Inoculated alloy grain structure numerical value prediction method

A technology of numerical prediction and grain size, which is applied in electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as low calculation efficiency of three-dimensional macroscopic field, inability to accurately predict grain structure, etc., and achieve accurate grain structure Morphological distribution, huge market application potential, and the effect of improving computational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

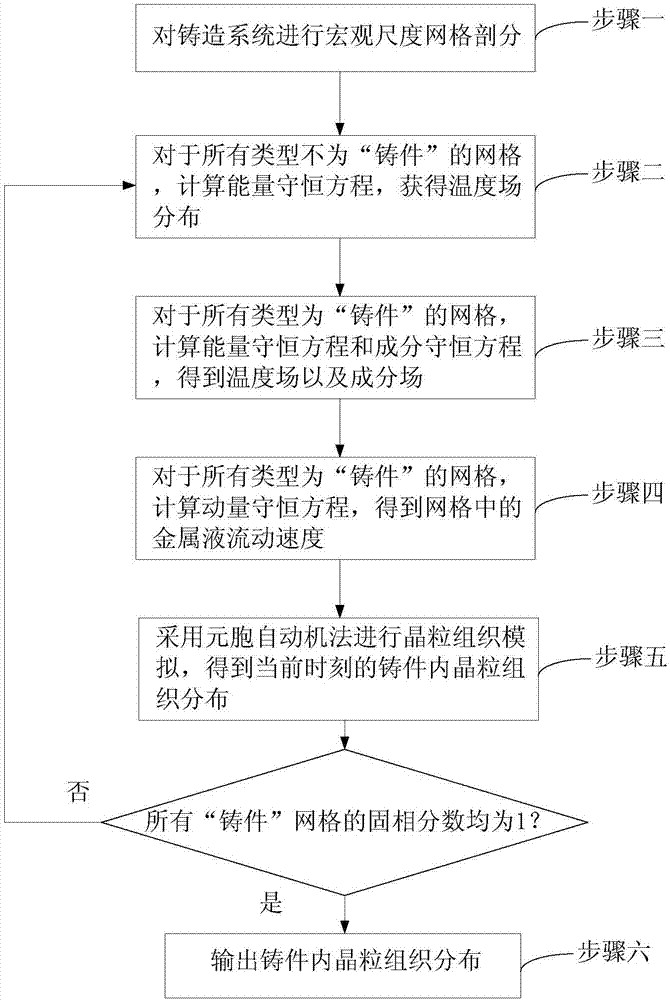

[0021] Embodiment 1: The numerical prediction method of inoculated alloy grain structure in this embodiment includes the following steps:

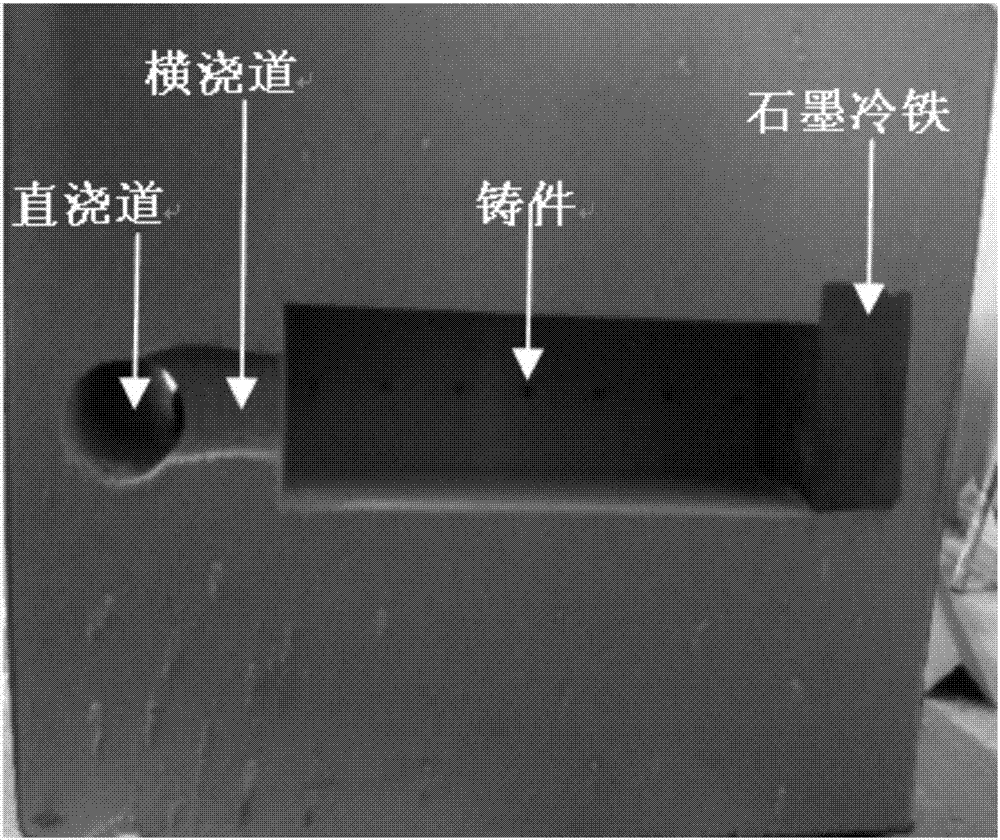

[0022] Step 1: Carry out macro-scale meshing of the casting system, and divide the casting system into (i,j,k) chan Several grids of , i, j, k represent the coordinate components along the X axis, Y axis, and Z axis, respectively, where the X axis, Y axis, and Z axis are arbitrary coordinate axes that are orthogonal to each other; chan represents the type of the grid. The selection of the X axis, the Y axis and the Z axis can be determined according to the actual situation. figure 2 It shows the physical picture of the casting cavity, and it is a top view. The method of selecting the three axes can be: vertically downward along the image direction is the positive direction of the X-axis, horizontally to the right along the image direction is the positive direction of the Y-axis, and along the direction of the image paper Outside is the p...

specific Embodiment approach 2

[0052] Specific implementation mode two: the difference between this implementation mode and specific implementation mode one is:

[0053] The minimum values of the casting system in the X-axis, Y-axis, and Z-axis directions are respectively X min , Y min ,Z min , the maximum values in the directions of X-axis, Y-axis and Z-axis are respectively X max , Y max ,Z max , Step 1 is specifically:

[0054] Step 11: Select the cross-section S1, the first auxiliary plane S2, the second auxiliary plane S3 and the coordinate axes of the grain structure to be simulated; the selection method is:

[0055] If the selection is perpendicular to the Z axis and the position is Z s1 plane, then the meshing steps adopted by the section S1 in the X-axis direction and the Y-axis direction are Δx 1 and Δy 1 ;Taking S1 as the reference plane, the section parallel to the S1 section and along the positive direction of the Z axis, and the distance from the S1 section is δ meters is S2, paral...

specific Embodiment approach 3

[0066] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is:

[0067] In step one and two, δ=0.006m.

[0068] If the selection is perpendicular to the Z axis and the position is Z s1 plane, then Δx 1 =Δy 1 , Δz 1 =0.002m, Δx 2 =3Δx 1 , Δy 2 =3Δy 1 ,Δz 2 =3Δz 1 .

[0069] If the selection is perpendicular to the X axis and the position is X s1 plane, then Δy 1 =Δz 1 , Δx 1 =0.002m, Δz 2 =3Δz 1 , Δy 2 =3Δy 1 ,Δx 2 =3Δx 1 .

[0070] If the selection is perpendicular to the Y axis and the position is Y s1 plane, then Δz 1 =Δx 1 , Δy 1 =0.002m, Δz 2 =3Δz 1 , Δx 2 =3Δx 1 ,, Δy 2 =3Δy 1 .

[0071] Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com