Polymethacrylimide foam plastic and preparation method thereof

A technology of acrylimide and foamed plastics, applied in the field of polymer materials, can solve the problems of many low-molecular residues, large difference in reactivity ratio, and large heat of polymerization, so as to reduce low-molecular residues and prevent explosive polymerization. , the effect of improving the degree of cross-linking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

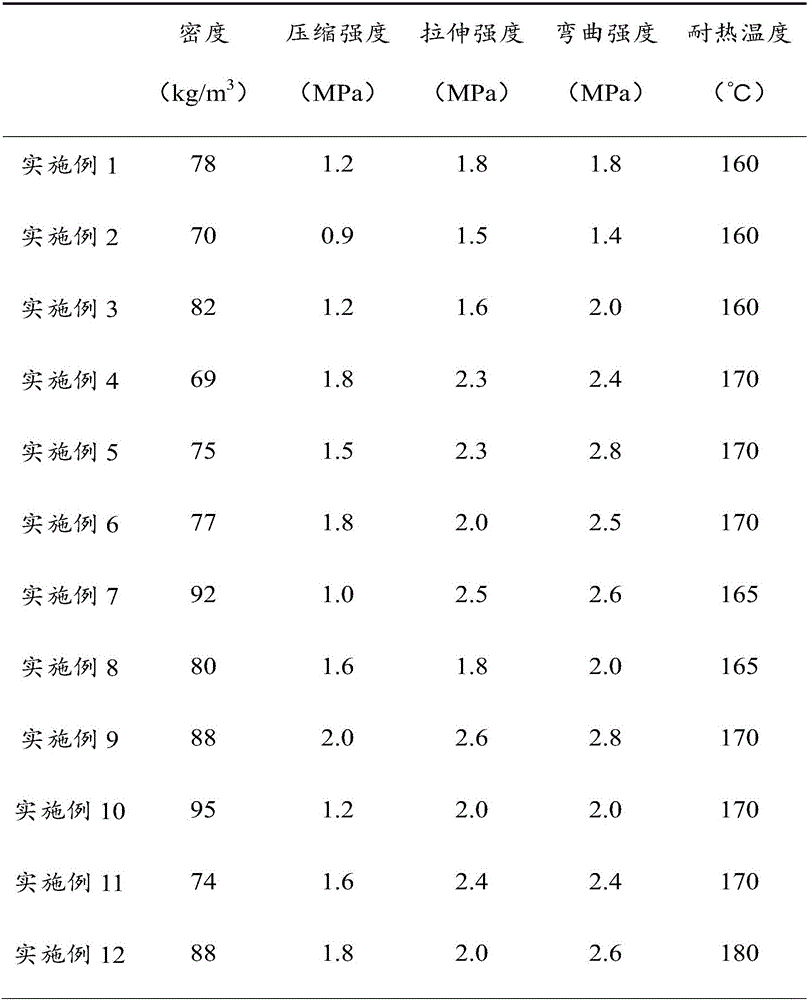

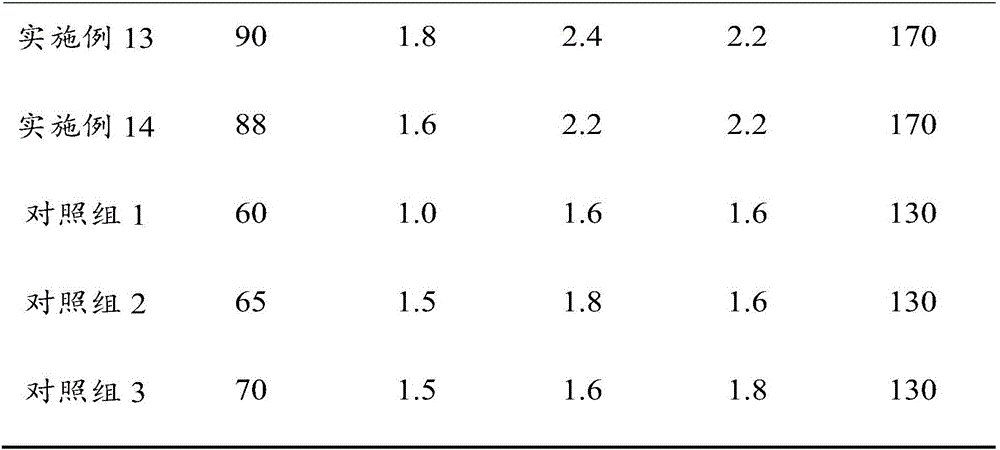

Examples

Embodiment 1

[0035] Take by weight 150 parts of acrylonitrile, 20 parts of methacrylic acid, 0.8 part of acrylamide, 15 parts of phenylmaleimide, 0.04 part of azobisisoheptanonitrile, dibenzoyl peroxide, peroxide 0.6 part of mixture of lauryl oxide and peroxydicarbonate, 6 parts of allyl acrylate, 25 parts of N,N-dimethylformamide, 0.2 part of carboxamide, 1 part of polyethylene wax, diaryl alkyl phosphate 0.2 part of base ester. Add the above raw materials into the reaction kettle, mix them and pour them into a mold with a cavity inside, and pre-polymerize at 20°C to obtain a mixed solution; then put the mixed solution in a water bath at 30°C for 90 hours, and then bake it at 70°C Polymerize for 9 hours, cool and demould to obtain a copolymerized plate; heat the copolymerized plate at 80°C for 4 hours to obtain the primary product; Foaming for the first time for 1 hour and foaming for the second time for 1 hour, and then curing at 160°C for 2 hours to obtain poly(meth)acrylimide foam.

Embodiment 2

[0037] Weigh 30 parts by weight of acrylonitrile, 20 parts of methacrylic acid, 0.1 part of methacrylamide, 4 parts of methylmaleimide, 0.8 part of azobisisobutyronitrile, dibenzoyl peroxide , 0.04 parts of a mixture of lauryl peroxide and tert-butyl peroxybenzoate, 0.05 parts of 2-methallyl acrylate, 0.8 parts of a mixture of ethanol and propanol, 0.4 parts of formamide, and 0.3 parts of silicone compounds , 0.2 parts of conductive carbon black. Add the above raw materials into the reaction kettle, mix them and pour them into a mold with a cavity inside, and pre-polymerize at 50°C to obtain a mixed solution; then put the mixed solution in a water bath at 40°C for 40 hours, and then bake it at 90°C Polymerize for 7 hours, cool and demould to obtain a copolymerized plate; heat the copolymerized plate at 120°C for 2 hours to obtain the primary product; Carry out the first foaming for 0.2h and the second foaming for 0.2h, and then aging at 170°C for 0.2h to obtain poly(meth)acry...

Embodiment 3

[0039] Weigh 120 parts by weight of acrylonitrile, 150 parts of methacrylic acid, 6 parts of itaconic acid, 0.1 part of tribromophenylmaleimide, 4 parts of azobisisovaleronitrile, lauryl peroxide , 8 parts of a mixture of peroxydicarbonate and tert-butyl peroxybenzoate, 2 parts of allyl methacrylate, 3 parts of a mixture of formamide and isopropanol, butanol, 5 parts of methacrylamide, high 8 parts of polytetrafluoroethylene, 3 parts of calcium powder, 3 parts of dimethyl methylphosphonate, 5 parts of fatty acid surfactant, 0.1 part of water glass, and 0.01 part of benzoquinone. Add the above raw materials into the reaction kettle, mix them and pour them into a mold with a cavity inside, and pre-polymerize at 30°C to obtain a mixed solution; then put the mixed solution in a water bath at 35°C for 50 hours, and then bake it at 80°C Polymerize for 8 hours, cool and demould to obtain a copolymerized plate; heat the copolymerized plate at 100°C for 3 hours to obtain the primary pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com