Component Imaging Device, And Component Mounting Device Equipped With Component Imaging Device

A camera device and camera unit technology, which is applied in the field of component mounting devices and component camera devices, and can solve problems such as difficult to capture projected images of components, difficult to capture and maintain image quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

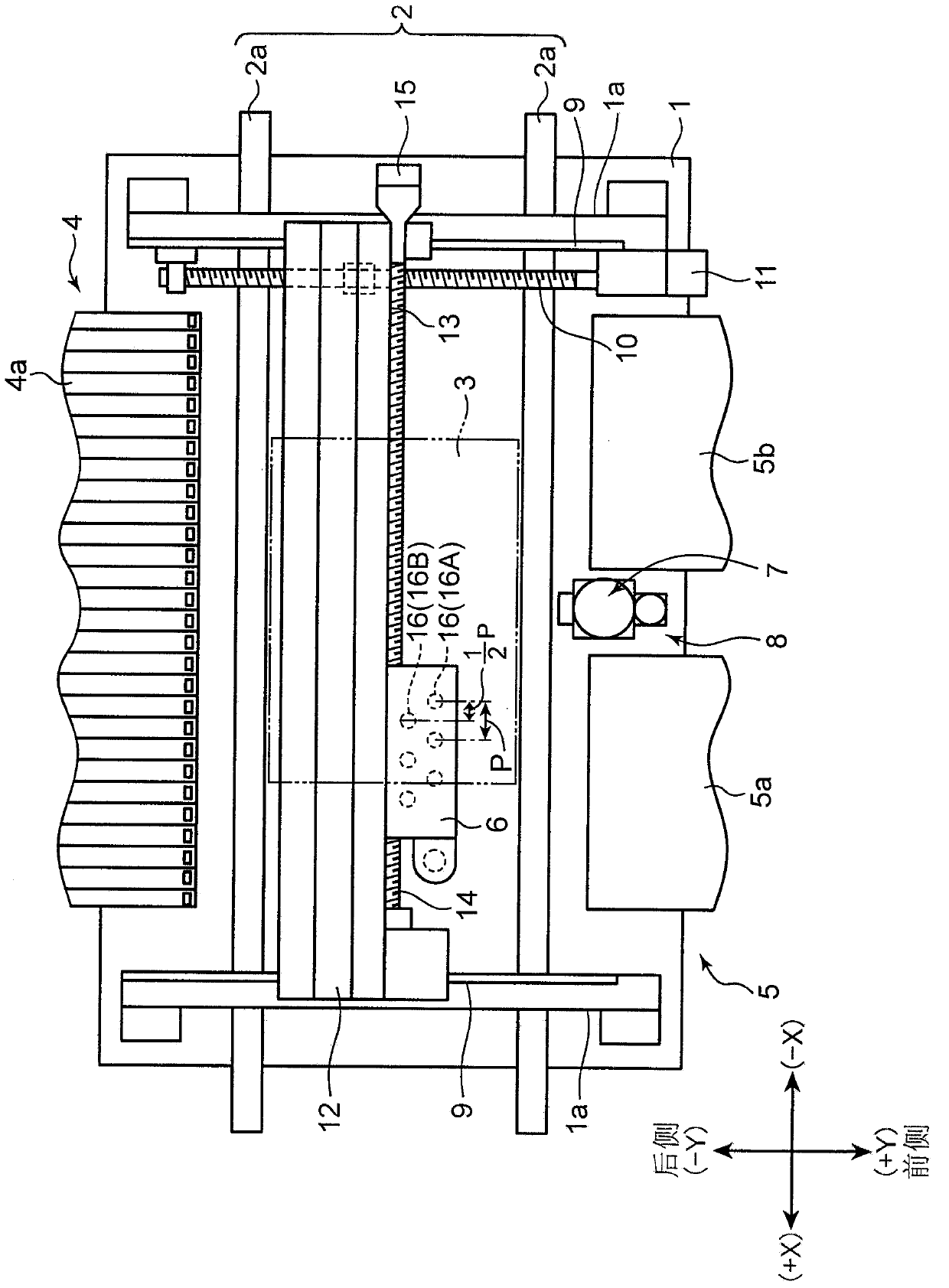

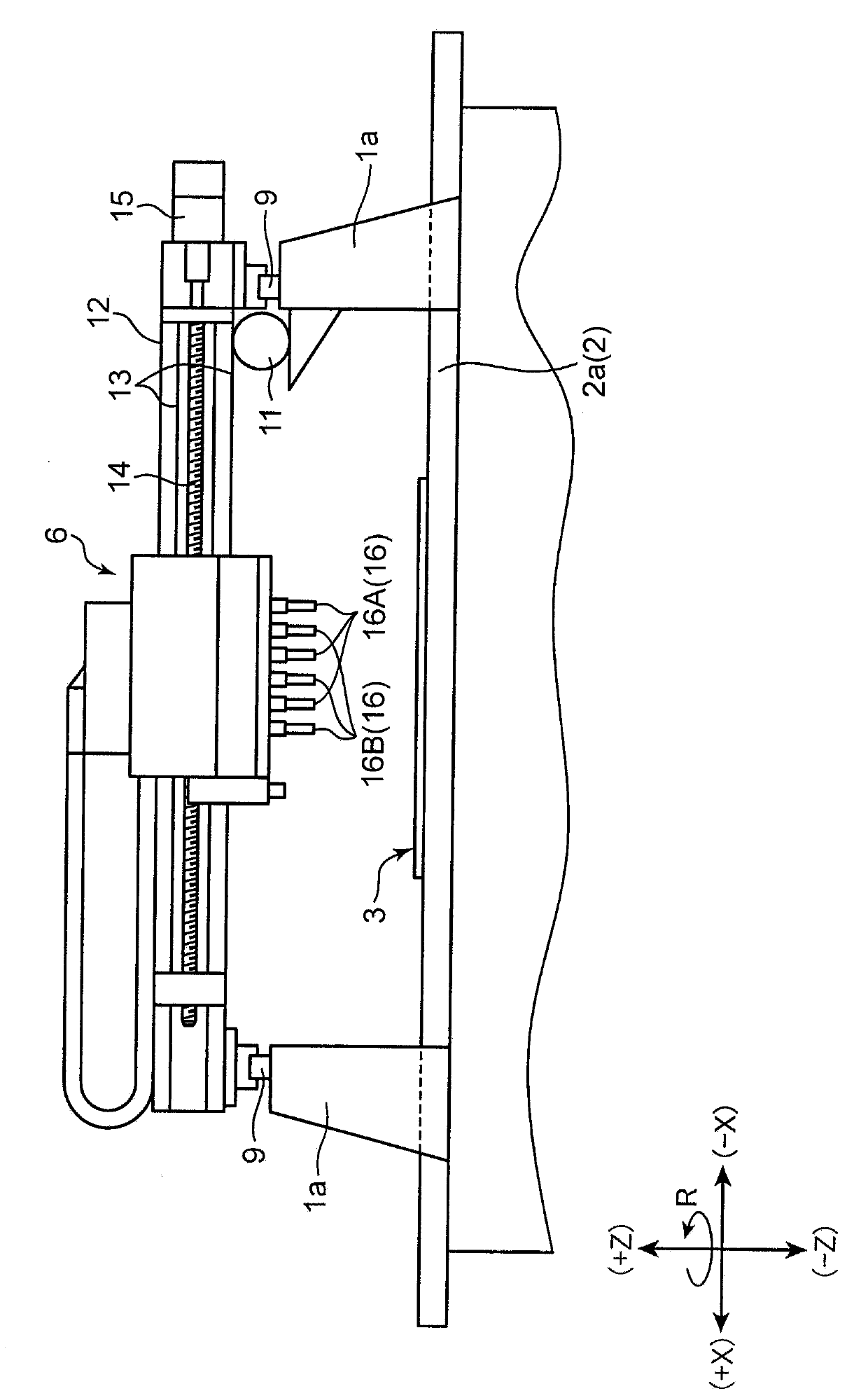

[0030] figure 1 and figure 2 The component mounting apparatus (component mounting apparatus equipped with the component imaging device of this invention) which concerns on this invention is shown schematically. figure 1 for top view, figure 2 It is a front view and schematically shows each component mounting device. exist figure 1 , figure 2 In the drawings described below, XYZ rectangular coordinate axes are shown to clarify the directional relationship.

[0031] The component mounting apparatus includes: a base 1; a substrate transport mechanism 2 provided on the base 1 and transporting a substrate 3 such as a printed wiring board (PWB) in the X direction; component supply parts 4 and 5; With the head unit 6 ; a head unit drive mechanism that drives the head unit 6 ; a component imaging unit for recognizing a holding component of the head unit 6 , and the like.

[0032] The substrate transport mechanism 2 includes a pair of transport belts 2 a , 2 a for transporting...

no. 2 Embodiment approach

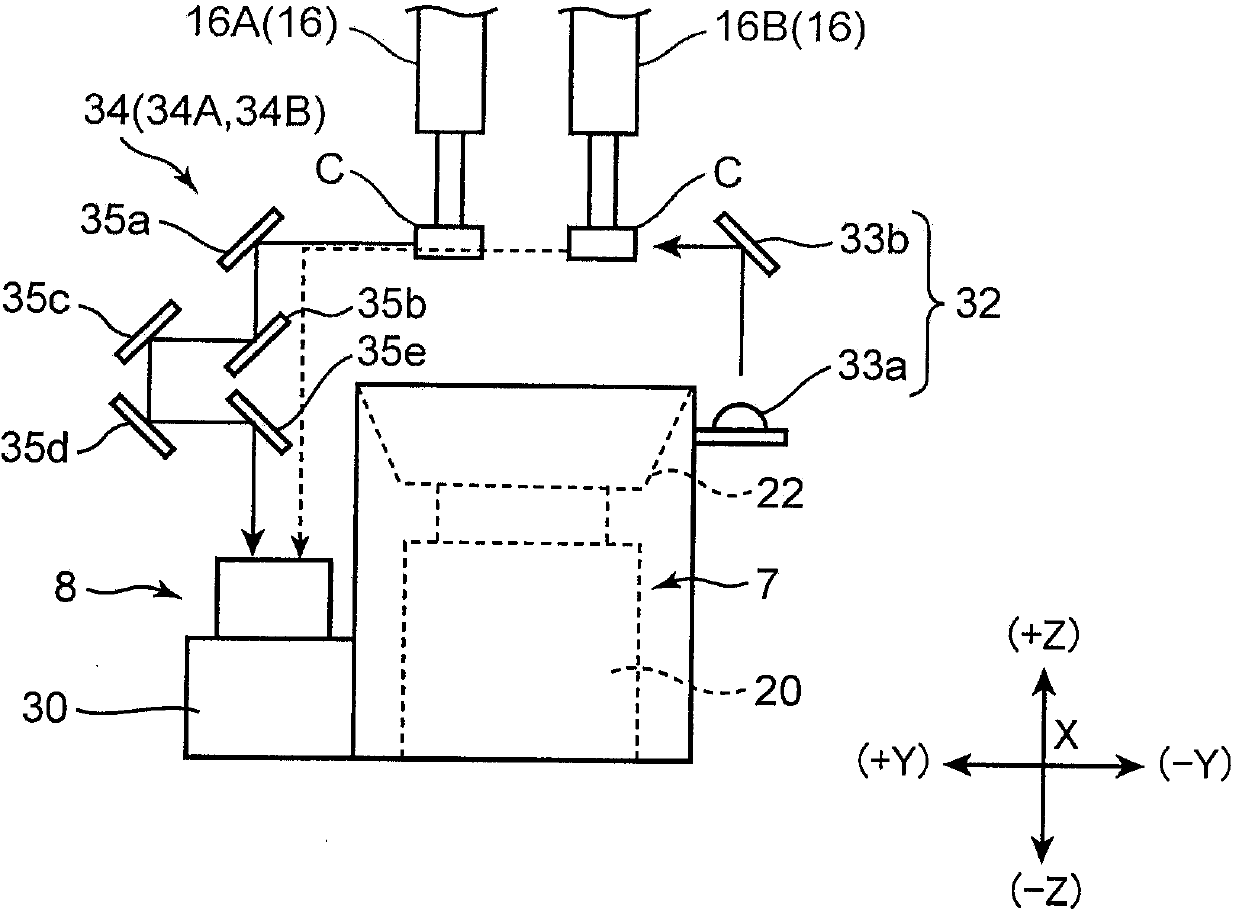

[0061] Figure 7 and Figure 8 The component imaging unit in the component mounting apparatus which concerns on 2nd Embodiment is shown schematically. The configuration of the second component imaging unit 8 of this component mounting device differs from the first embodiment in the following points, and other configurations are basically common to the component mounting device of the first embodiment. Therefore, in the following description, the same reference numerals will be attached to the parts common to the first embodiment, and the description will be omitted, and the differences from the first embodiment will be mainly described in detail.

[0062] The illuminating unit 32 of the second element imaging unit 8 according to the second embodiment includes: a first light source 333a for irradiating illumination light with a first wavelength; and a second light source 333b for irradiating illumination with a second wavelength different from the first wavelength. Light. Th...

no. 3 Embodiment approach

[0071] Figure 9 and Figure 10 The component imaging unit in the component mounting apparatus which concerns on 3rd Embodiment is shown schematically. The structure of the second component imaging unit 8 of the structure of this component mounting device differs from the first embodiment in the following points, and the other structures are basically common to the component mounting device of the first embodiment. Therefore, in the following description, the same reference numerals will be attached to the parts common to the first embodiment, and the description will be omitted, and the differences from the first embodiment will be mainly described in detail.

[0072] The second component imaging unit 8 of this third embodiment has a camera 30 including a CCD line sensor (referred to as a line sensor 31 ). The camera 30 is installed in such a manner that the imaging elements are arranged in the Y direction, and sequentially captures the projection image of one line of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com