Lamellar double-phase high-strength and high-toughness steel and preparation method thereof

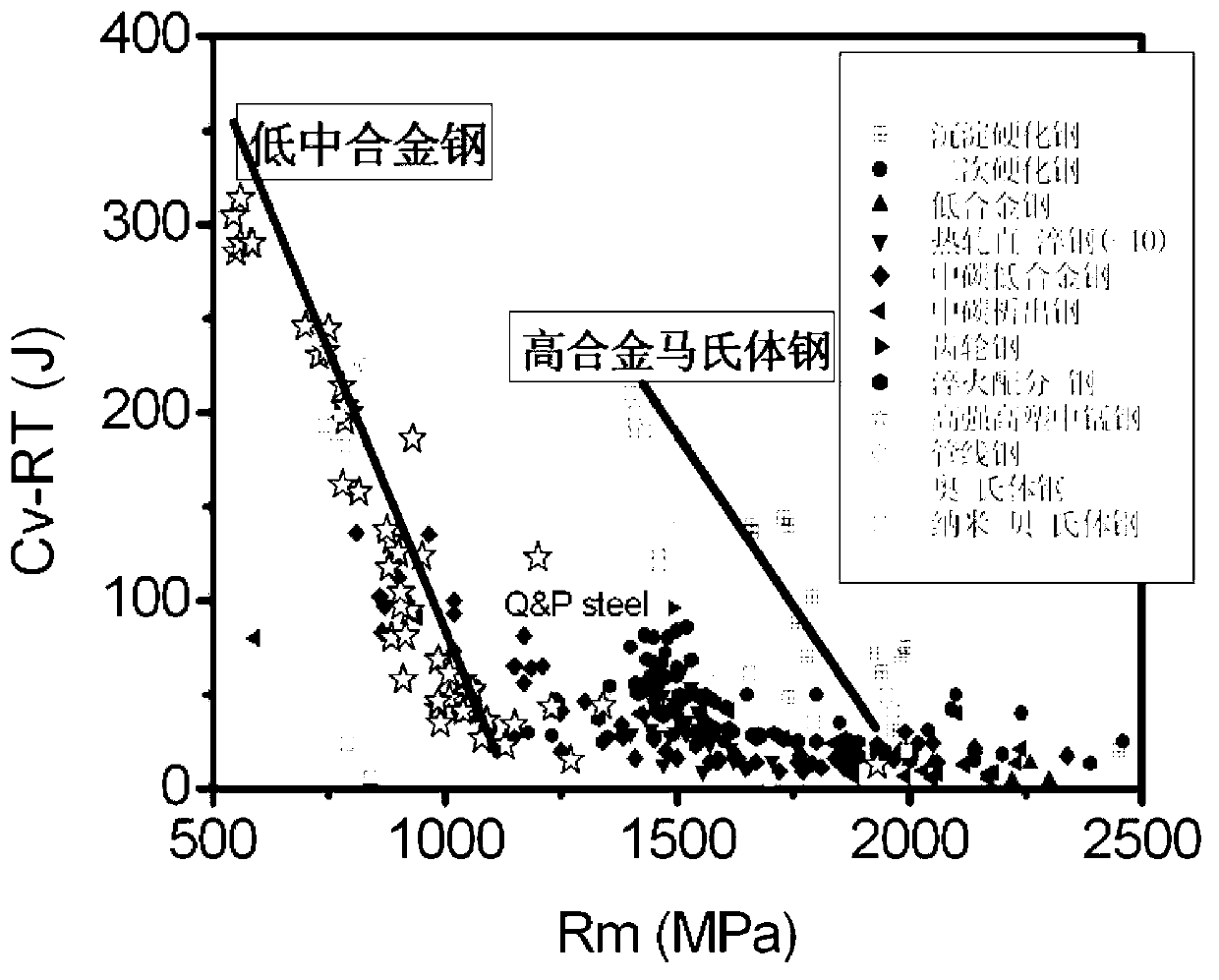

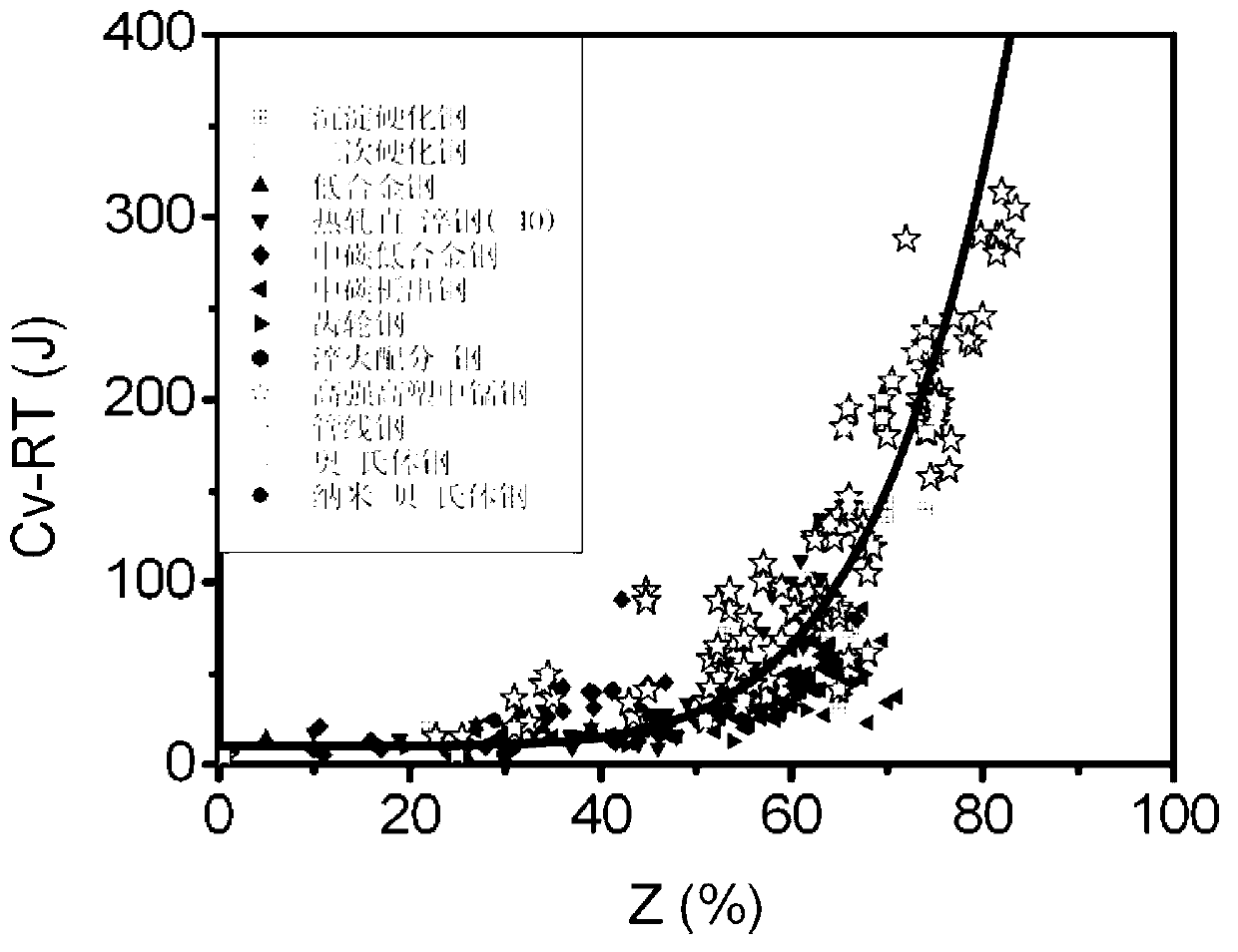

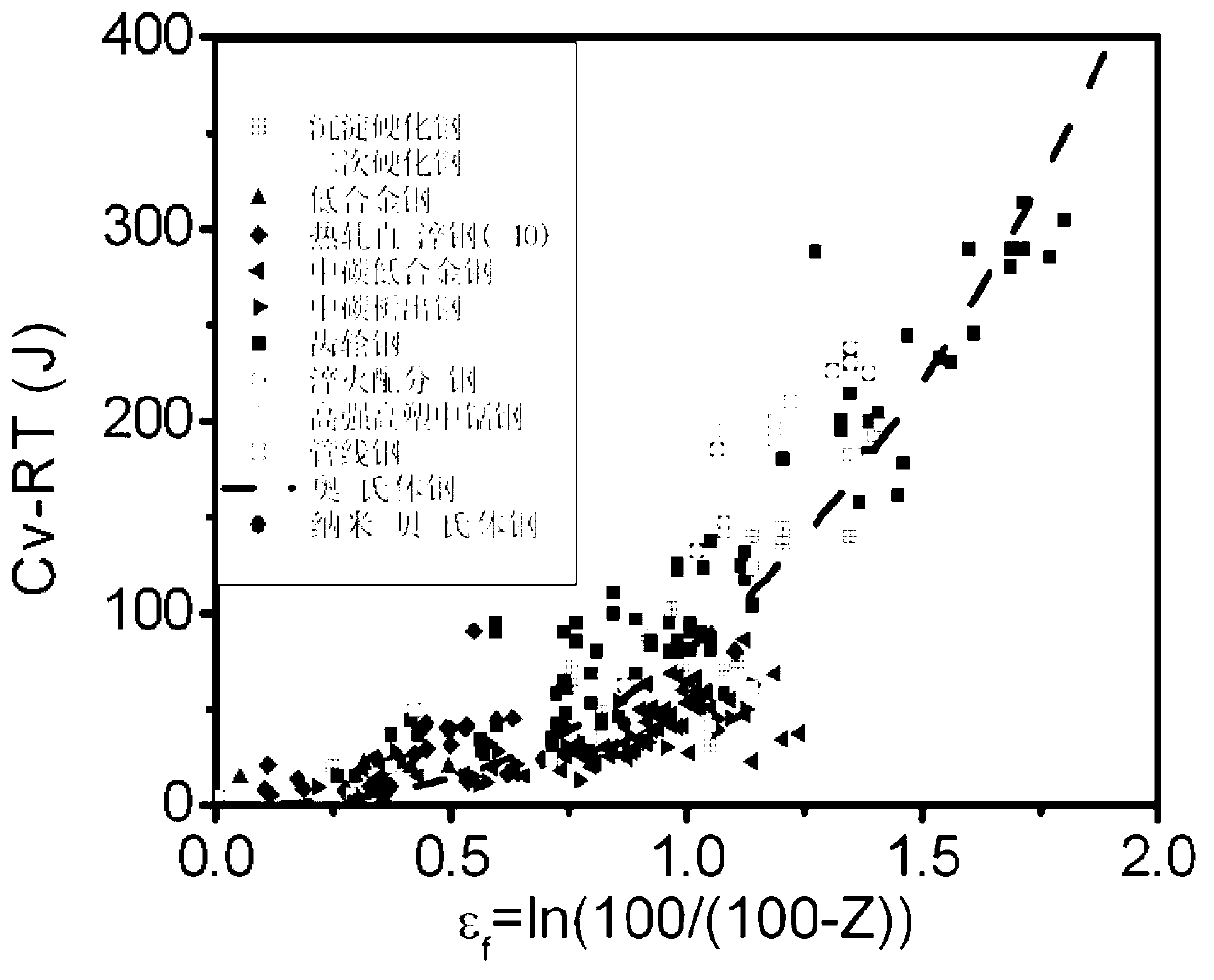

A lamellar, high-toughness steel technology, applied in the field of high-toughness and high-strength steel, can solve the problems that the micro-region deformation capacity is difficult to reach 70% surface shrinkage, increase the cost of steel, etc., achieve huge market application potential, and improve comprehensive performance. , the effect of excellent high strength and high toughness matching performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Example 1: High-strength and high-toughness rod and wire

[0072] Steel smelting and forging:

[0073] The steel of the present invention is smelted by a laboratory vacuum induction furnace, and the casting ingot shape is a 50kg round ingot. A total of 10 furnaces of steel are smelted for forging rod-shaped samples. The chemical composition is shown in Table 1. The steel ingots of D1-D10# are heated at 1100-1250°C, kept for 2-5 hours, and then forged and opened. The forging temperature range is 800-1150°C, forging a square with an initial cross-sectional size of 40mmx40mm to a circle with a cross-sectional size of φ16mm, and air cooling after forging. Finally, it is forged into a bar with a size of φ16mm×1000mm and cooled by air cooling. This process can obtain acicular ferrite and martensite structure. Carry out the determination of mechanical properties and impact toughness (tensile test tensile rate is 10 -4 / s, the elongation rate is A5, impact test: V-shaped im...

Embodiment 2

[0080] Embodiment 2: Hot-rolled high-toughness plate

[0081] Steel smelting and hot rolling:

[0082] The steel of the present invention is smelted by a vacuum induction furnace in a laboratory, and the casting ingot shape is a 150kg round ingot. A total of 10 furnaces of steel are smelted for hot rolling. The chemical composition is shown in Table 3. The ingots of RZ1-RZ10# steel are heated at 1100-1250°C, held for 2-5 hours, and then forged and billeted. The forging temperature range is 800-1150°C, and the forging billet with an initial section size of 60mmx100mmx200mm. The forged billet is heated at 1100-1250°C, rolling is started at 1100-1200°C, and the final rolling temperature is about 800°C, wherein the reduction in the non-recrystallized zone at 1100-1000 degrees in the high-temperature dual-phase region accounts for 50% of the total reduction. %, while the reduction in the recrystallization zone at 1000-800 degrees is less than 50%. Evenly distribute the pass redu...

Embodiment 3

[0088] Embodiment 3: low temperature annealing and high temperature tempering treatment

[0089] Heat treatment of forged bars and hot-rolled plates:

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com