Body-centered cubic alloy microscopic segregation numerical prediction method

A numerical prediction, body-centered cubic technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve the problem of inability to accurately predict the micro-segregation of body-centered cubic alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

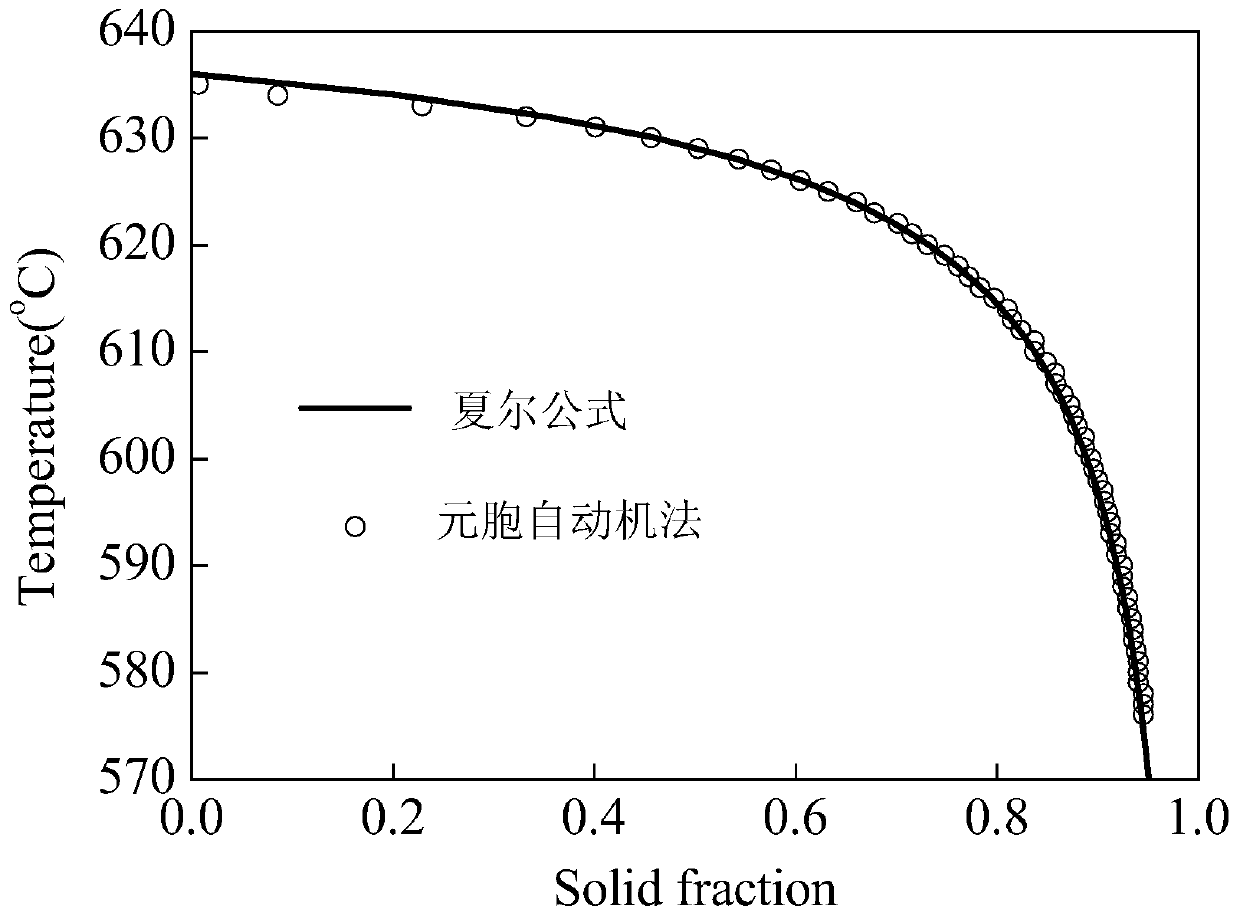

[0076] Specific implementation mode 1: In this implementation mode, a specific process of a numerical prediction method for microscopic segregation of body-centered cubic alloys is as follows:

[0077] Step 1. The dendrite growth calculation domain is in the Cartesian coordinate system, and the dendrite growth calculation domain (already determined) is divided into micro-scale grids, and a square grid with a side length of Δlen is used, and each square grid is used (j,k) logo;

[0078] j represents the coordinate along the X-axis direction of the rectangular coordinate system, k represents the coordinate along the Y-axis direction of the rectangular coordinate system, the value range of j is [1,n], and the value range of k is [1,m]; j and k is an integer, and m and n are even numbers, so there are m×n grids in the dendrite growth calculation domain;

[0079] Step 2. In order to overcome the influence of grid anisotropy on the calculation of dendrite growth, pairing between sq...

specific Embodiment approach 2

[0133] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in the step 3, neighbor objects are assigned to each group of paired grids in the dendrite growth calculation domain, and dendrite growth is completed by capturing the neighbor objects; The process is:

[0134] The labels are (j∈[1,2], k∈[1,m]), (j∈[n-1,n], k∈[1,m]), (j∈[3,n-2] , k∈[1,2]), (j∈[3,n-2)],k∈[m-1,m]) are defined as boundary grids, which do not participate in dendrite growth, so no need assign the neighbor object;

[0135] Each of the remaining paired grids has 4 sets of paired neighbor grids: when the paired grid group consists of (j,k), (j-1,k), (j,k-1) and (j-1 ,k-1) these four grids, then the first group of neighbor grids consists of (j-2,k), (j-3,k), (j-2,k-1) and (j- 3,k-1), the second set of neighbor grids consists of (j+2,k), (j+3,k), (j+2,k-1) and (j+3,k-1) The third group of neighbor grids consists of (j,k-2), (j-1,k-2), (j,k-3) and (j-1,k-3), the fourth group of neigh...

specific Embodiment approach 3

[0138] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the state of each square grid in the solidification process is determined in the step four; the process is:

[0139] The boundary grid defined in step 3 can only be in liquid state, that is, state(j,k)=0, state(j,k) is the state of the grid; other grids can have three states:

[0140] when f s When (j,k)=0, it is liquid, state(j,k)=0;

[0141] when 0s When (j,k)<1, it is in the growth state, state(j,k)=1;

[0142] when f s (j,k)=1 and f of the paired grid s Also equal to 1, it will be transformed into a solid state, state(j,k)=2;

[0143] f s (j,k) is the solid phase fraction of the square grid (j,k) (the solid phase fraction of the square grid (j,k) that divides the dendrite growth calculation domain (already determined) into a micro-scale grid ).

[0144] Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com