Noodle cooker and noodle cooking equipment

A noodle cooking machine and noodle water technology, applied in cooking utensils, household utensils, applications, etc., can solve the problems of low degree of automation, poor use effect, manual operation, etc., and achieve good taste of noodles, low energy consumption, and automation high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

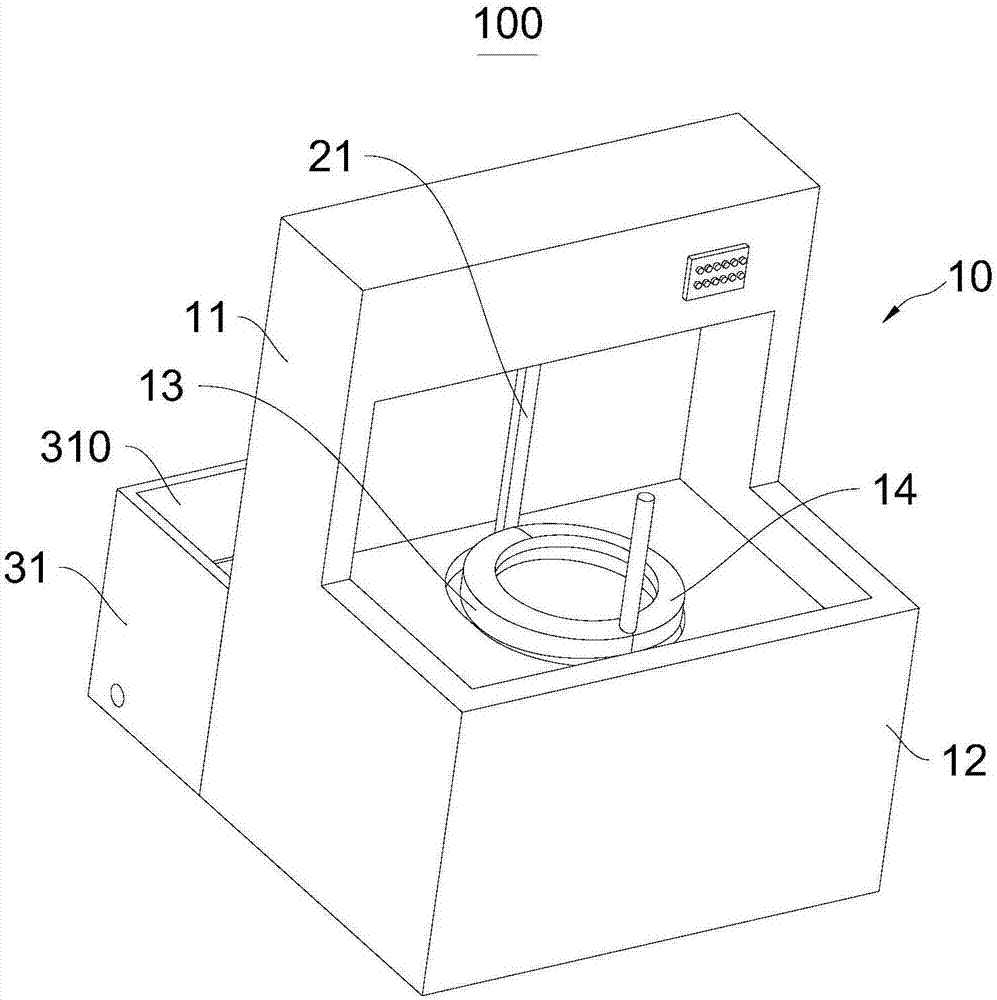

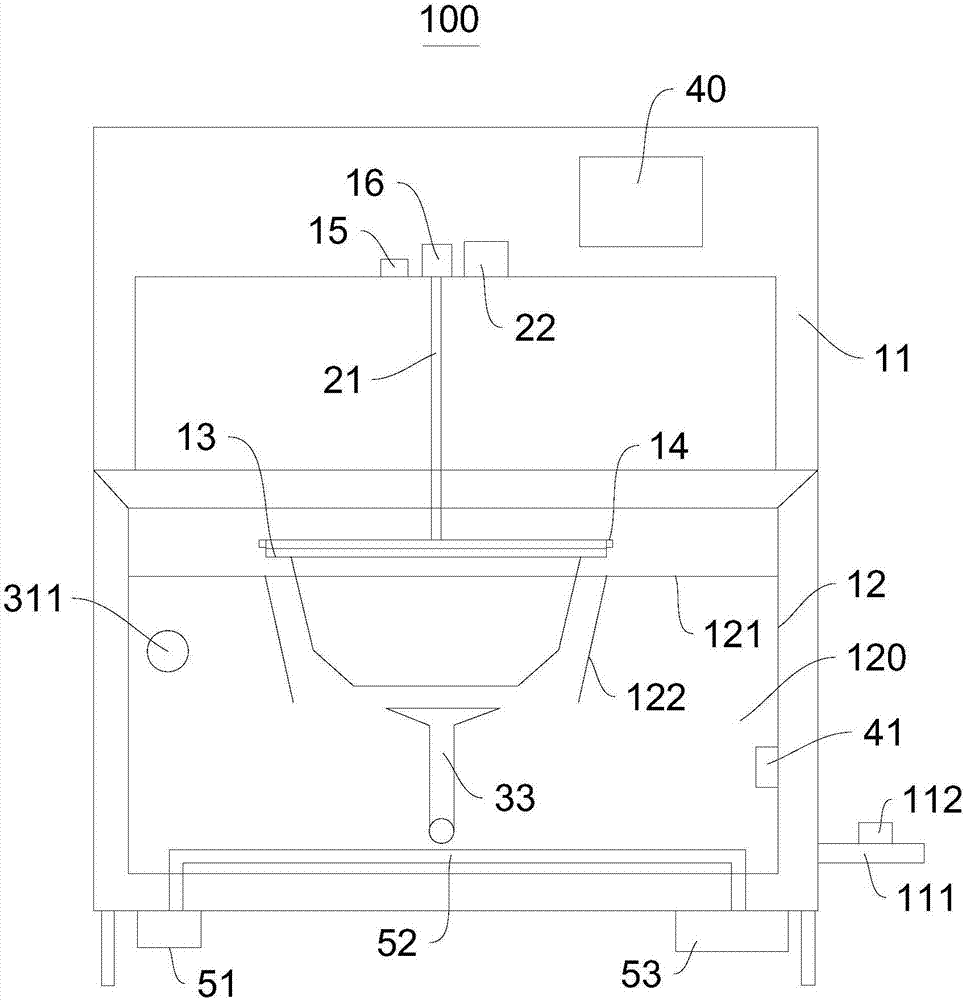

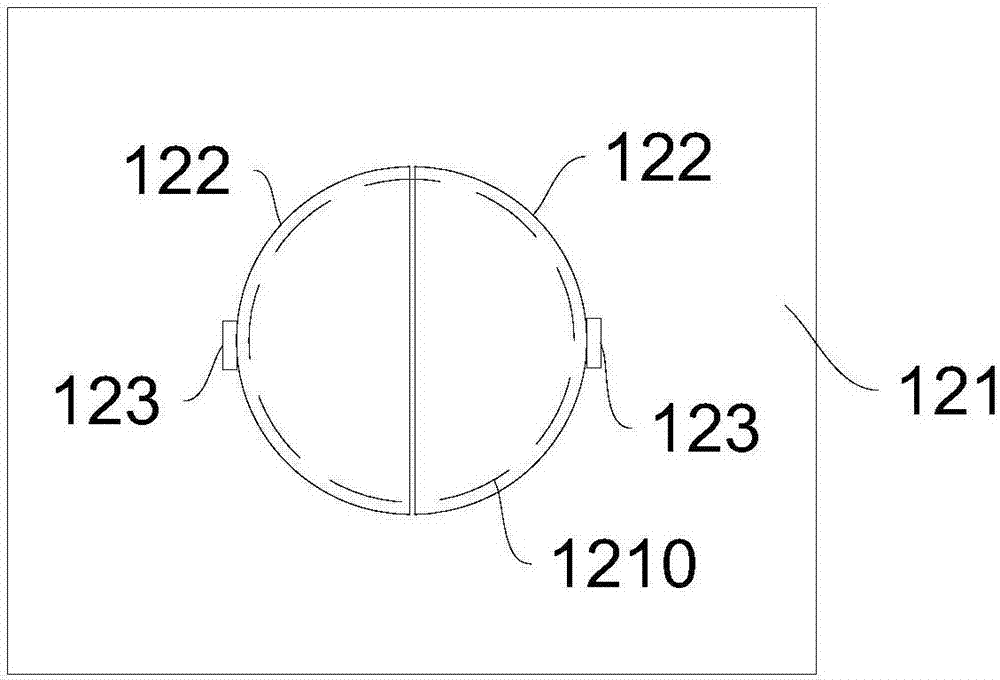

[0049] Please refer to figure 1 and figure 2 , the present embodiment provides a noodle cooker 100, the noodle cooker 100 includes a noodle cooker 10 and a pot body 12, the pot body 12 has a first accommodating cavity 120 for cooking noodles, and the first accommodating cavity 120 can store Noodle water for cooking noodles.

[0050] The noodle cooker 10 includes a body 11 connected to a pot body 12 .

[0051] The noodle cooker 10 also includes a lifting system. The lifting system includes a noodle drain bracket 13, a noodle drain 14, a push rod 21 and a driving device 22. The noodle drain bracket 13 is used for erecting the noodle drain 14, and the noodle drain 14 is used for loading noodles. The surface drain bracket 13 is detachably connected to one end of the push rod 21, the push rod 21 is slidably connected to the body 11, and the driving device 22 is used to drive the push rod 21 to slide. When the push rod 21 slides, the noodle drain bracket 13 approaches or moves a...

Embodiment 2

[0098] Please refer to Figure 15 , this embodiment also provides a noodle cooker 100, the technical solution described in embodiment 1 is also applicable to this embodiment, and the disclosed technical solution in embodiment 1 will not be described again.

[0099] Specifically, the difference between this embodiment and embodiment 1 is that the rotating part 1532 of the first abutting member 153 in embodiment 1 is located between the abutting part 1531 and the action part 1533, and the first abutting part 153 in embodiment 2 The abutting portion 1531 of the member 153 is located between the rotating portion 1532 and the acting portion 1533 .

[0100] In Embodiment 1, the push rod 21 has a sliding channel, that is, an area that slides up and down, and the first contact 152 is located on the side of the first switch body 151 away from the sliding channel, that is, opposite to the sliding channel. Figure 11 In terms of the middle position, the first contact 152 is located on t...

Embodiment 3

[0104] Please refer to Figure 16 , this embodiment also provides a noodle cooker 100, the technical solution described in embodiment 1 is also applicable to this embodiment, and the disclosed technical solution in embodiment 1 will not be described again.

[0105] Specifically, the difference between this embodiment and Embodiment 1 is that the first switch body 151 included in the first switch 15 is a normally closed micro switch.

[0106] The first contact 152 of the first switch body 151 is set downward, and the abutting portion 1531 of the first abutting member 153 is located between the rotating portion 1532 and the action portion 1533. When the action portion 1533 moves downward, the abutment portion 1531 rotates clockwise and away from the first contact 152 , when the action part 1533 moves upward, the abutting part 1531 rotates counterclockwise and abuts against the first contact 152 .

[0107] The first switch 15 also includes a first return member 154, one end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com