Centrifugal washing equipment and centrifugal washing method

A technology for centrifugal washing and equipment, which is applied in biochemical equipment and methods, biochemical cleaning devices, bioreactors/fermenters for specific purposes, etc., and can solve problems such as low efficiency, large floor space, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

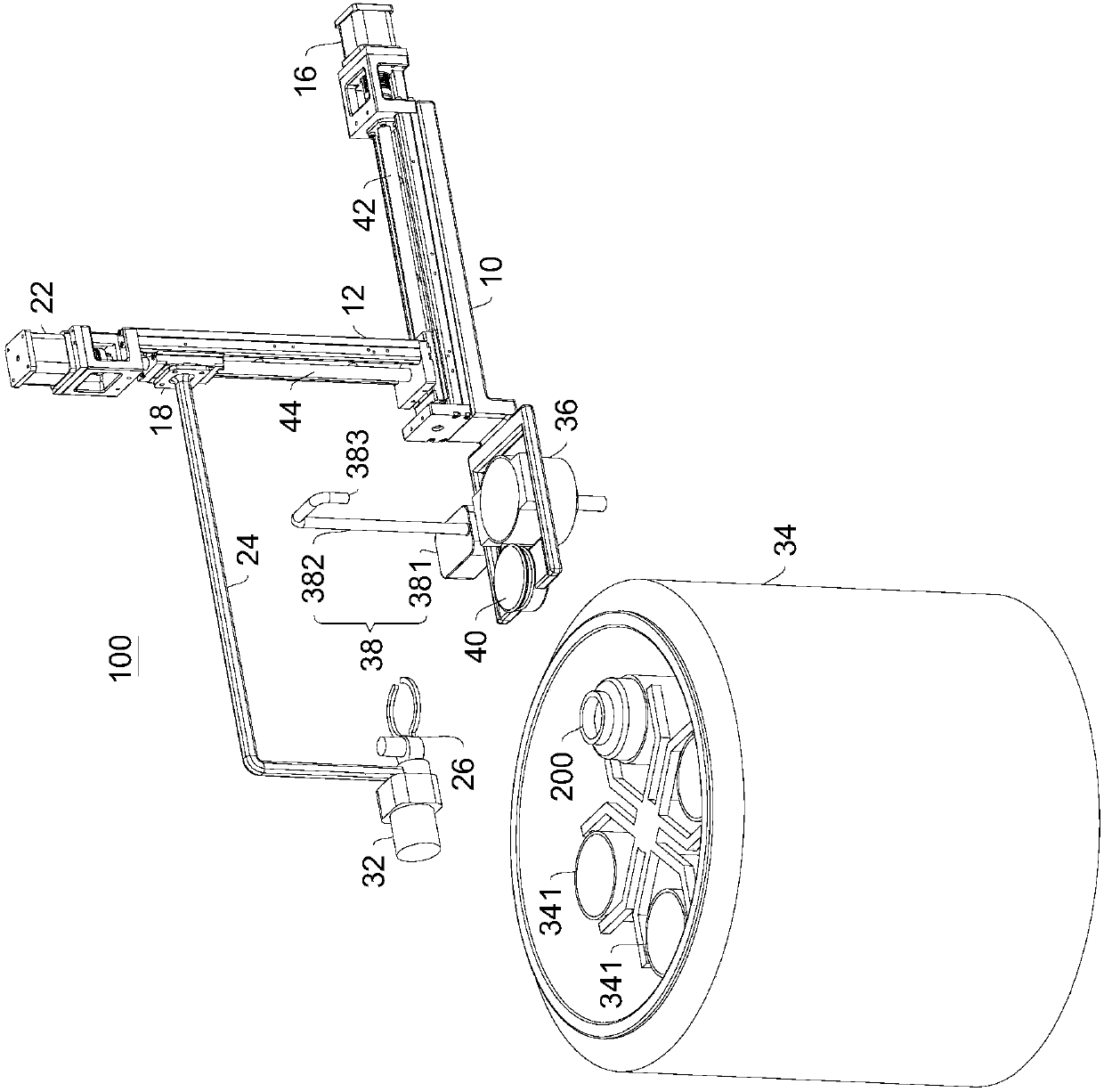

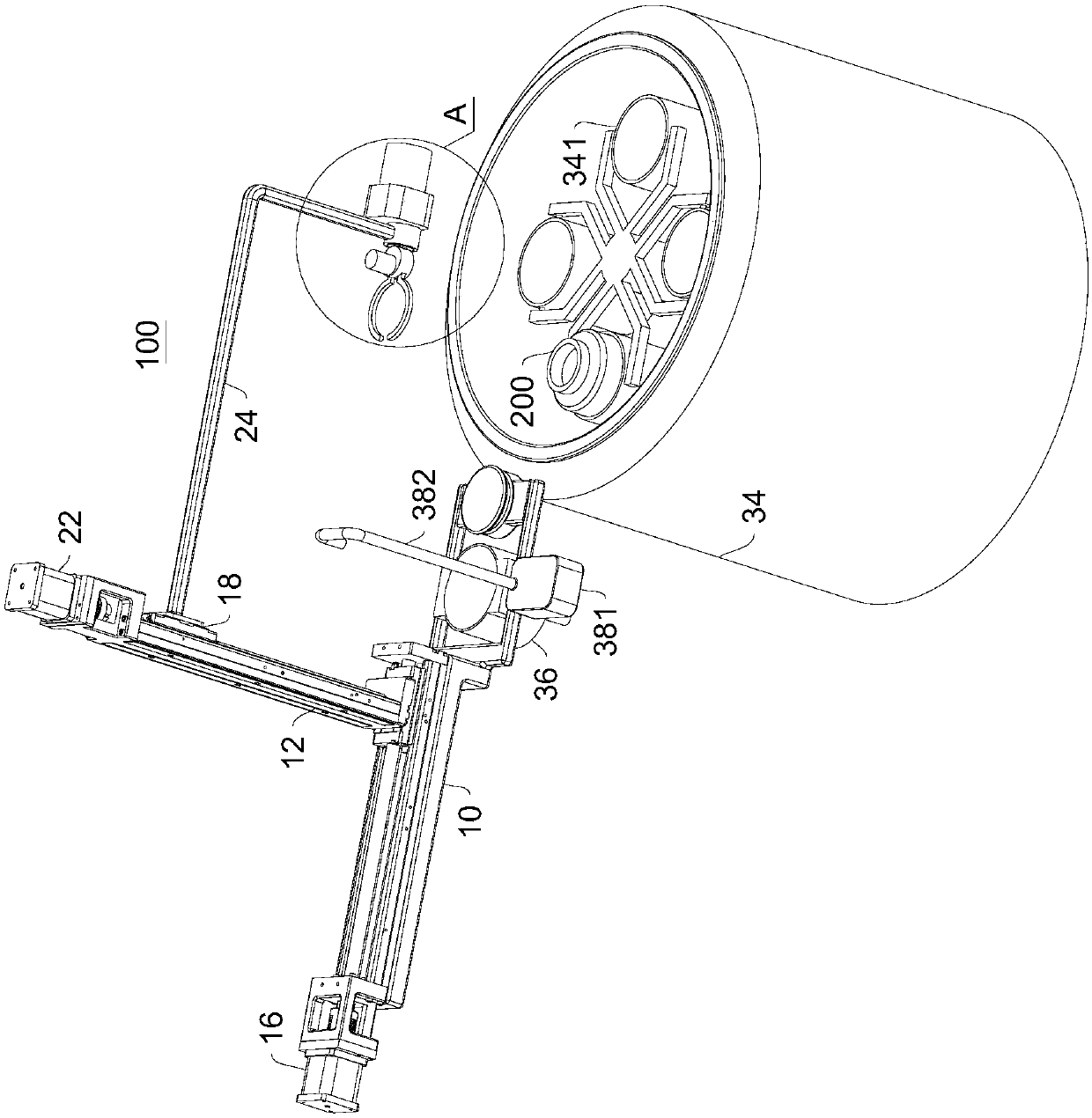

[0057] Please refer to Figure 1-Figure 6 , the present embodiment provides a centrifugal washing device 100, which includes:

[0058] Rack 10;

[0059] The first sliding member 12, the first sliding member 12 is slidably connected to the frame 10 along the first axis 14;

[0060] The first driving member 16, the first driving member 16 is connected with the frame 10 and used to drive the first sliding member 12;

[0061] The second sliding member 18, the second sliding member 18 is slidably connected to the first sliding member 12 along the second axis 20, the first axis 14 is arranged horizontally, and the second axis 20 is arranged vertically;

[0062] The second driving member 22, the second driving member 22 is connected with the first sliding member 12 and used to drive the second sliding member 18;

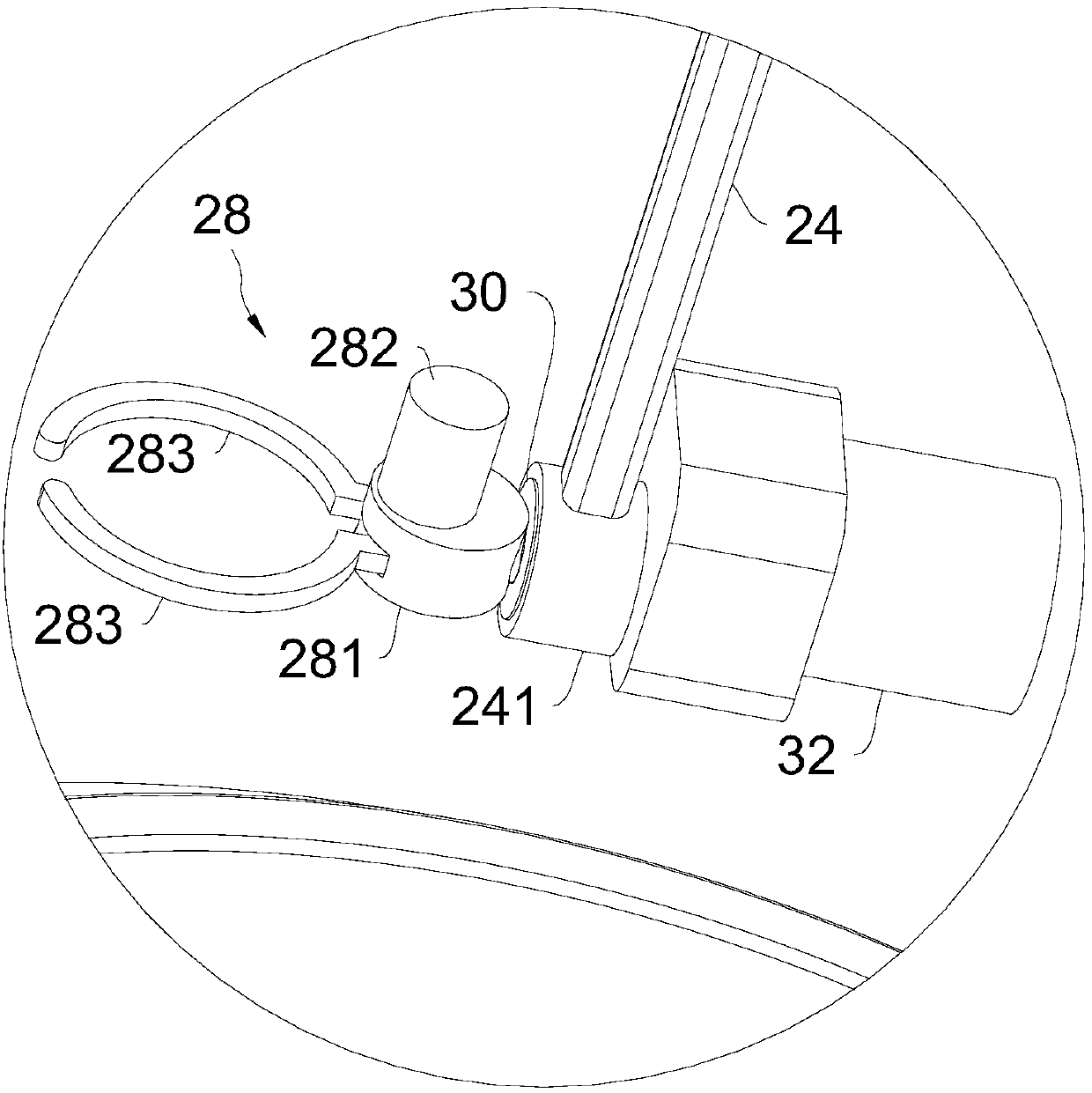

[0063] A connecting piece 24, one end of the connecting piece 24 is connected to the second sliding piece 18, and the other end of the connecting piece 24 is provided wi...

Embodiment approach

[0077] In one embodiment, the structure of the vibrating table 40 includes a motor, a cam mechanism and a vibrating platform. The motor makes the vibrating platform reciprocate quickly through the cam mechanism, thereby producing a vibrating effect. Generally, the base of the vibrating table 40 is fixed on the machine. 10 to improve the integration effect of the entire device.

[0078] In one embodiment, the mechanical clamping hand 26 is a clamper, which can be an electric clamper or a pneumatic clamper, as long as the centrifuge tank 200 can be clamped or loosened.

[0079] Generally, the first axis 14 can be understood as the X axis, and the second axis 20 can be understood as the Z axis. The horizontal and vertical here do not mean absolute horizontal or vertical, and certain deviations are allowed in specific implementation.

[0080] The first driving member 16 , the second driving member 22 and the third driving member 32 can be motors, electric cylinders, air cylinders,...

Embodiment 2

[0116] This embodiment provides a centrifugal washing method, which uses the centrifugal washing equipment 100 mentioned above, and the structure of the centrifugal washing equipment 100 can refer to Example 1.

[0117] The method includes:

[0118] The mechanical gripper 26 is located above the centrifuge 34;

[0119] After the centrifuge 34 completes the centrifugal operation, the centrifuge 34 is opened, and the control device controls the second driving member 22, so that the mechanical clamping hand 26 is stretched into the centrifuge 34, and the centrifuge tank 200 in the centrifuge 34 is clamped, and the The mechanical clamping hand 26 is promoted;

[0120] The control device controls the first driving member 16 to move the mechanical clamping hand 26 to the top of the waste liquid pourer 36, and the control device controls the third driving member 32 to dump the centrifuge tank 200. After the centrifuge tank 200 is dumped, the control device Control the third driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com