Ingot casting macrosegregation numerical simulation method

A technology of numerical simulation and macrosegregation, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as inaccurate prediction, and achieve the effect of huge market application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

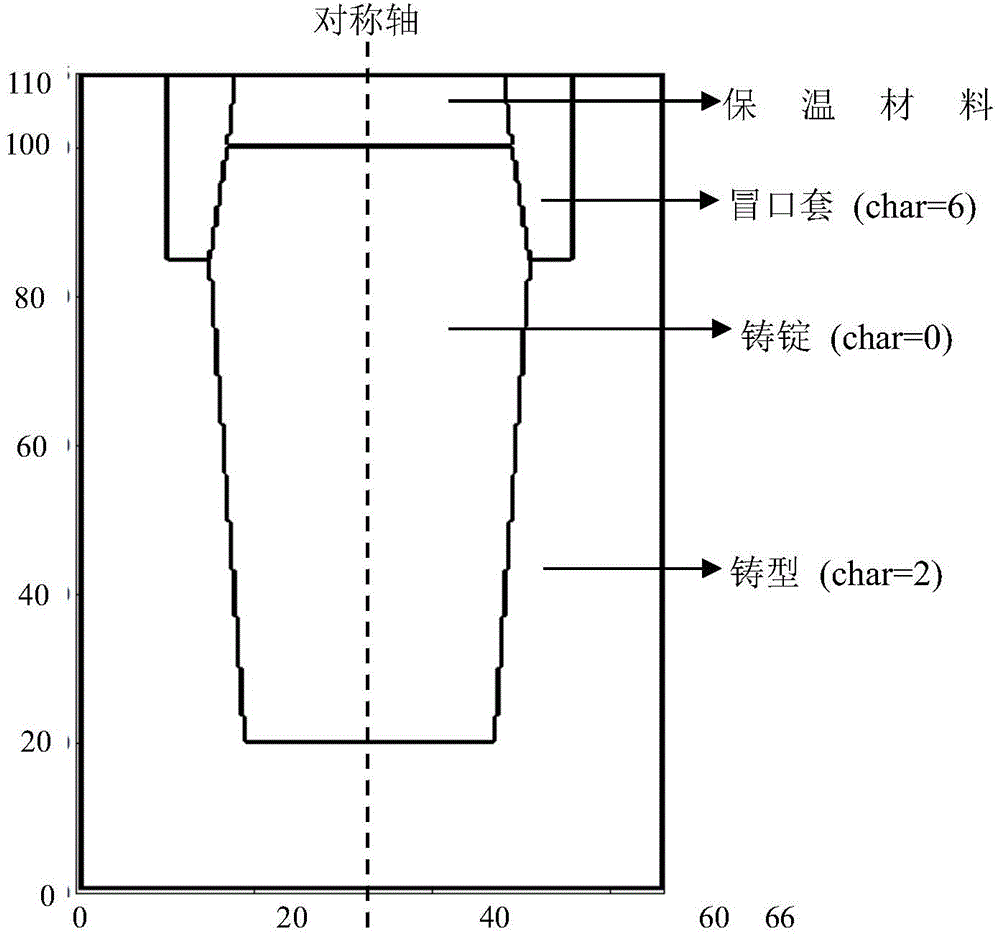

[0029] The numerical simulation method for ingot macro-segregation in this embodiment, such as Figure 9 As shown, the numerical simulation method for ingot macrosegregation is realized through the following steps:

[0030] Step 1. In the X direction and Y direction of the ingot casting system of X×Y meters, perform macro-scale grid division with the grid division step size △x in the X direction and the grid division step size △y in the Y direction, respectively. , forming a series of computing grids, and by (j, k) char=z Indicates the type of computing grid;

[0031] Among them, △x=△y, the value ranges of △x and △y are both 1×10 -3 ~4×10 -3 m; j, k and z are all integers, j represents the label of the grid in the direction of the X axis in the two-dimensional array, and the value range of j is 1 to M, k represents the label of the grid in the Y-axis direction in the two-dimensional array, and the value range of k is 1 to N. z represents the type of calculation grid, an...

specific Embodiment approach 2

[0037] The difference from Embodiment 1 is that the numerical simulation method for ingot macrosegregation in this embodiment, when the calculation grid type z takes different values, it represents different types of grids, specifically: when z=2, ( j, k) char=2 Indicates the casting grid; when z=0, (j,k) char=0 Indicates the ingot grid; when z=4, (j, k) char=4 Indicates the internal cooling iron grid; when z=5, (j, k) char=5 Indicates the outer cooling iron grid; when z=6, (j, k) char=6 Indicates the riser grid; when z=7, (j, k) char=7 Indicates the thermal insulation material grid; when z=8, (j, k) char=8 Represents a mesh of insulating materials.

specific Embodiment approach 3

[0038] The difference from the specific embodiment 1 or 2 is that in the numerical simulation method of ingot macrosegregation in this embodiment, the process of obtaining the temperature T distribution inside the ingot grid as described in step 3 is, through the energy conservation equation:

[0039] h s = c PL T, h l = c PL T+△H, [H]=f s h s +(1-f s ) h 1 , to obtain the distribution of temperature T in the ingot:

[0040] ρ L ∂ [ H ] ∂ t + ρ L ▿ · ( c P L U → T + U → Δ H ) = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com