Corrugated paper board overturning machine and full-automatic corrugated paper board overturning and staggered-stacking machine

A corrugated cardboard and turning machine technology is applied in the field of corrugated cardboard turning machines and automatic corrugated cardboard turning and dislocation stacking machines, which can solve the problems of poor turning effect of corrugated cardboard and low working efficiency, and achieve high working efficiency, compact structure, Use good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

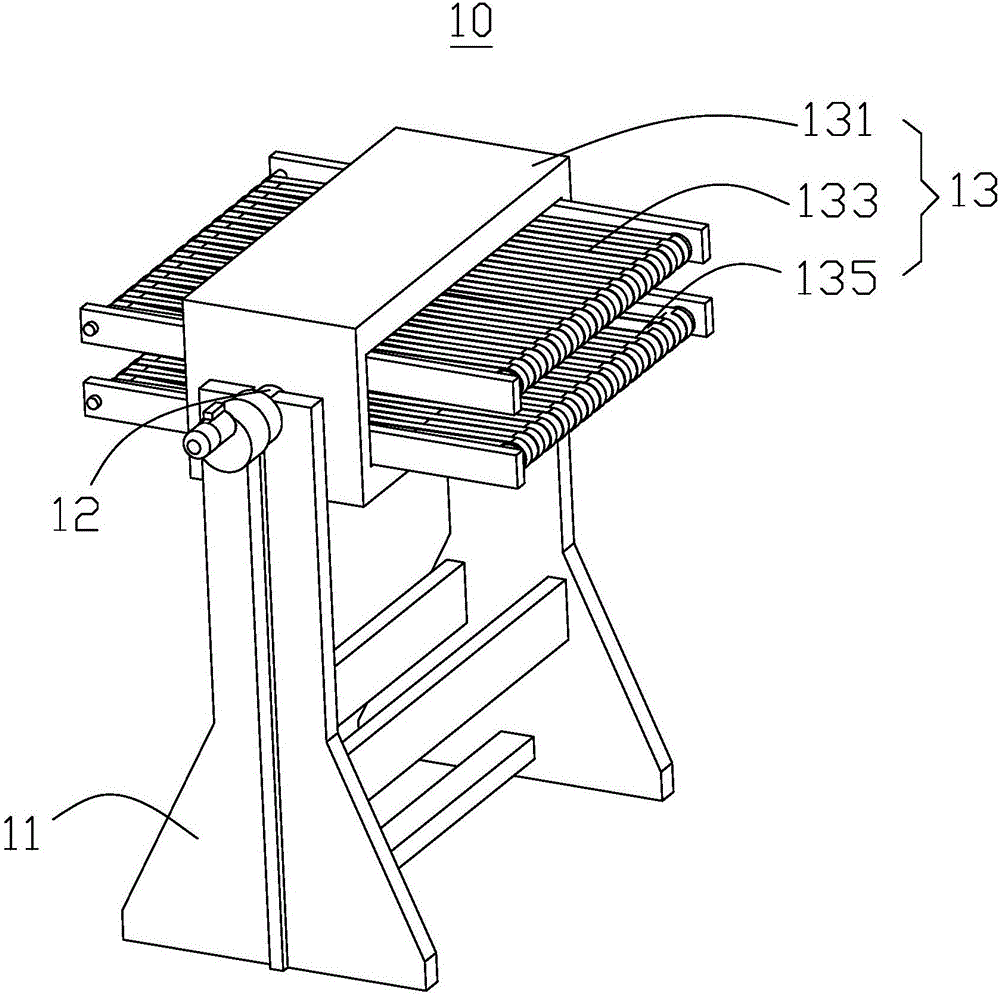

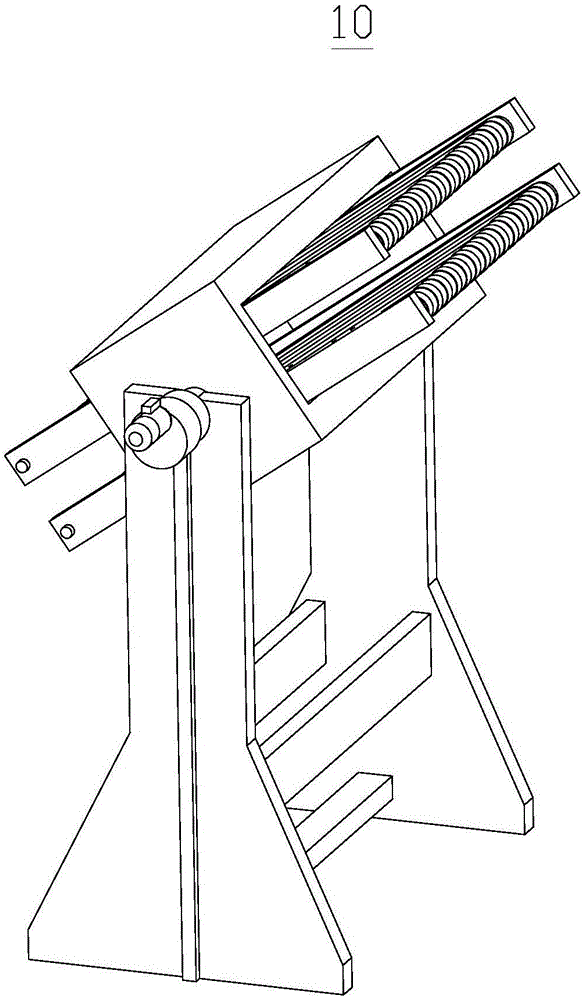

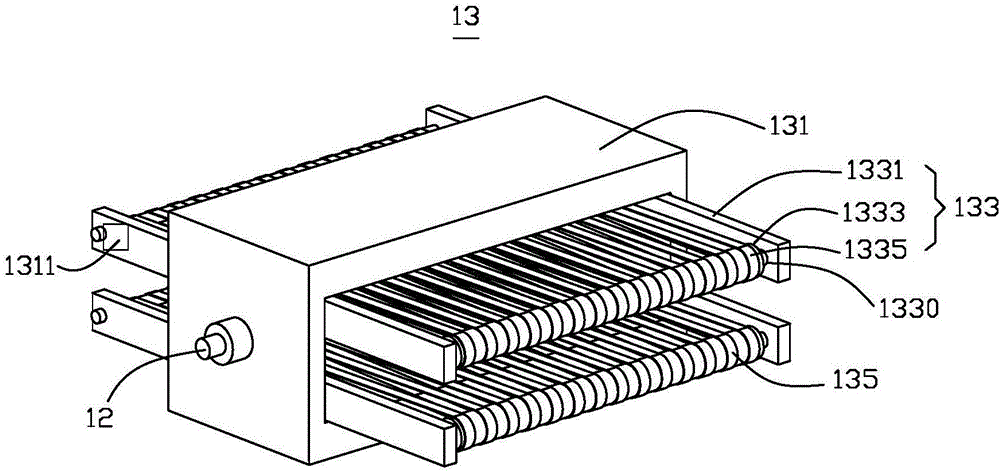

[0036] Please refer to figure 1 , the present embodiment provides a corrugated cardboard turning machine 10, which includes a frame 11 and a turning assembly 13, the turning assembly 13 includes a turning body 131 and two transport parts, the turning body 131 is rotatably connected to the first rotating shaft 12 The frame 11 and the transportation part are slidably connected to the turning body 131 along the radial direction of the first rotating shaft 12, and the two transportation parts can approach or move away from each other.

[0037] What needs to be explained here is that the transportation part includes a first transportation part 133 and a second transportation part 135. When introducing the transportation parts below, only the first transportation part 133 is introduced, and the structure of the second transportation part 135 can refer to the first transportation part 133. . During installation, the rack 11 is often installed on the ground.

[0038] Please refer to...

Embodiment 2

[0078] Please refer to Figure 5 , this embodiment also provides a corrugated cardboard turning machine 10, the technical solution described in embodiment 1 is also applicable to this embodiment, and the disclosed technical solution in embodiment 1 will not be described again.

[0079]Specifically, the difference between this embodiment and Embodiment 1 is that the elastic buffer also includes a second elastic buffer 1339, one end of the second elastic buffer 1339 is connected to the end of the rotation hole 13311 close to the transport channel, and the second elastic buffer The other end of piece 1339 is connected with transfer piece 1337.

[0080] Such as Figure 5 As shown, the transfer member 1337 is located between the first elastic buffer member 1338 and the second elastic buffer member 1339. Under the action of the two buffer members, the transfer member 1337 has a good buffering effect when moving up and down relative to the rotation hole 13311. In the case of ensuri...

Embodiment 3

[0082] This embodiment also provides a fully automatic stacker for overturning and dislocation of corrugated cardboard, which includes the above-mentioned overturning machine for corrugated cardboard 10, and the structure of the overturning machine for corrugated cardboard 10 can refer to the embodiment 1 or 2, the fully automatic corrugated cardboard turning and dislocation stacking machine has all the functions of the corrugated cardboard turning machine 10.

[0083] In summary, the present invention provides a corrugated cardboard turning machine 10. The corrugated cardboard turning machine 10 has the function of automatically turning over the corrugated cardboard, and the corrugated cardboard is transported from one end of the transportation channel by the relative separation of the two transport parts. To the other end, and then through the relative close clamping of the two transport parts, the corrugated cardboard is clamped and turned over to realize the effect of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com