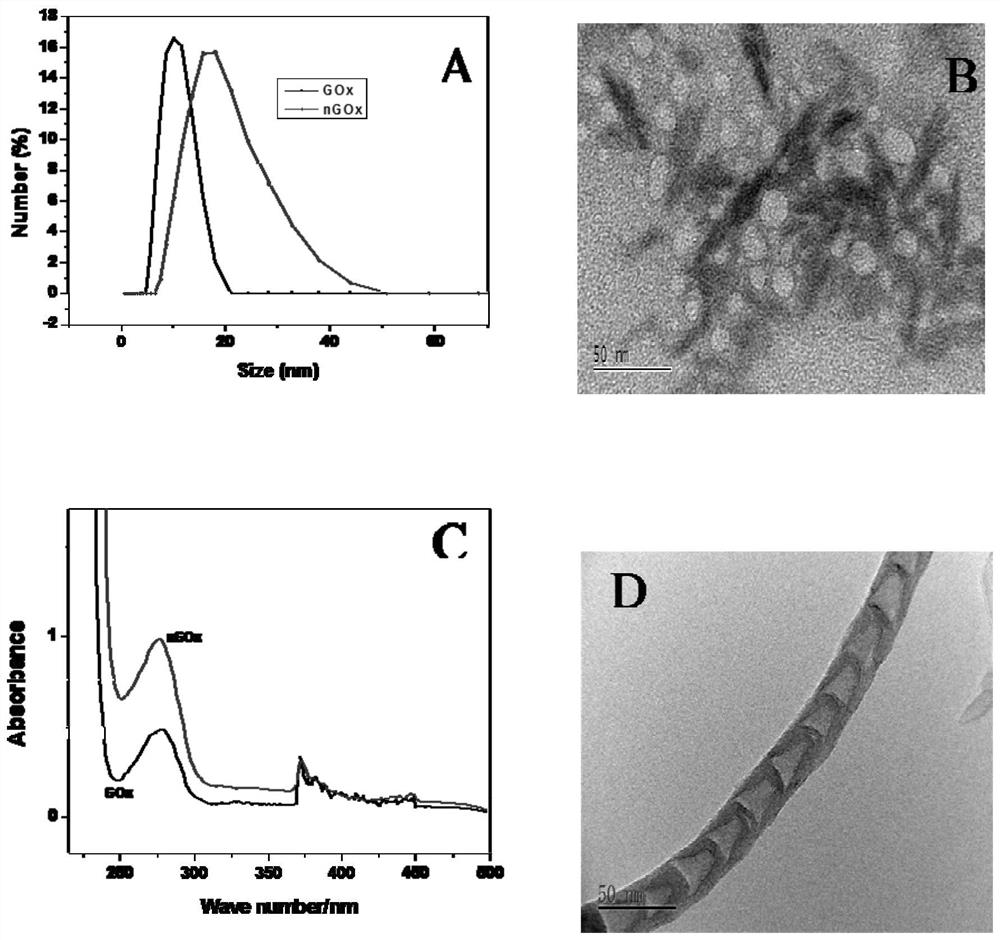

Glucose oxidase nanocapsule sensor and preparation and application thereof

ActiveCN111624244AImprove adaptabilityImprove toleranceMaterial analysis by electric/magnetic meansDiagnostic recording/measuringOxidative enzymeBiology

The invention discloses a glucose oxidase nanocapsule sensor and preparation and application thereof. An enzyme-based biosensor has a wide application prospect in the fields of biomedical treatment, life health, food safety, environmental safety, food fermentation and the like, and the main factor for limiting commercialization of the enzyme-based biosensor at present is that the stability of theenzyme sensor needs to be further improved. The invention provides a preparation method and application of a high-stability enzyme sensor, namely a method for preparing the enzyme sensor based on an enzyme molecule nanocapsule. The preparation method of the enzyme nanocapsule sensor mainly comprises the following steps: firstly, preparing an enzyme monomolecular nanocapsule (or an enzyme polymolecular nanocapsule) by using an in-situ free radical polymerization method; and then, using the enzyme molecule nanocapsule to prepare the enzyme nanocapsule sensor. The enzyme sensor has the advantagesthat the thermal stability, the organic solvent tolerance, the storage life, the service life and the like of the enzyme sensor are obviously improved. The enzyme nanocapsule sensor obtained by the invention has huge market application potential in the fields of human body wearable equipment, biomedical treatment, analysis and detection, food fermentation and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

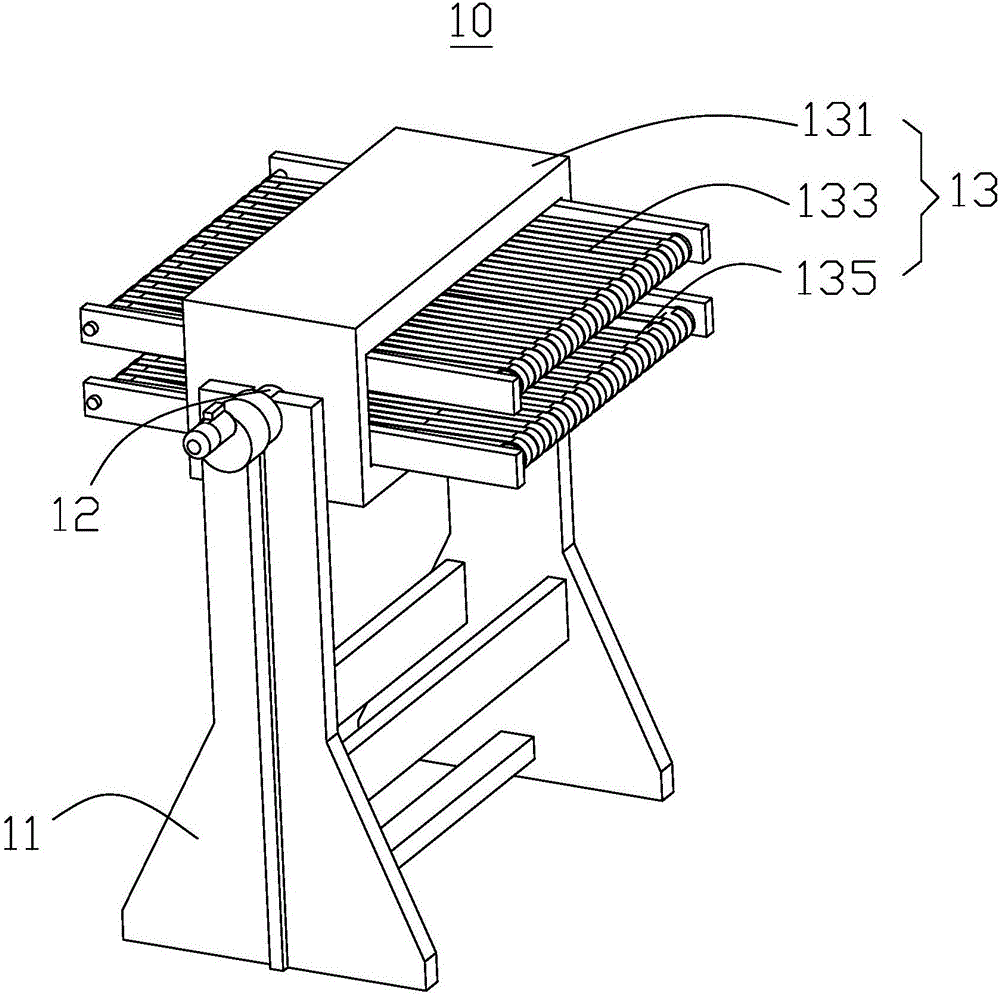

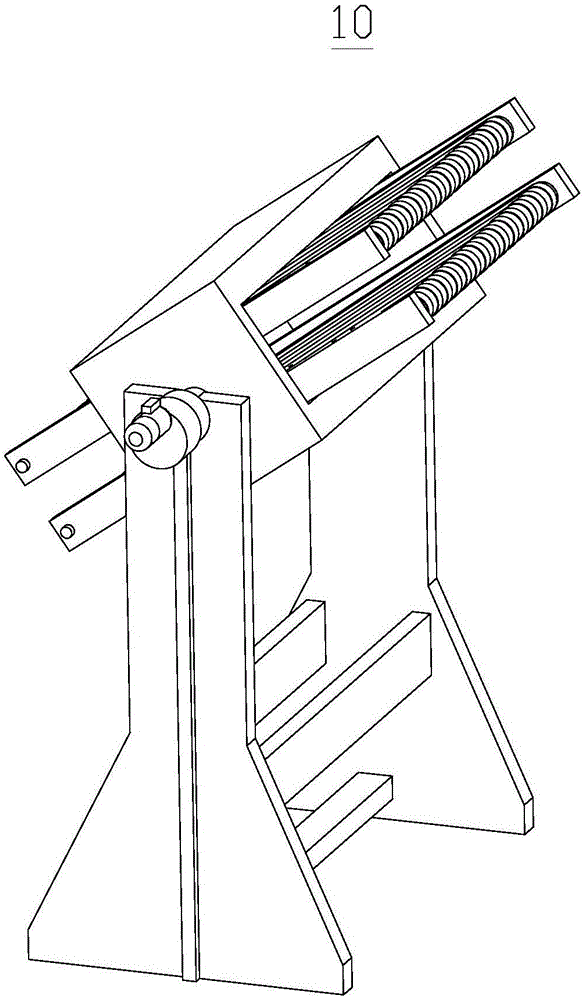

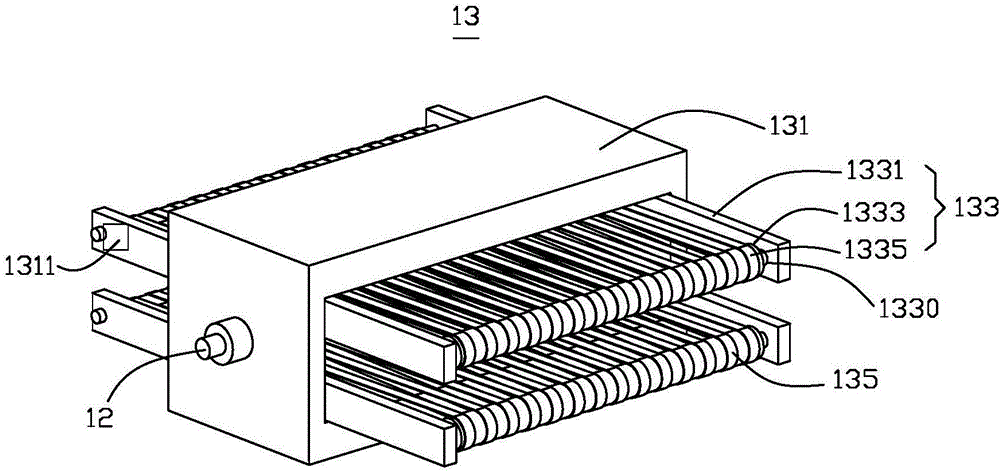

Corrugated paper board overturning machine and full-automatic corrugated paper board overturning and staggered-stacking machine

The invention provides a corrugated paper board overturning machine and a full-automatic corrugated paper board overturning and staggered-stacking machine, and belongs to the technical field of corrugated paper board production equipment. The corrugated paper board overturning machine comprises a machine frame and an overturning assembly; the overturning assembly comprises an overturning body and two conveying parts; the overturning body is rotatably connected to the machine frame around a first rotating shaft; and the two conveying parts are slidably connected to the overturning body in the radial direction of the first rotating shaft, can get close to or keep far away from each other, are oppositely arranged and form a conveying channel suitable for conveying corrugated paper boards. The corrugated paper board overturning machine has the function of automatically overturning the corrugated paper boards, manual overturning is not needed in the whole process, the efficiency is high, due to the overturning function of the corrugated paper board overturning machine, the overturning effect is good, and the overall use effect is good. The full-automatic corrugated paper board overturning and staggered-stacking machine comprises the corrugated paper board overturning machine and has all the functions of the corrugated paper board overturning machine.

Owner:焦作市科特制辊有限公司

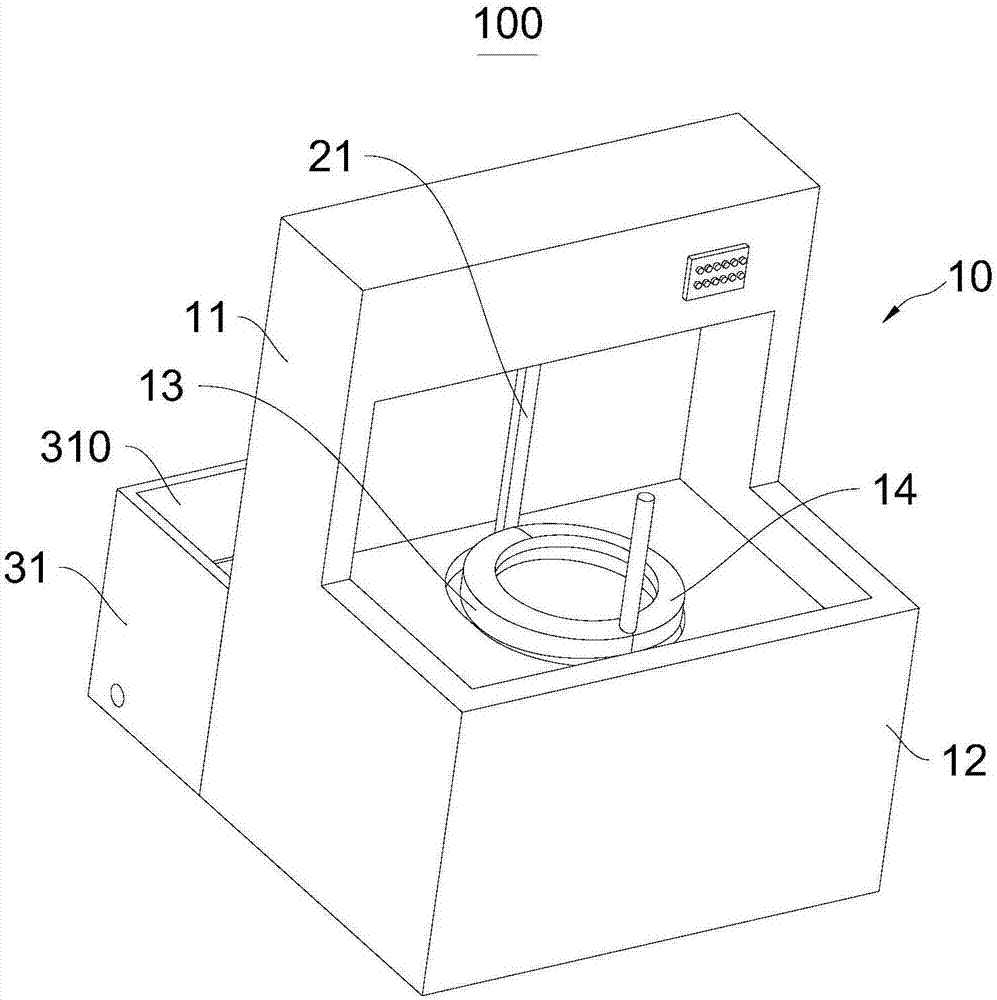

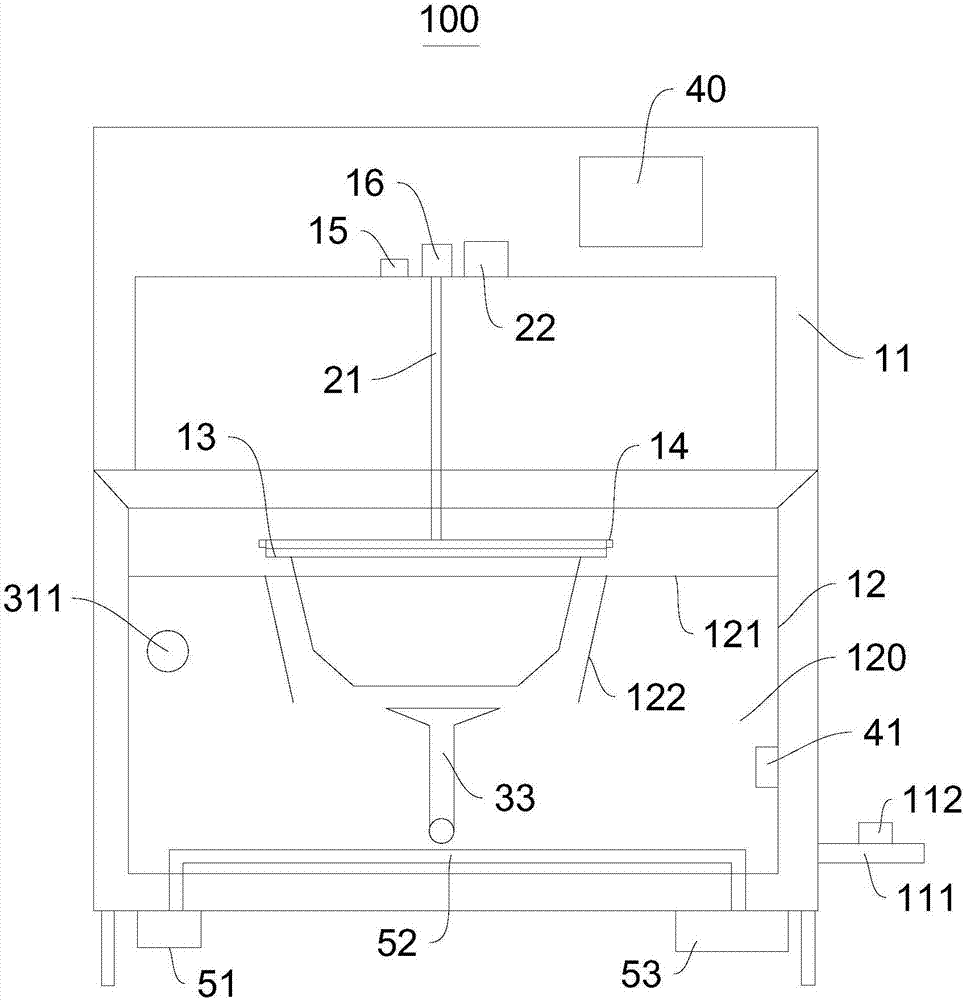

Centrifugal washing equipment and centrifugal washing method

ActiveCN108034566AReduce labor intensityLow input costBioreactor/fermenter combinationsBiological substance pretreatmentsMechanical engineeringCentrifuge

The invention provides centrifugal washing equipment and a centrifugal washing method, and belongs to the technical field of microorganism centrifugal washing. The centrifugal washing equipment comprises a rack, a first sliding part, a first driving part, a second sliding part, a second driving part, a connecting part, a mechanical clamping hand, a third driving part, a centrifugal machine, a waste liquid pouring device, an injecting device, a vibration table and a control device, wherein the first sliding part is slidably connected to the rack along a first axis; the first driving part is connected with the rack and is used for driving the first sliding part; the second sliding part is slidably connected to the first sliding part along a second axis; the first axis is horizontally arranged; the second axis is vertically arranged; the second driving part is connected with the first sliding part and is used for driving the second driving part. The centrifugal washing equipment can automatically complete the centrifugal washing process, so that the labor intensity is greatly reduced, the work efficiency is obviously improved, and the centrifugal washing equipment is simple in structure, reasonable in design, relatively low in investment cost, high in practicability and huge in market application potential.

Owner:广州承葛生物科技有限公司 +1

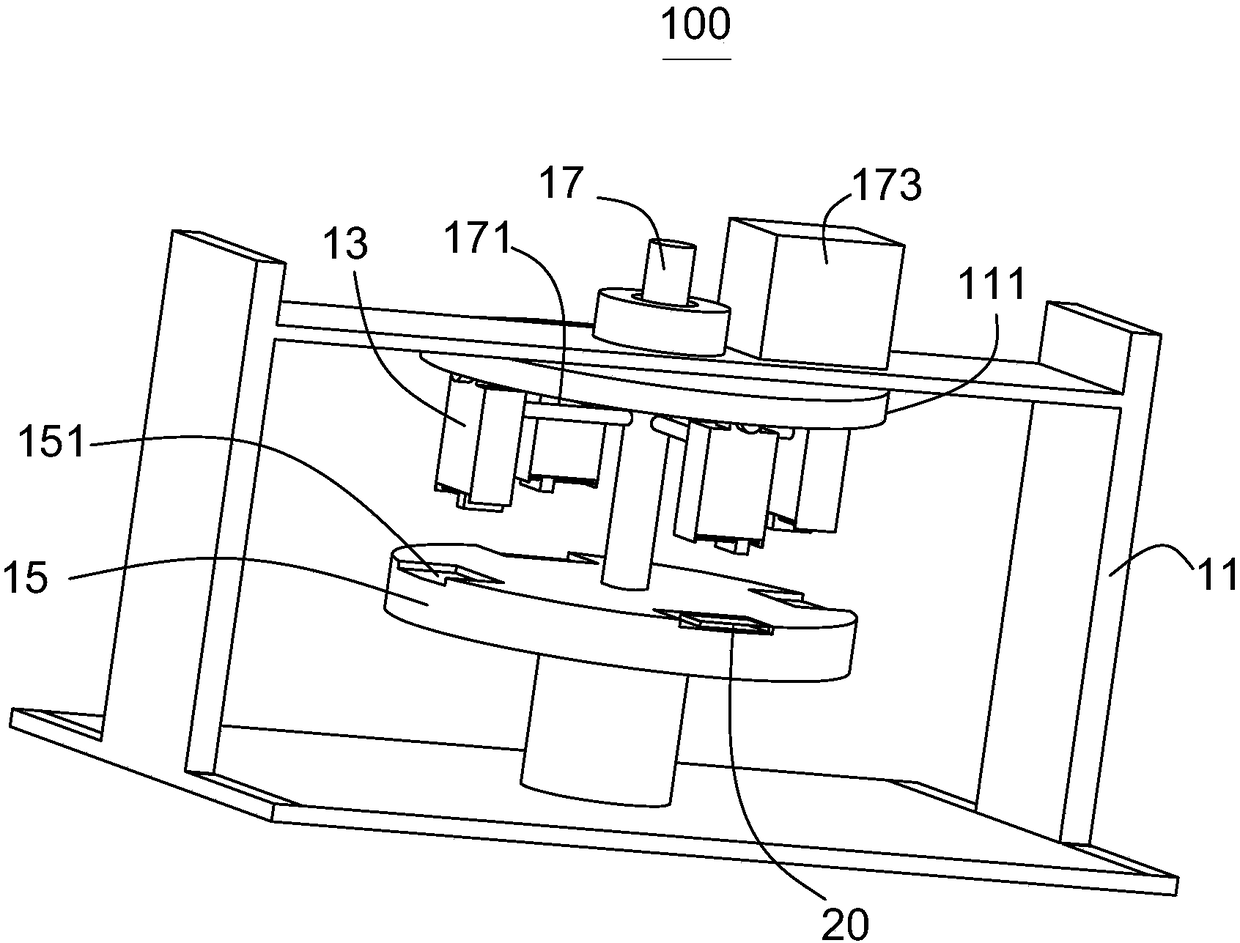

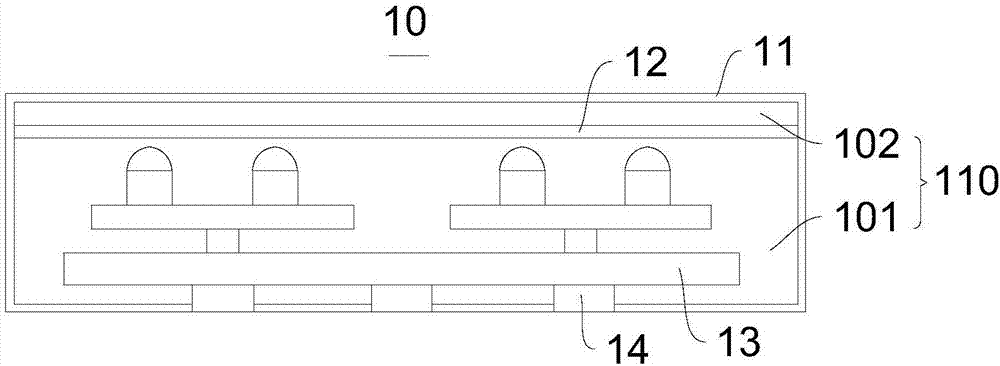

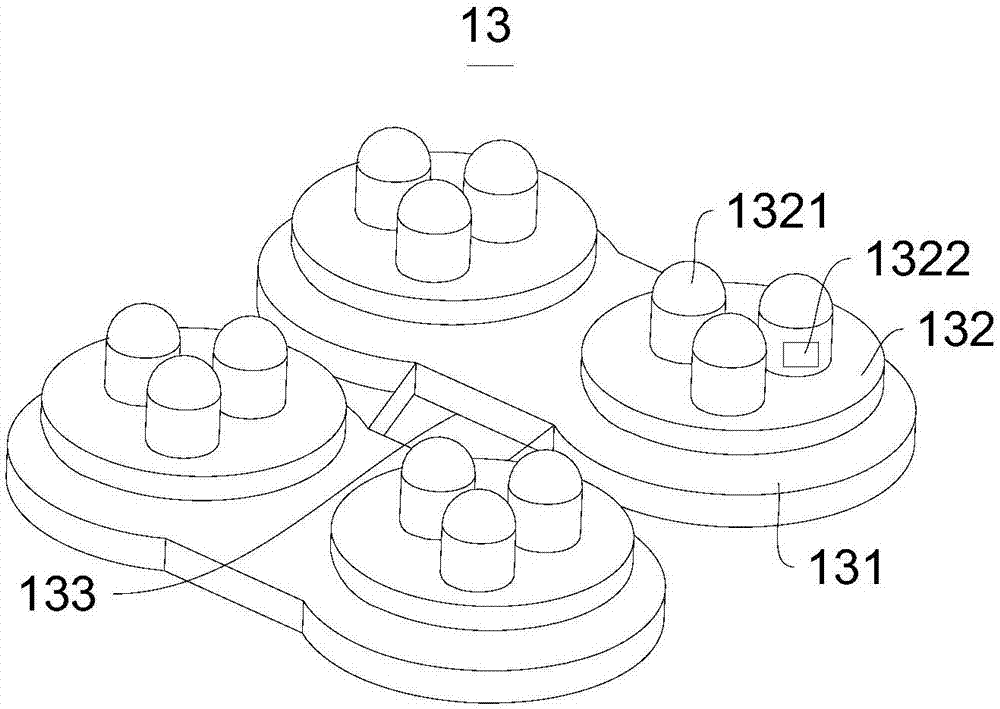

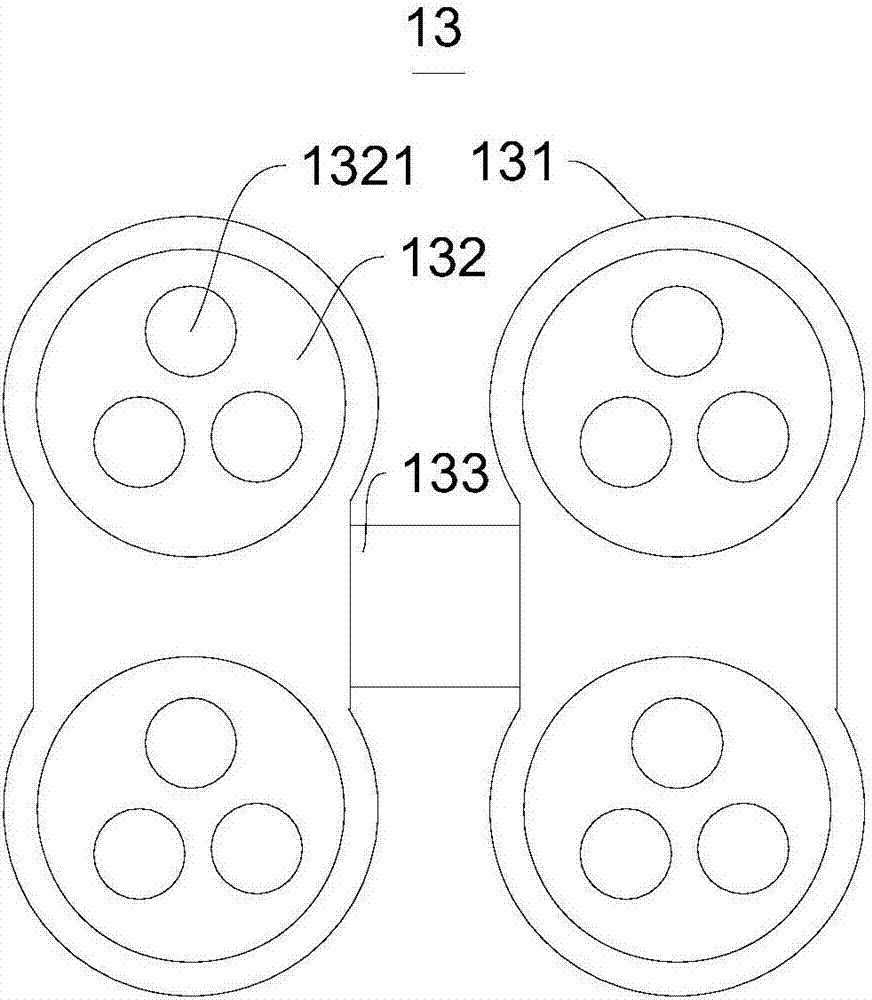

A jet printing machine and printed circuit board jet printing system

ActiveCN106739501BCyclicalImprove work efficiencyTypewritersMechanical engineeringPrinted circuit board

The invention provides a jet printer and a printed circuit board jet printing system, belonging to the technical field of jet printing. The jet printing machine includes a base, a nozzle assembly and a work turntable, the number of the nozzle assembly is at least three and is used for inkjet printing on a printed circuit board, and the nozzle assembly and the work turntable are synchronously rotatably connected to the base The nozzle assembly is slidably connected to the base along the axial direction of the rotating shaft. The side of the working turntable close to the nozzle assembly is provided with an embedding groove corresponding to the nozzle assembly. The embedding groove is used for embedding printed circuit boards. The nozzle assembly The embedding groove can be approached or separated from in the axial direction of the rotating shaft. Each nozzle assembly processes the corresponding printed circuit board. The overall process is cyclical and does not require too many human resources. The work efficiency is greatly improved and the use effect is better. The printed circuit board inkjet printing system includes the above-mentioned inkjet printer, which has all the functions of the inkjet printer.

Owner:盐城天锐先锋电子科技有限公司

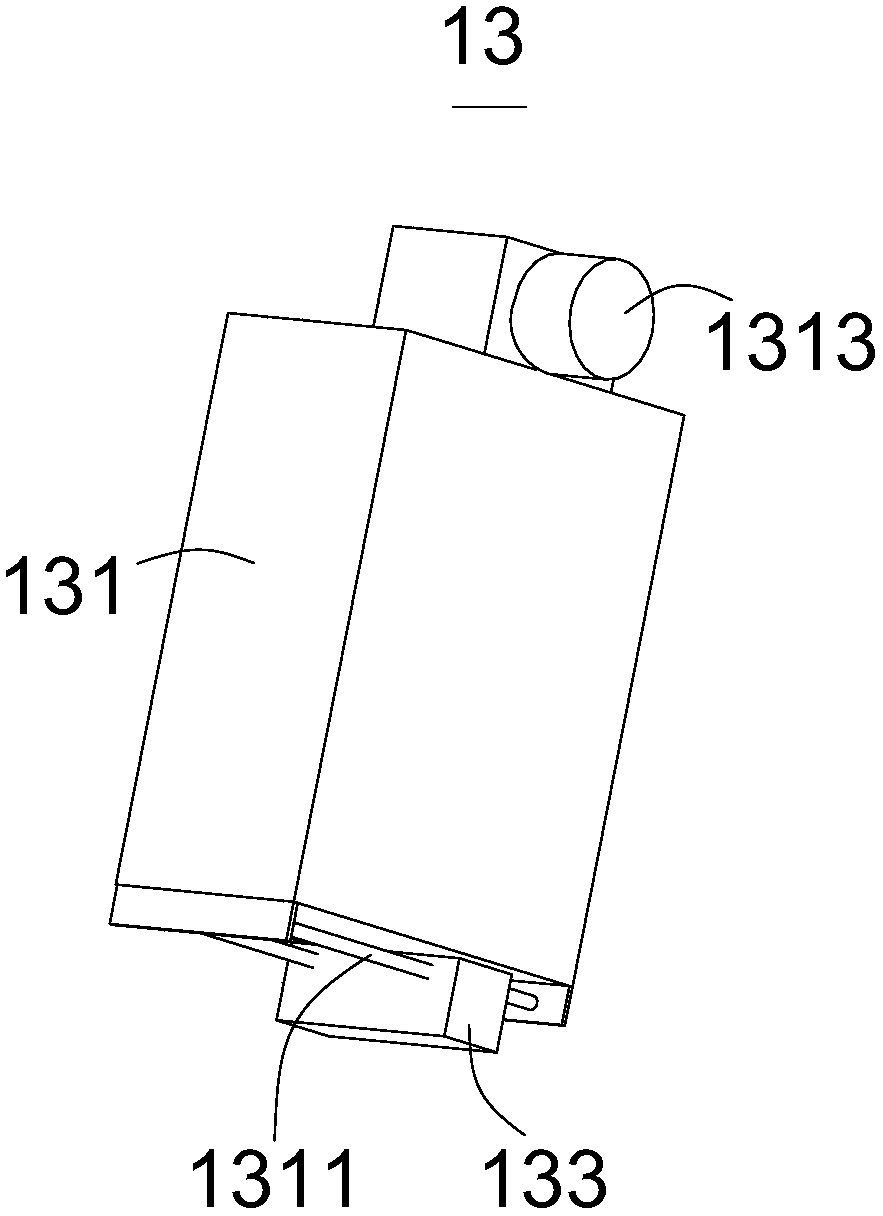

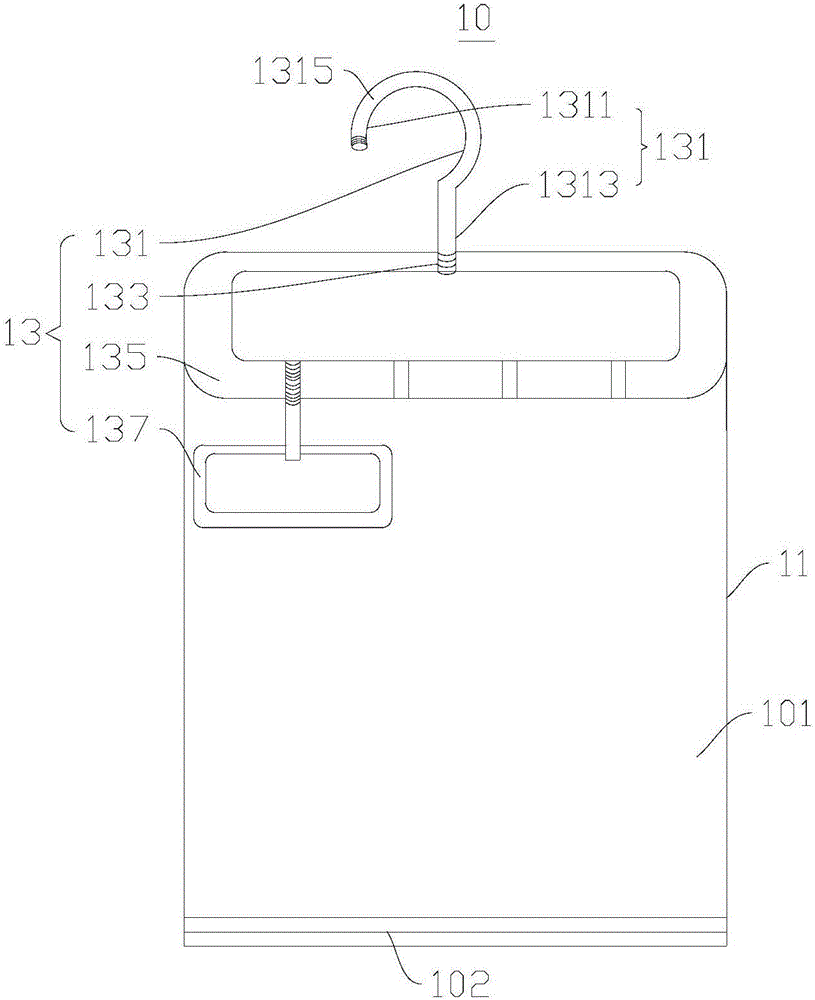

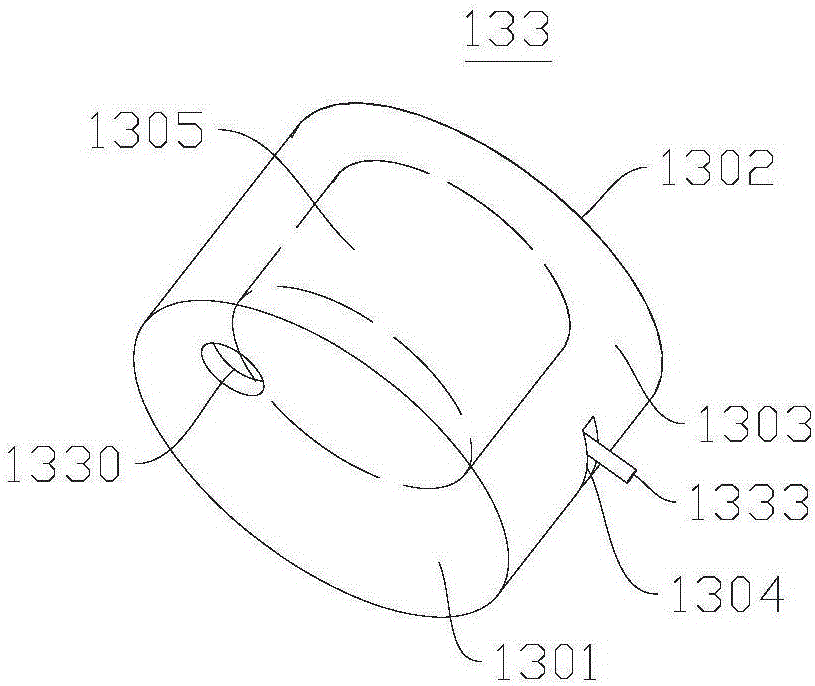

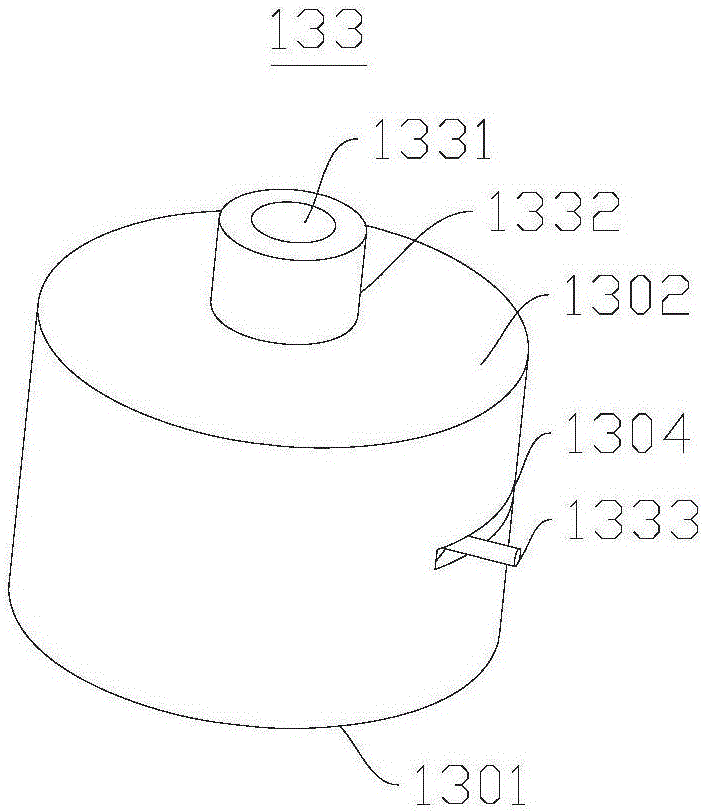

Vacuum bag and vacuum containing system

InactiveCN106809521AQuick tidy upCompact structureGarmentsPackaging under vacuum/special atmosphereEngineeringClothes hanger

The invention provides a vacuum bag and a vacuum containing system, and belongs to the technical field of vacuum storage. The vacuum bag comprises a bag body and a hanging assembly. The bag body is provided with a containing cavity used for containing clothes. The hanging assembly comprises a fixed piece, a connecting piece and a plurality of clothes hanger pieces for hanging the clothes. The fixed piece is in fixed and sealed connection with the bag body and is used for enabling the containing cavity to communicate with the outer portion of the bag body. The connecting piece is located in the containing cavity and detachably connected to the fixed piece. The clothes hanger pieces are located in the containing cavity and detachably connected to the connecting piece. The fixed piece is provided with an air exhaust cavity used for air exhaust. A vent hole is formed in the side, close to the containing cavity, of the fixed piece. The vacuum bag is simple and compact in structure, good in sealing effect, good in overall use effect and huge in market utilization potentiality. The vacuum containing system comprises the above vacuum bag and has all the functions of the vacuum bag.

Owner:YANCHENG INST OF TECH

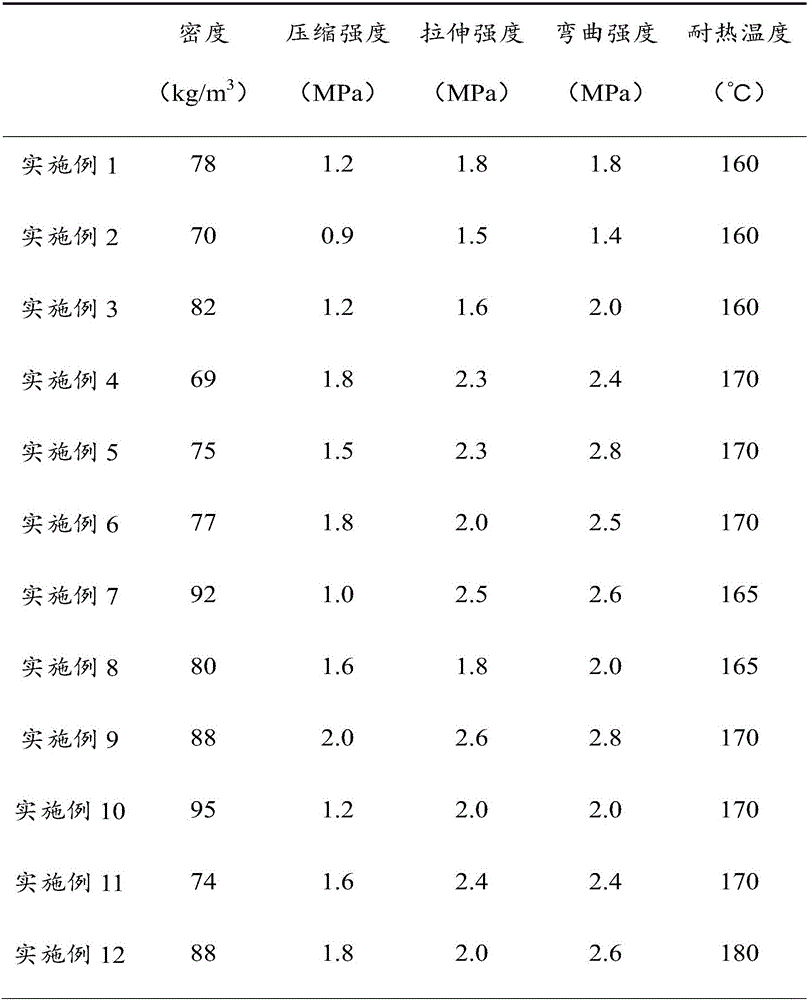

Polymethacrylimide foam plastic and preparation method thereof

InactiveCN106632831AImprove the defects of easy deformation and discolorationImprove rigidityFoaming agentPolymer science

The invention relates to polymethacrylimide foam plastic and a preparation method thereof and belongs to the field of macromolecular materials. The polymethacrylimide foam plastic is prepared by mixing materials, polymerizing and foaming; the materials include, by weight, 30-150 parts of acrylonitrile, 20-150 parts of methacrylic acid, 0.1-6 parts of third monomer, 0.1-5 parts of nitrogen-substituted maleimide, 0.04-4 parts of azo-initiator, 0.04-8 parts of peroxy-initiator, 0.05-6 parts of a crosslinking agent, 0.8-25 parts of a foaming agent, 0.2-5 parts of a nucleating agent, 0.3-8 parts of a release agent, and 0.2-6 parts of an aid. The polymethacrylimide foam plastic has low cost and high cost performance, and may meet the requirement on the application of composite core materials from different processes and with different properties; in addition, the invention also relates to the preparation method of the polymethacrylimide foam plastic; the preparation method is simple, easy to perform, and good in effect.

Owner:湖南兆恒材料科技有限公司

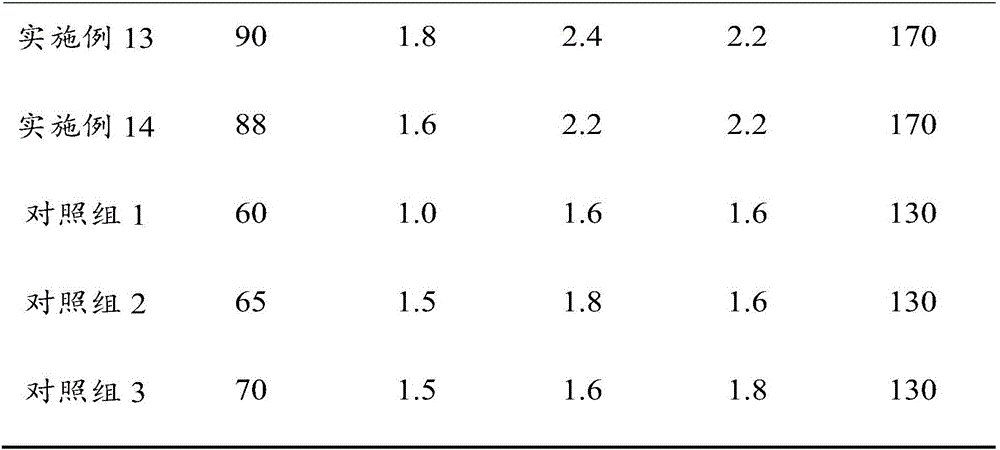

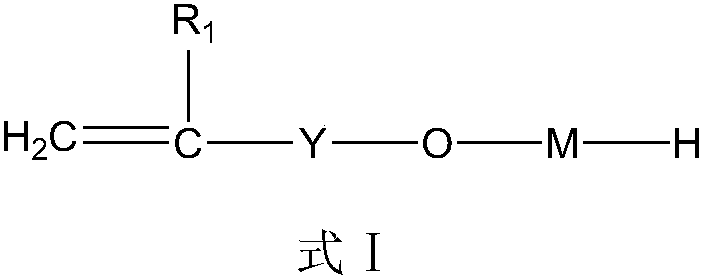

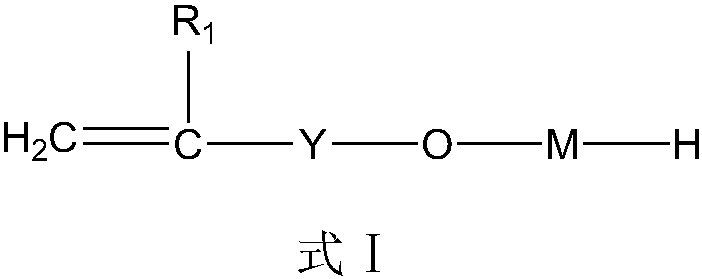

Viscosity reduction polycarboxylic acid water reducer and preparation method thereof

ActiveCN108264615ASignificant steric stabilization effectGood viscosity reductionPolymer scienceAcid water

The invention provides a viscosity reduction polycarboxylic acid water reducer and a preparation method thereof. The viscosity reduction polycarboxylic acid water reducer is a polymer taking unsaturated carboxylic acid, unsaturated polyalkoxylated ether and allyl or methyl allyl modified linear phenolic resin as co-monomers. The linear phenolic resin serving as the co-monomer is added into the viscosity reduction polycarboxylic acid water reducer, an aromatic nucleus structure can be introduced into the polycarboxylic acid water reducer, so that the adsorption efficiency and the adsorption thickness of cement particle surface polymer molecules can be effectively improved, the space stabilizing effect of the water reducer can be more remarkable, and the viscosity reduction polycarboxylic acid water reducer has obvious viscosity reduction effects and is simple in preparation method, strong in operability, low in energy consumption, low in cost and huge in market application potential.

Owner:LIAONING OXIRANCHEM INC

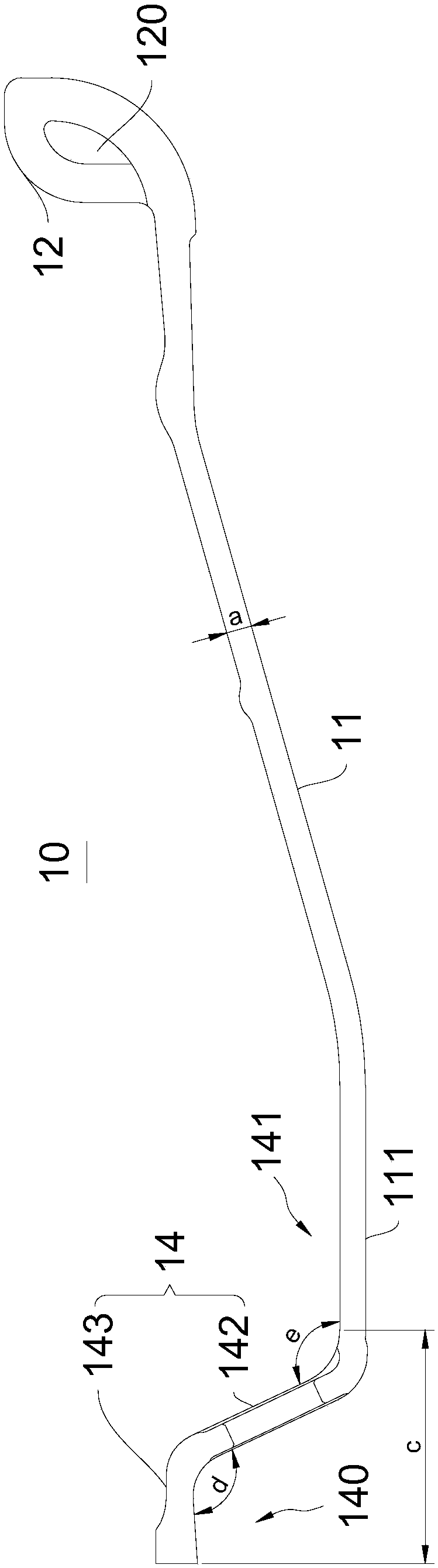

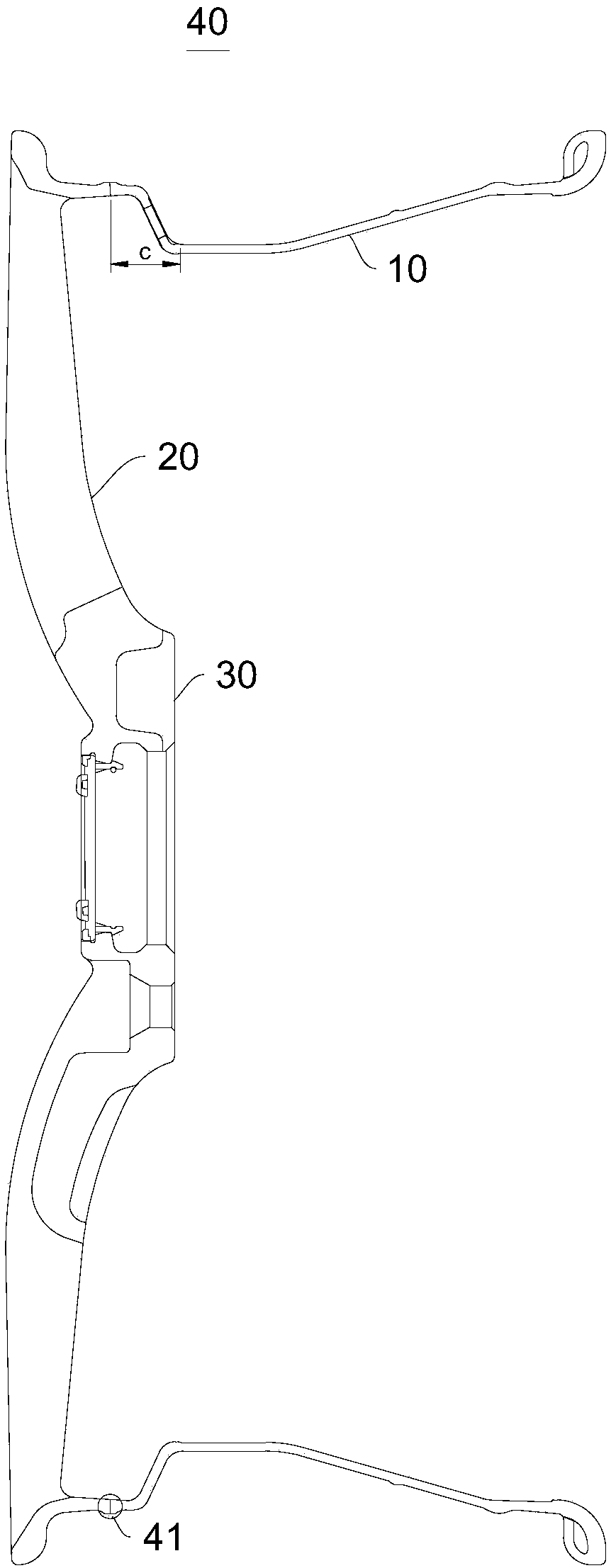

Stomach tube and nasal feeding device

The invention provides a stomach tube and a nasal feeding device, and belongs to the technical field of medical apparatus. The stomach tube includes a stomach tube body, the stomach tube body is provided with an entry end and an exit end for stretching into a gastral cavity, the outer side of the stomach tube body is arranged with an umbrella-shaped stopper and a first pressure sensor, the umbrella-shaped stopper includes an expansion portion and a connecting portion which is connected with the stomach tube body, the stomach tube body has a first state where the expansion portion is shrunk so that the gastral cavity can communicate with an esophagus, and the stomach tube body also has a second state where the expansion portion is expanded so that the gastral cavity can be separated from the esophagus. The stomach tube can receive pressure signals in the gastral cavity by the first pressure sensor to control the shrinkage or expansion of the expansion portion, and the reflux phenomenon is avoided. The stomach tube has a high comfort level when used, is reasonable in structural design and compact in mechanism, and has great potential in market application. The nasal feeding device includes the stomach tube and has all functions the stomach tube has.

Owner:THE AFFILIATED HOSPITAL OF SOUTHWEST MEDICAL UNIV

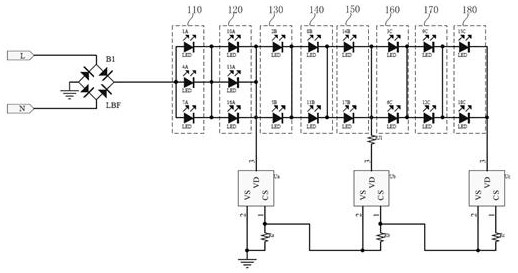

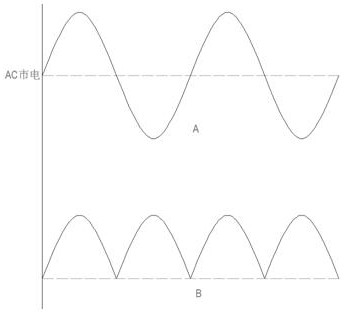

Silicon controlled rectifier adjusting circuit of high-voltage lamp strip

InactiveCN111615235AReduce installation difficultyIncrease brightnessElectrical apparatusSilicon-controlled rectifierFull bridge

The invention discloses a silicon controlled rectifier adjusting circuit of a high-voltage lamp strip. The silicon controlled rectifier adjusting circuit comprises a live wire input end, a zero line input end, a full-bridge rectification module, a first group of LED circuit modules, a second group of LED circuit modules, a third group of LED circuit modules, a first silicon controlled rectifier chip, a second silicon controlled rectifier chip and a third silicon controlled rectifier chip. The lamp strip comprises a plurality of minimum lamp strip units, the minimum lamp strip units are arranged in parallel, and each minimum lamp strip unit comprises the silicon controlled rectifier adjusting circuit of the high-voltage lamp strip in any embodiment. According to the silicon controlled rectifier adjusting circuit of the high-voltage lamp strip, the defects of the application of an existing LED lamp strip are overcome, an external large-size power supply is removed, and the LED lamp stripis directly connected to the mains supply for use, so that the LED lamp strip is free of driving, the installation difficulty is reduced, and the silicon controlled rectifier adjusting circuit of thehigh-voltage lamp strip can be well applied to a narrow space and is not limited by the size and power adaptation of the power supply. The silicon controlled rectifier adjusting circuit of the high-voltage lamp strip is compatible with the existing silicon controlled rectifier dimming circuits, and saves the application cost.

Owner:GUANGDONG MICROVIEW TECH CO LTD

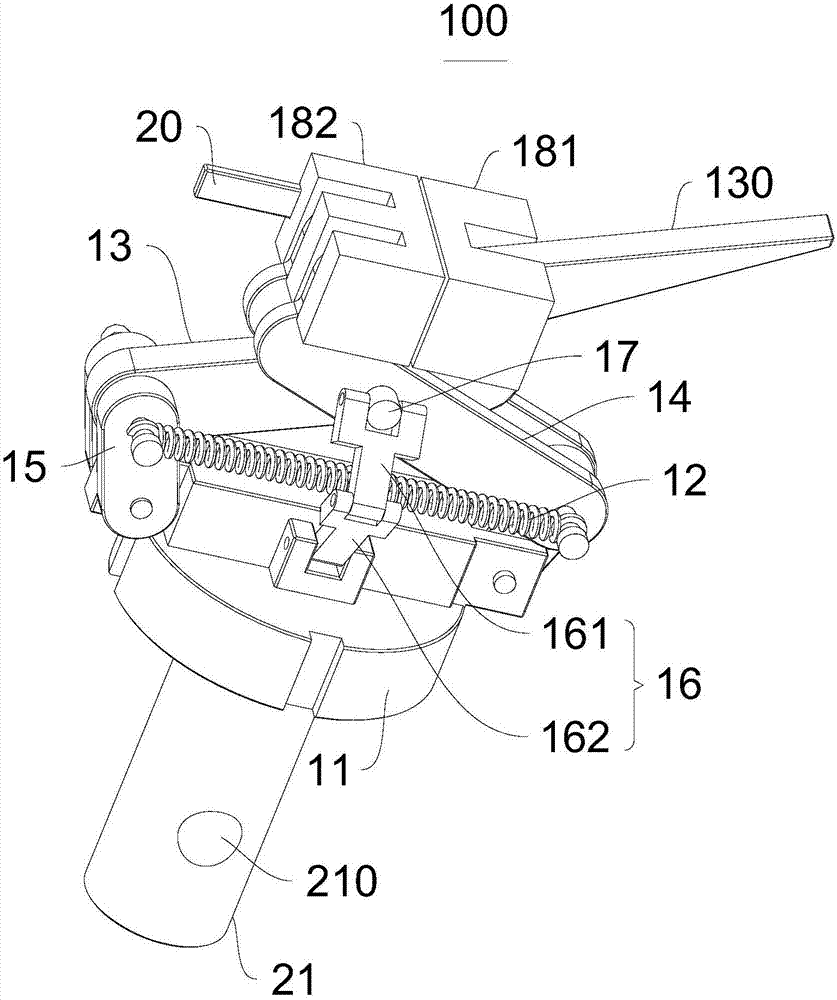

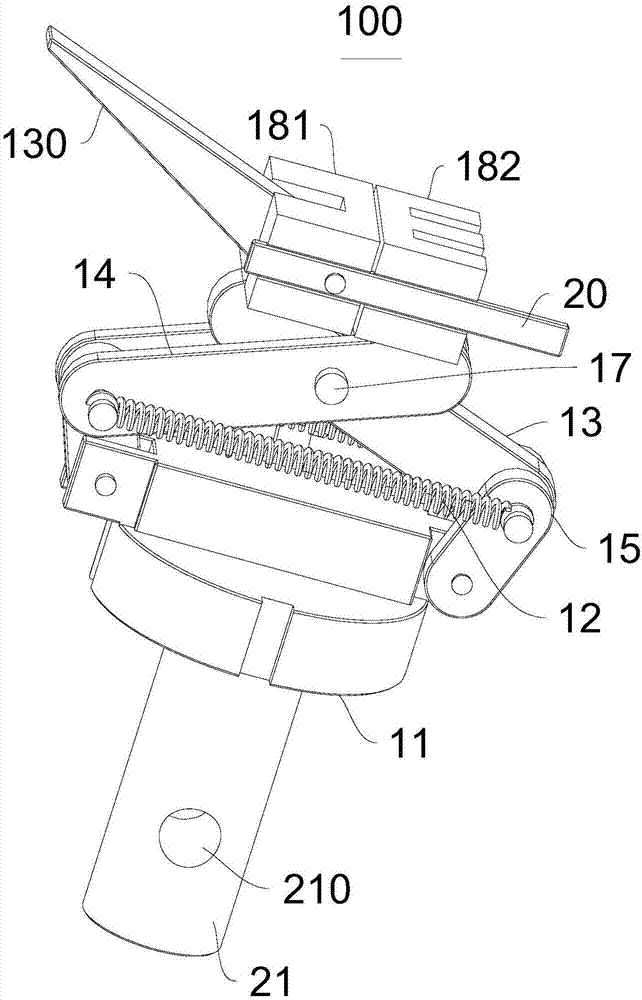

Clamp and clamping device

Owner:广东广铝铝型材有限公司

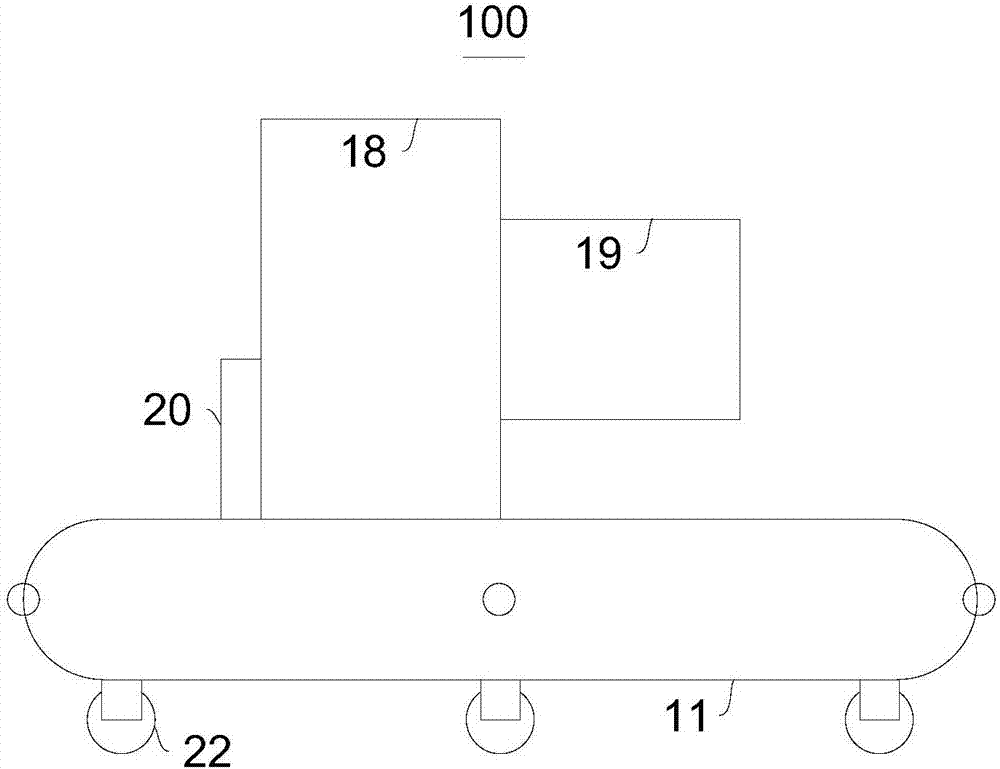

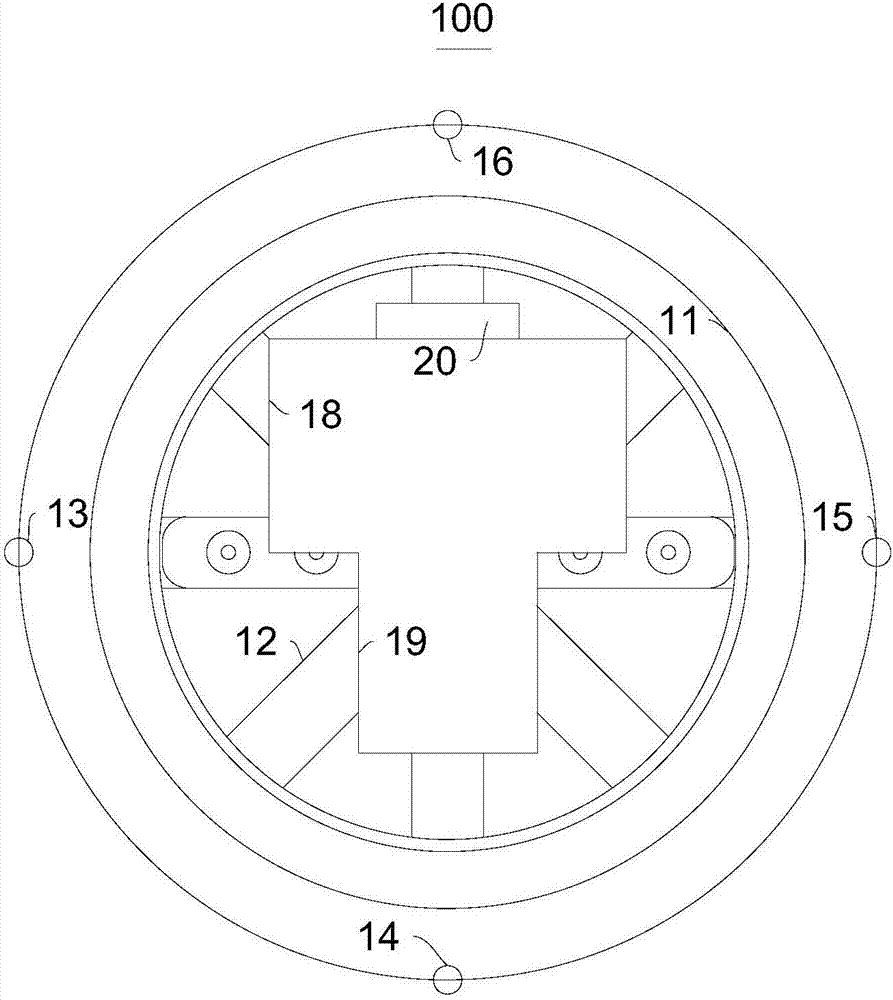

Lotus root digging machine and lotus root digging method

ActiveCN107873221AReasonable designHuge market application potentialDigger harvestersEngineeringUltimate tensile strength

The invention provides a lotus root digging machine and a lotus root digging method, and belongs to the technical field of lotus root digging equipment. The lotus root digging machine includes a floatbarrel, a frame, a sensor assembly, a working pipeline, a drive member and a lotus root digging assembly. The float barrel is of a round shape. The frame is connected to the float barrel. The sensorassembly includes a first sensor, a second sensor, a third sensor and a fourth sensor. The first sensor, the second sensor, the third sensor and the fourth sensor are evenly disposed on the sides of the float barrel, the working pipeline is provided with an accommodating cavity, a rotating part is arranged in the middle of the working pipeline, the rotating part is rotatably connected to the frame, and the bottom of the working pipeline is provided with a plurality of nozzles communicated with the accommodating cavity. The lotus root digging machine can automatically dig lotus roots, greatly reduces the labor strength, greatly reduces the cost of digging the lotus roots, and is suitable for large-scale planting in a lotus root field. The lotus root digging machine is designed rationally and has a great market potential. Through the lotus root digging method, efficient and high-quality digging work of the lotus roots can be achieved.

Owner:HEZHOU UNIV

Massager and foot bath bucket

PendingCN107049759APlay the role of massageAvoid direct contactDevices for pressing relfex pointsBathing devicesHuman bodyEngineering

The invention provides a massager and a foot bath bucket and belongs to the technical field of health products. The massager comprises a housing, an isolation layer and a massage device, wherein the housing comprises a first containing cavity; the isolation layer is connected with the housing, and the first containing cavity is separated into a first cavity used for containing the massage device and a second cavity used for human body massage; the massage device comprises a base, a rotating disc and a power source; the base is connected with the housing; the rotating disc is rotationally connected to the base around a first rotating axis; a heating element and multiple massage bulges are arranged on one side, which is far away from the base, of the rotating disc; the multiple massage bulges are connected with the rotating disc and distributed around the rotating axis of the rotating disc; partial or total massage bulges are made of jade. The jade is heated by the heating element, so that far infrared rays beneficial to the human body can be generated, the functions are diversified, the requirements of users can be met, and the overall using effect is excellent. The foot bath bucket comprises the massager and has total functions of the massager.

Owner:重庆咏寿堂健身器材有限公司

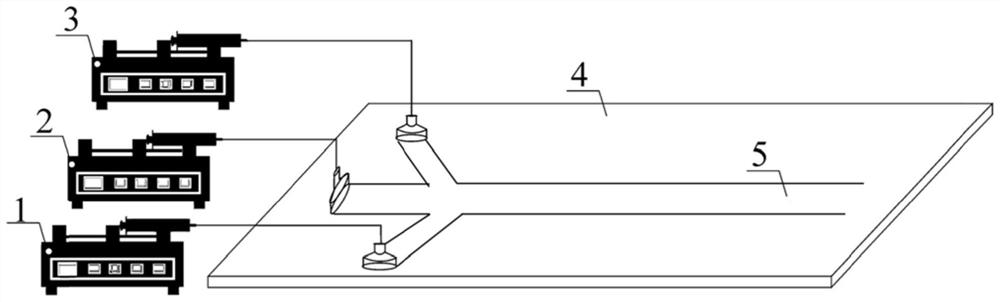

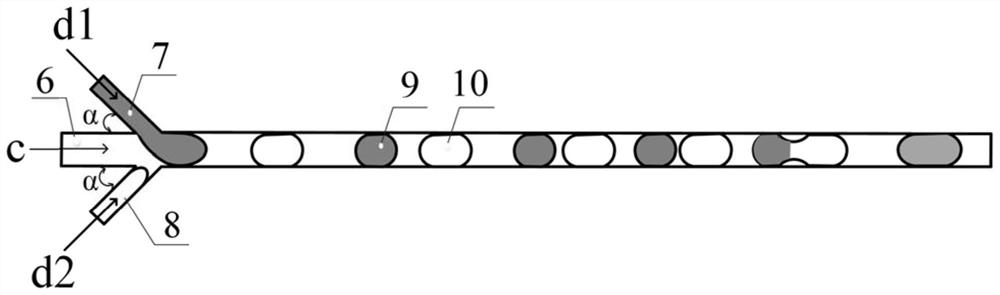

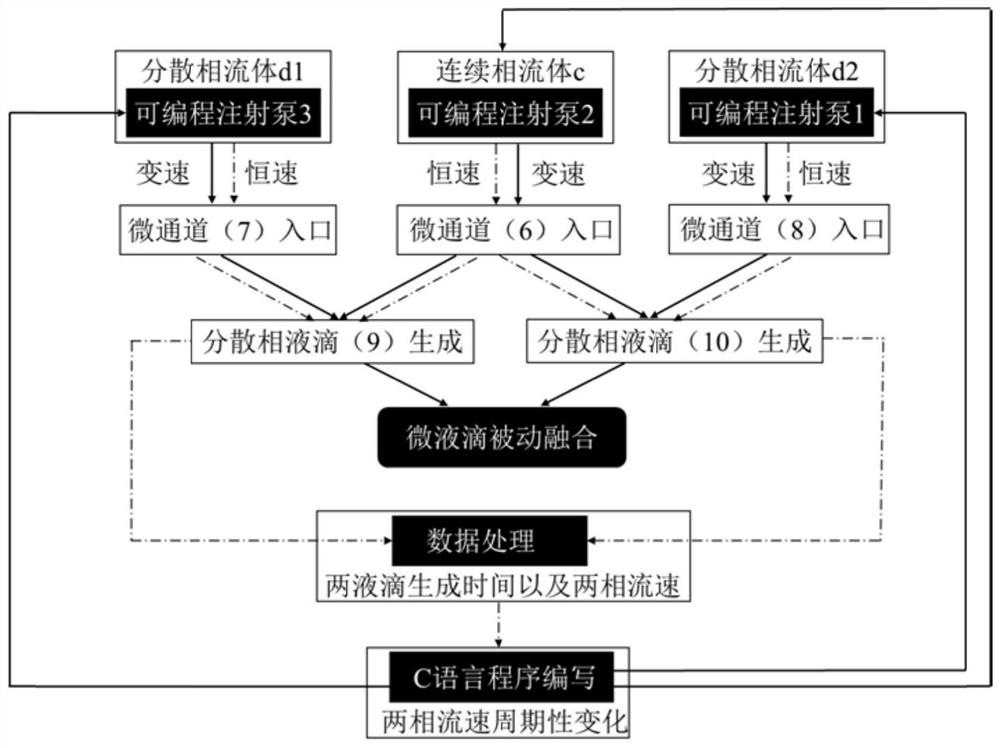

Device and method for realizing passive fusion of micro-droplets

ActiveCN111804353ASimple structureEasy to operateLaboratory glasswaresEngineeringMechanical engineering

The invention discloses a device and a method for realizing passive fusion of micro-droplets. The inlet end of a micro-channel main path is respectively communicated with a first micro-channel branchpath, a second micro-channel branch path and a third micro-channel branch path; the axis of the first micro-channel branch path is the same as the axis of the micro-channel main path, and the includedangle between the second micro-channel branch path and the first micro-channel branch path is the same as the included angle between the third micro-channel branch path and the first micro-channel branch; and a first injection pump injects a continuous phase fluid into the first micro-channel branch path, a second injection pump injects a first dispersed phase fluid into the second micro-channelbranch path, and a third injection pump injects a second dispersed phase fluid into the third micro-channel branch path. Under the condition that the device does not need to be provided with a complexmicro-channel structure, efficient fusion between micro-droplets can be achieved. Meanwhile, the plurality of groups of injection pumps and micro-channels can be arranged as required, so that the mutual fusion of a plurality of micro-droplets is realized.

Owner:ZHEJIANG UNIV

Noodle cooker and noodle cooking equipment

PendingCN107374343ASimple designIngenious designCooking vesselsTemperature controlProcess engineering

The invention provides a noodle cooker and noodle cooking equipment and belongs to the technical field of food processing. The noodle cooker comprises a cooker body, a pot, noodle leakage bracket, a noodle leakage unit, a relay, a temperature control switch, a heating system, a first power supply, a second power supply and a control switch which is used for controlling the heating system to heat noodle cooking water; the cooker body is connected with the pot, and the pot is provided with a first containing cavity used for containing the noodle boiling water. The noodle cooker is high in automation degree, simple in operation and good in overall use effect; energy consumption is low, and noodles cooked are good in taste through accurate time control; the entire noodle cooker is ingenious in design, simple in operation and large in market application potential; the noodle cooking equipment comprises the noodle cooker and has all the functions of the noodle cooler.

Owner:孟建彬

Mouthpiece anti-loose device and anti-loose method

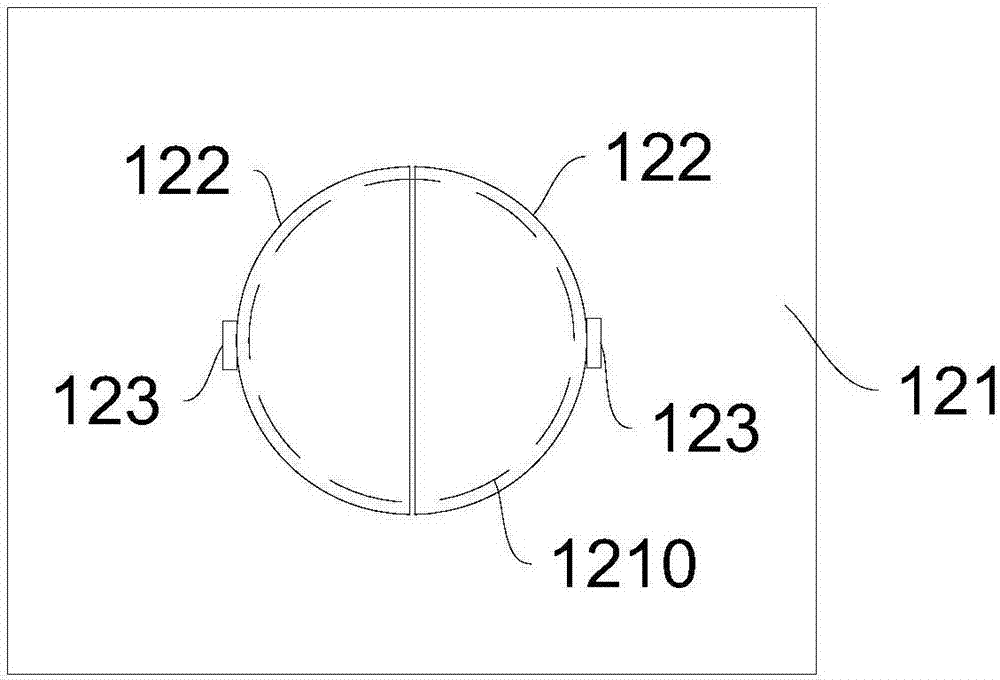

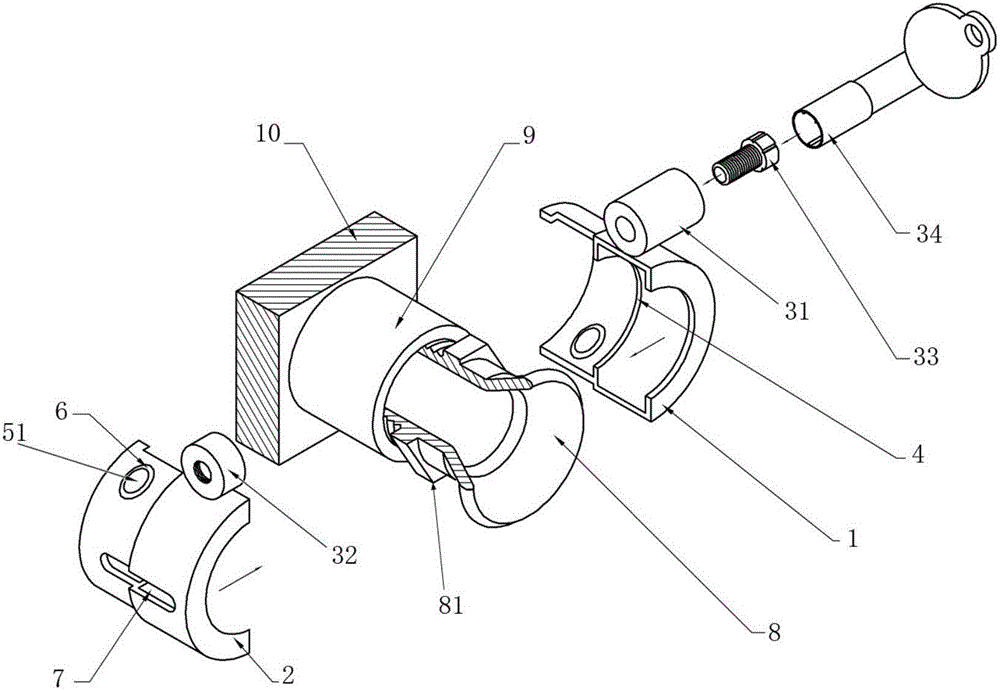

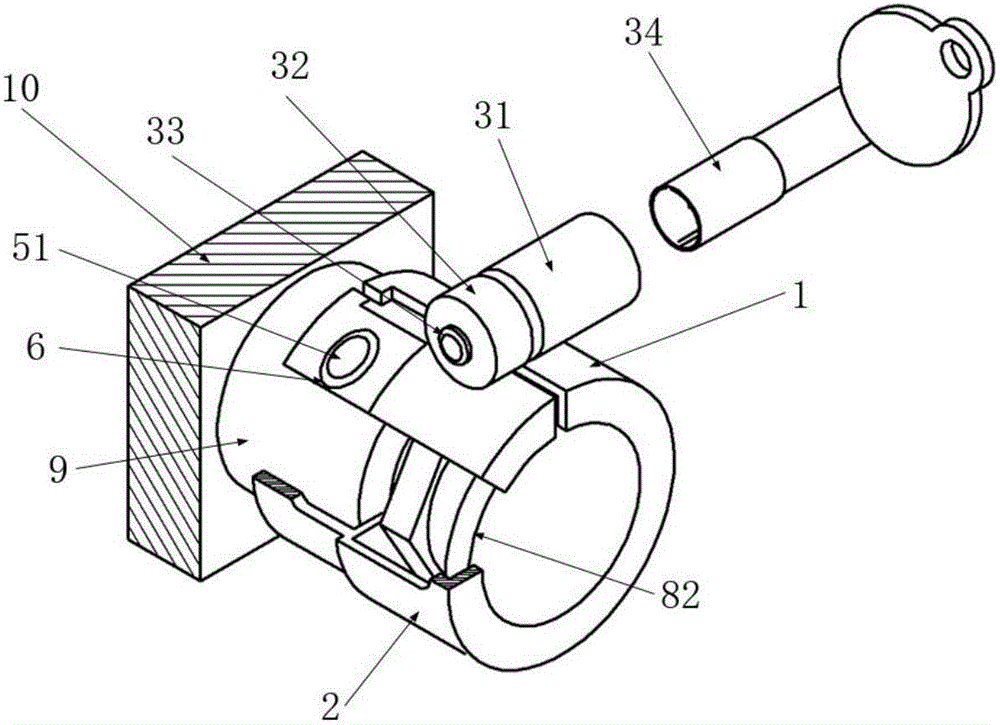

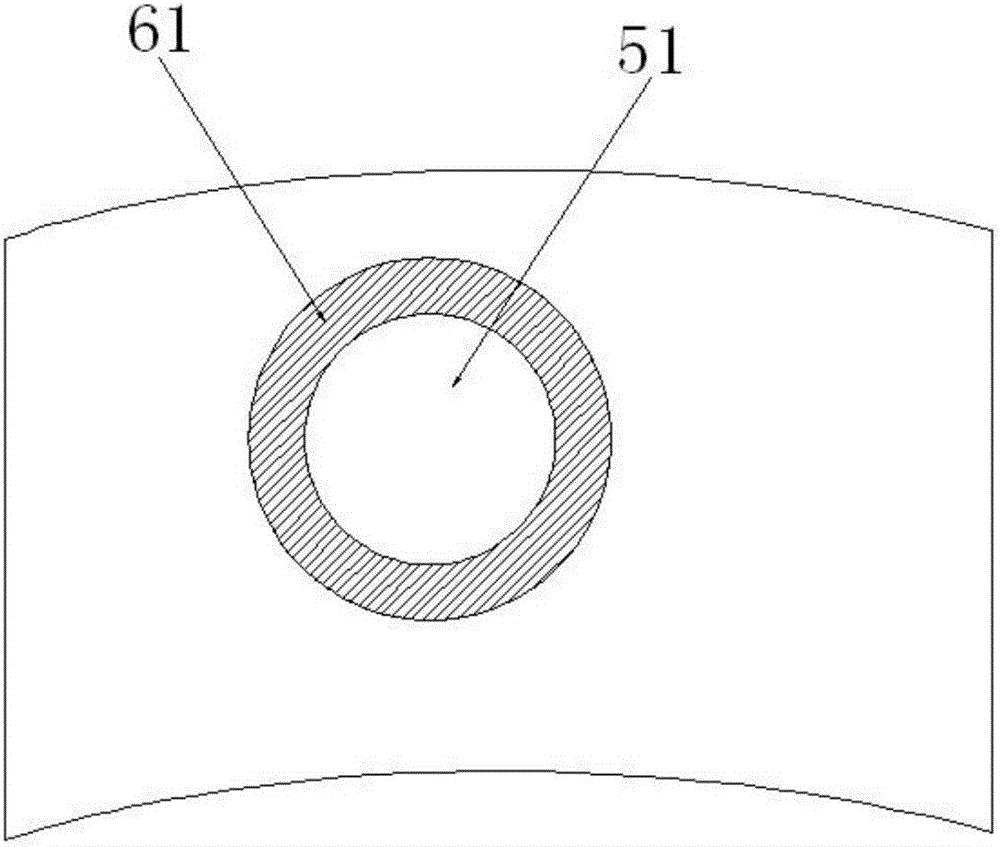

A horn nozzle anti-loosening apparatus and an anti-loosening method. The apparatus comprises a first lock body (1) and a second lock body (2) with semicircular cylindrical inner walls; locking components arranged on the first lock body (1) and the second lock body (2); locking rings (4) arranged on the inner walls of the first lock body (1) and the second lock body (2); a communicating joint (9) that matches the inner walls of the first lock body (1) and the second lock body (2); a horn nozzle (8) connected to the communicating joint (9); and anti-slip pads (6) installed on the inner walls of the first lock body (1) and the second lock body (2). An installation slot is formed between a front end of the communicating joint (9) and a horn side wall (82); or a bump (81) is arranged on the horn mouth, and an installation slot is formed between the bump and the horn side wall (82) or the front end of the communicating joint (9). The installation slot is used for clamping the lock rings (4). The anti-loosening method corresponds to the horn nozzle anti-loosening apparatus. The horn nozzle anti-loosening method and the apparatus are convenient and useful, and can effectively prevent an electrical device losing its explosion-resistance protection due to a horn nozzle being loosened by hand or by means of a non-specific tool.

Owner:SHANXI QUANAN NEW TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com