Drill barrel device and drilling machine

A drill pipe and drill pipe technology, used in drill bits, drilling equipment, earth-moving drilling, etc., can solve problems such as poor use effect and inability to remove sediment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

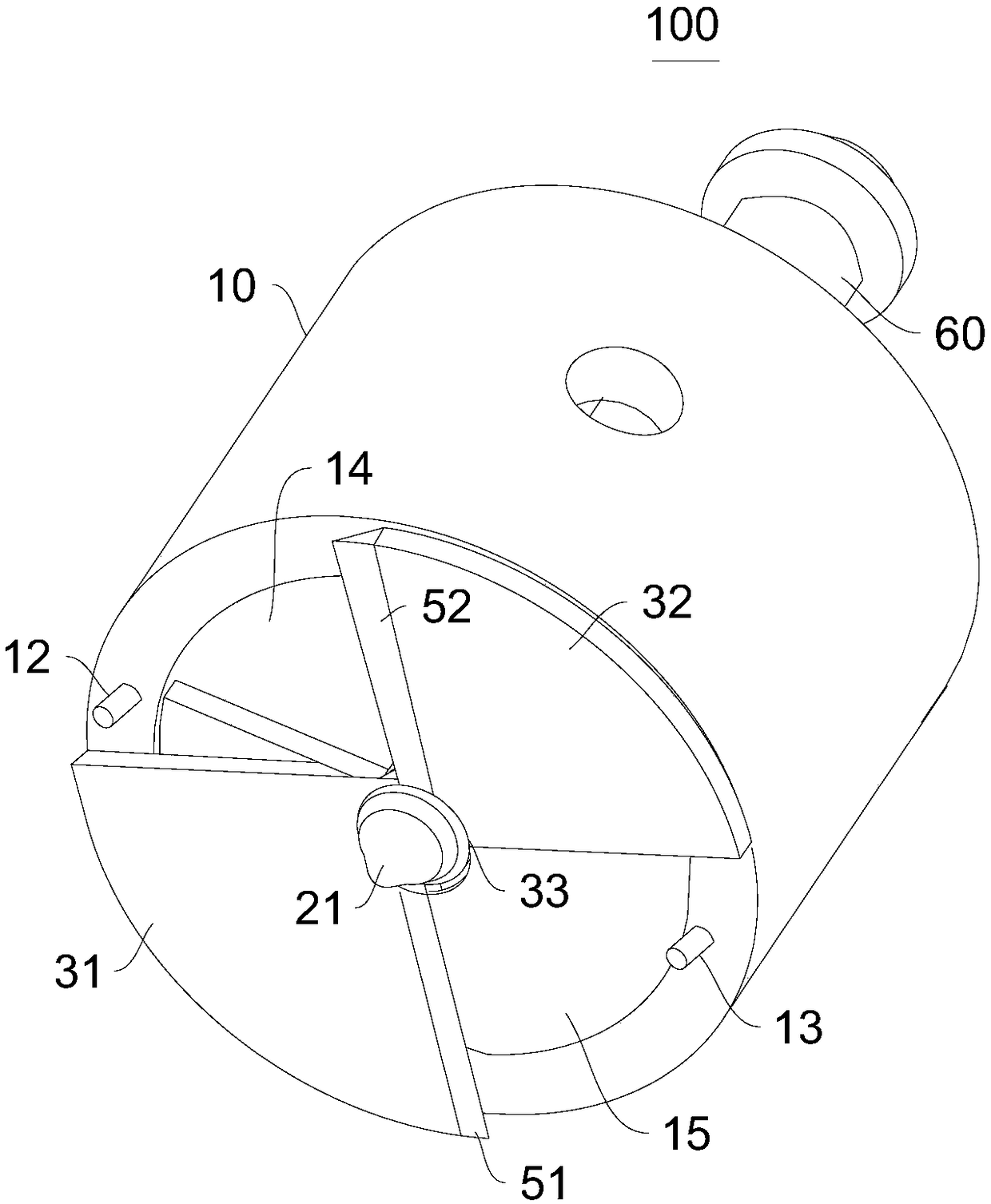

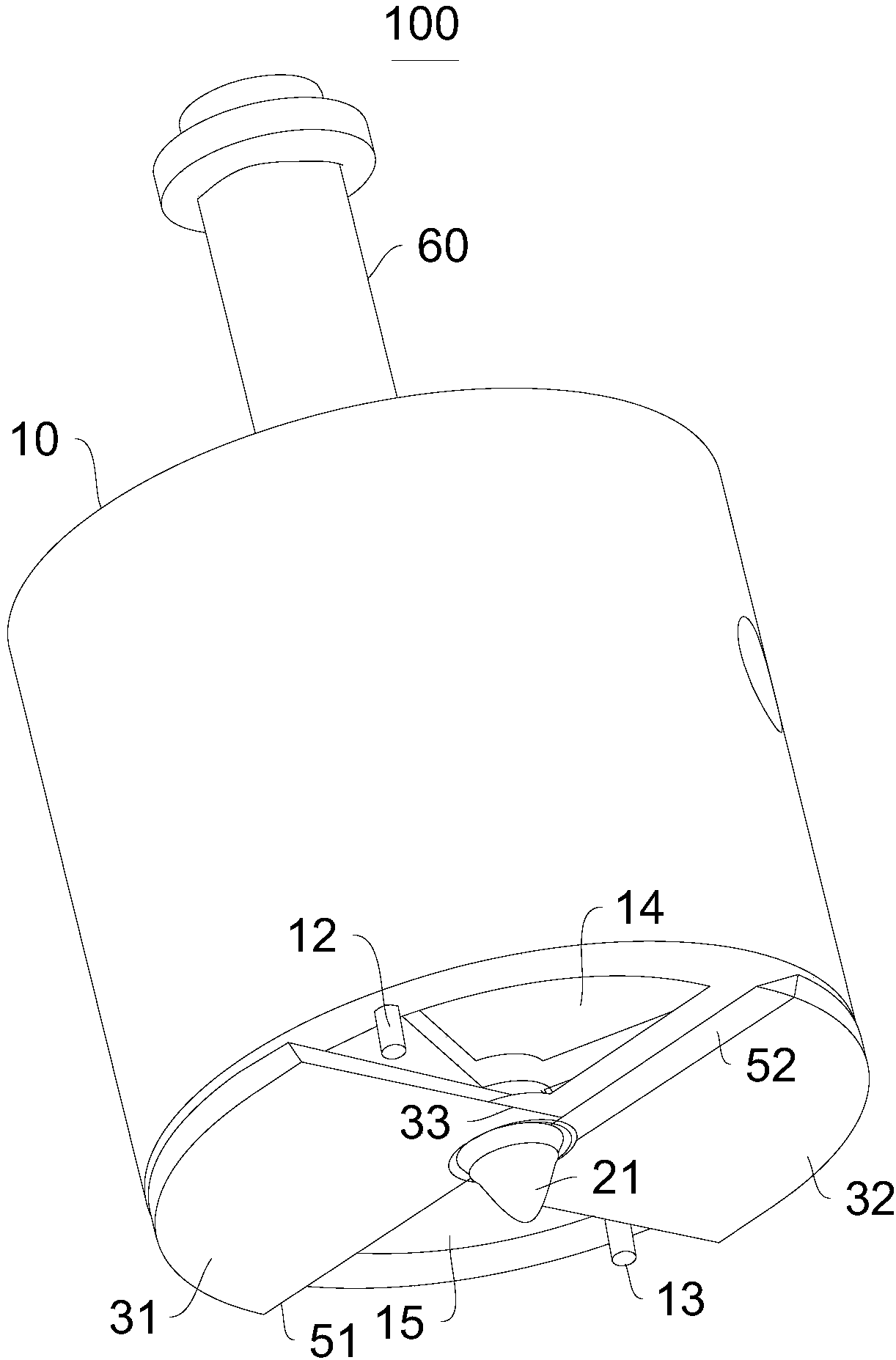

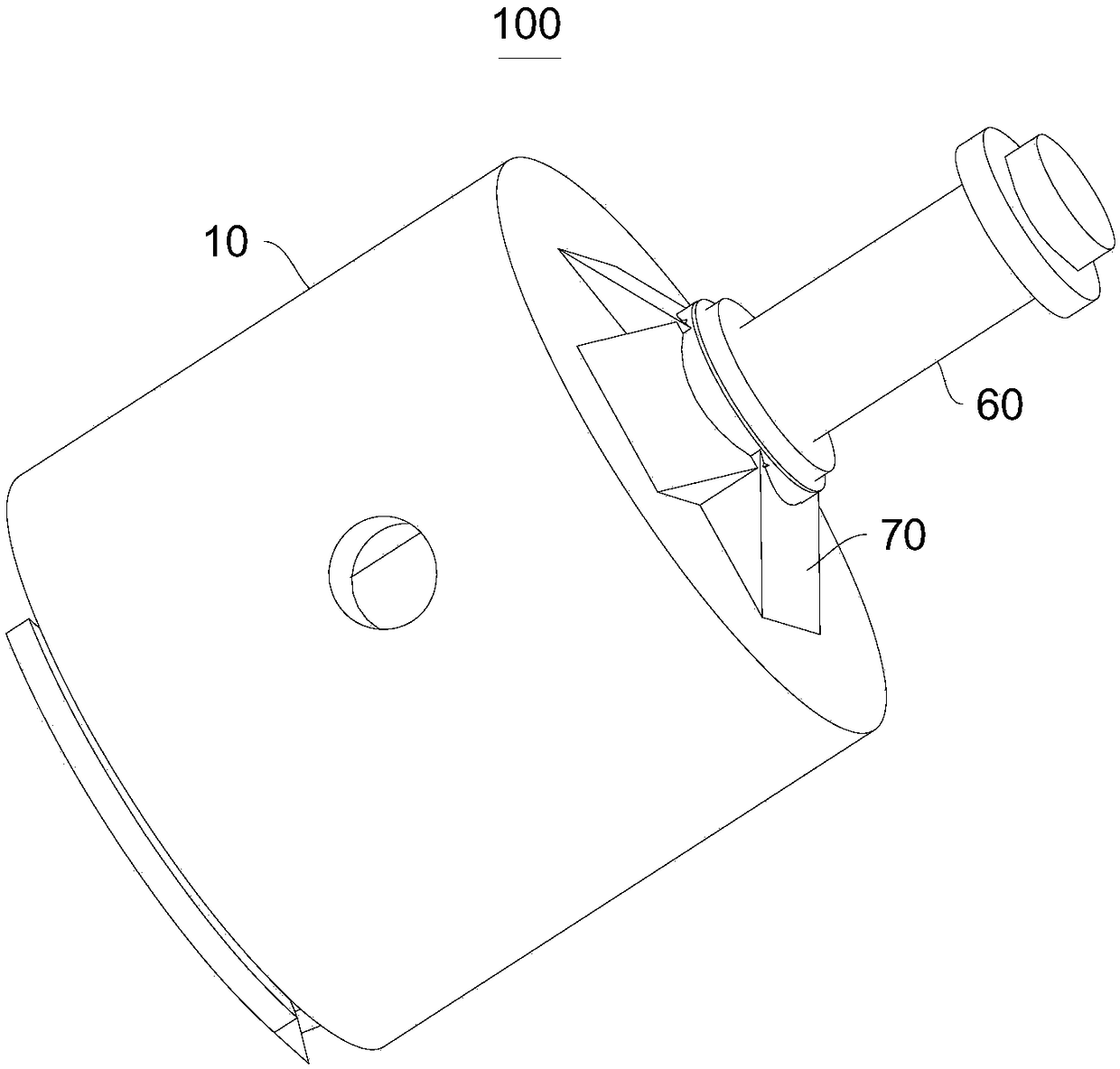

[0050] Please refer to Figure 1-Figure 7 , the present embodiment provides a drill pipe device 100, which includes:

[0051] Drill barrel body 10, the drill barrel body 10 has an accommodation cavity 11, the bottom of the drill barrel body 10 is provided with an opening communicating with the accommodation cavity 11, and the bottom of the drill barrel body 10 is provided with a positioning member;

[0052] A drill rod 20, one end of the drill rod 20 is connected to the drill barrel body 10, and the other end of the drill rod 20 is provided with a drill bit 21, and the drill bit 21 extends out of the accommodation chamber 11;

[0053] A closure, the closure is rotatably connected to the drill pipe 20, and the closure is provided with a drilling blade;

[0054] The drill pipe device 100 has a drilling state in which the drill pipe body 10 rotates along a first preset direction, the locating member resists and drives the sealing member to open the opening, and the drill pipe bo...

Embodiment 2

[0092] This embodiment also provides a drilling machine, which includes the above-mentioned drill pipe device 100 , which has all the functions of the drill pipe device 100 .

[0093] For the structure of the drill pipe device 100, reference may be made to Embodiment 1.

[0094]In summary, the present invention provides a drill pipe device 100, which can clean the sediment at the bottom of the pile foundation, which is beneficial to reduce the thickness of the sediment at the bottom, improve the primary hole formation rate of the pile foundation, and greatly reduce the economic cost. The structure design is reasonable, the overall use effect is better, and the market application potential is huge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com