Preparation method for primary-silicon-refinement high-silicon aluminum alloy rheological slurry

A high-silicon aluminum alloy and primary silicon technology is applied in the field of preparation of high-silicon aluminum alloy rheological slurry, which can solve the problems of high-silicon aluminum alloy primary silicon coarseness, etc., and achieve excellent mechanical properties, which are beneficial to industrial production and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

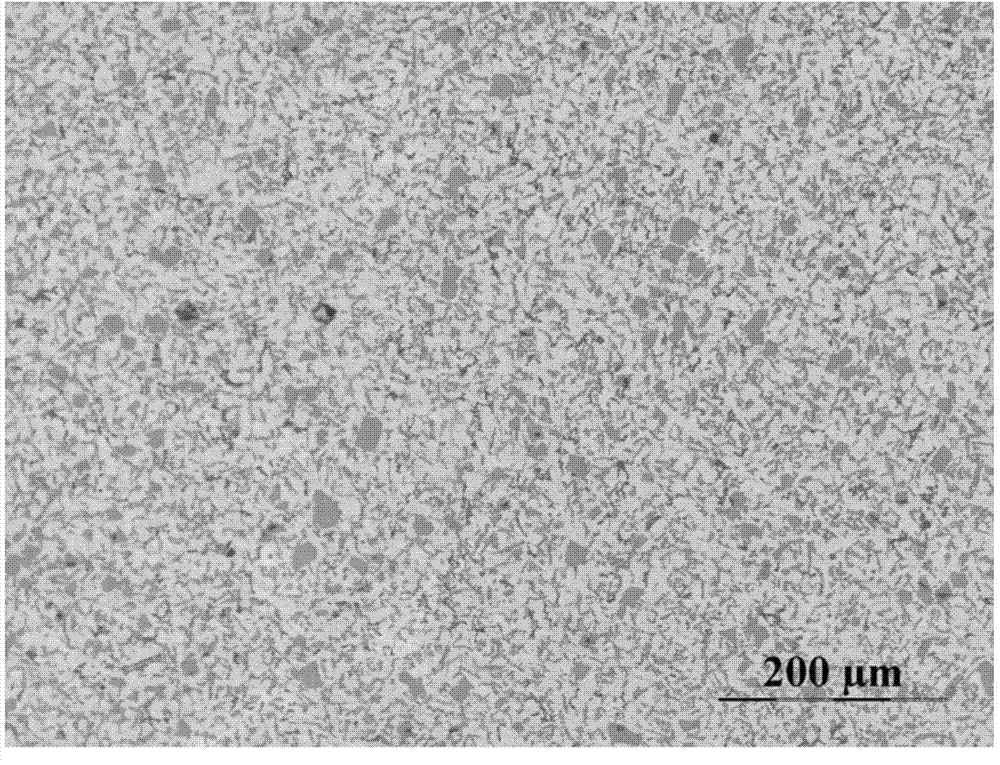

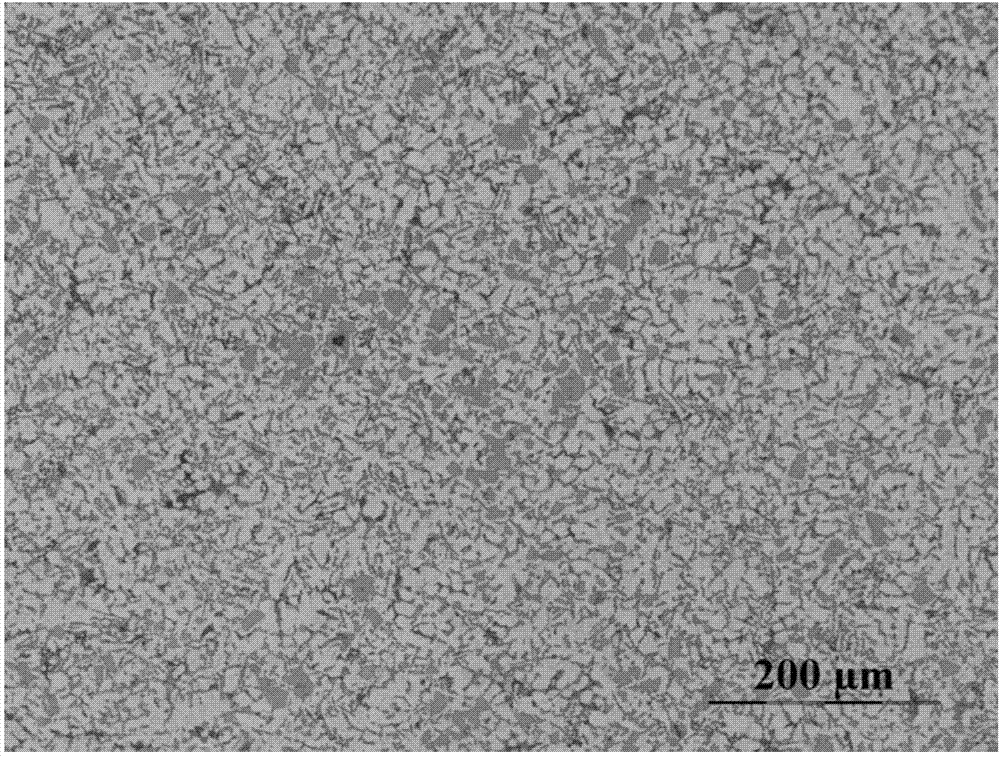

[0040] Al-18Si alloy primary silicon refinement and preparation of rheological slurry. The alloy was melted in a crucible resistance furnace, degassed and refined at 780°C, left to stand for 10 minutes, and then the temperature of the melt was lowered to 760°C. Set the inclination angle of the mechanical drum to 45°, the rotational speed to 100r / min, and preheat the inner wall of the drum to 300°C. The refined alloy melt was poured into a mechanical drum at 760°C for rheological treatment, and the treated melt was directly quenched in water for microstructure observation. figure 1 Shown is the microstructure of Al-18Si alloy directly water-quenched without semi-solid treatment, figure 2 It is the microstructure of the alloy rheological slurry after water quenching after being treated by the method of the present invention. From figure 1 , 2 It can be clearly seen that after the treatment of the present invention, the primary silicon size of the Al-18Si alloy is significan...

Embodiment 2

[0042] Al-18Si alloy primary silicon refinement and preparation of rheological slurry. The alloy was melted in a crucible resistance furnace, degassed and refined at 778°C, and allowed to stand for 10 minutes, then the temperature of the melt was lowered to 760°C. Set the inclination angle of the mechanical drum to 10°, the rotational speed to 20 r / min, and preheat the inner wall of the drum to 300°C. The refined alloy melt is poured into a mechanical drum at 760°C for rheological treatment, and the treated melt is directly die-cast to obtain high-silicon aluminum alloy castings.

Embodiment 3

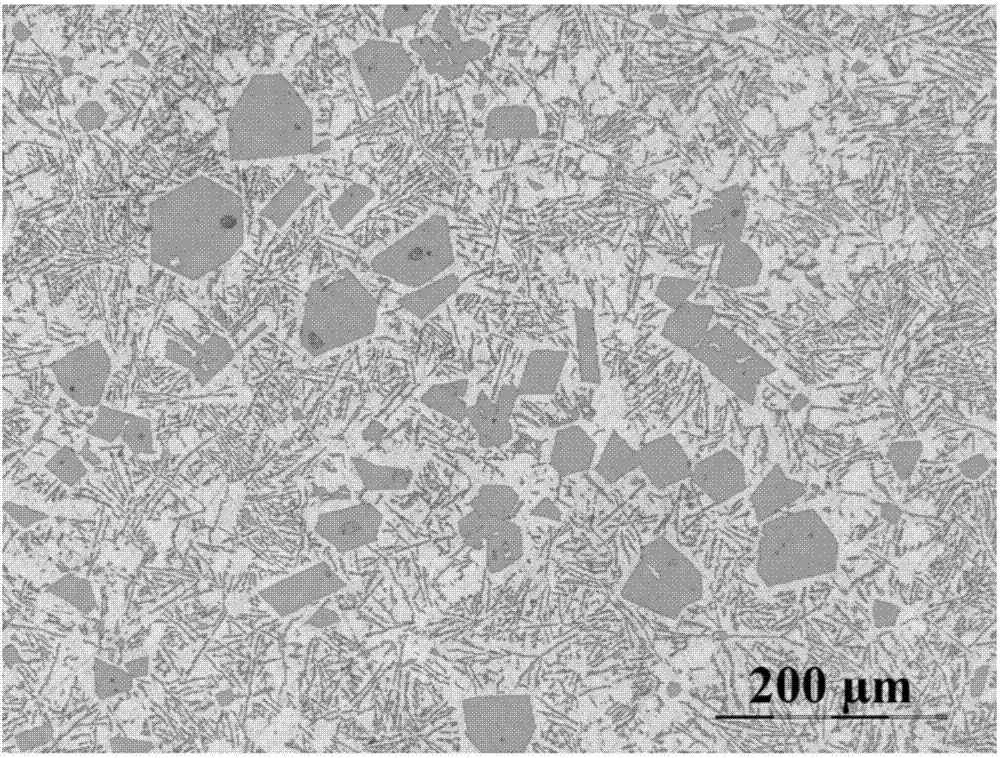

[0044] Al-30Si alloy primary silicon refinement and preparation of rheological slurry. The alloy was melted in a crucible resistance furnace, degassed and refined at 880°C, left to stand for 15 minutes, and then the temperature of the melt was lowered to 860°C. Set the inclination angle of the mechanical drum to 30°, the speed to 30r / min, and preheat the inner wall of the drum to 300°C. The refined alloy melt was poured into a mechanical drum at 860°C for rheological treatment, and the treated melt was directly quenched in water for microstructure observation. image 3 Shown is the microstructure of Al-30Si alloy directly water quenched without semi-solid treatment, Figure 4 It is the microstructure of the alloy rheological slurry after water quenching after being treated by the method of the present invention. From image 3 , 4 It can be clearly seen that after the treatment of the present invention, the primary silicon size of the Al-30Si alloy is significantly refined,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com