Boiler furnace safety net

A boiler furnace and safety net technology, which is applied in the field of safety nets, can solve the problems of not being able to quickly open and restore the safety nets, consume a lot of labor, and have a large height difference between up and down, so as to ensure hoisting efficiency and safety protection requirements, and shorten the safety net. Protects against blank time, easy to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

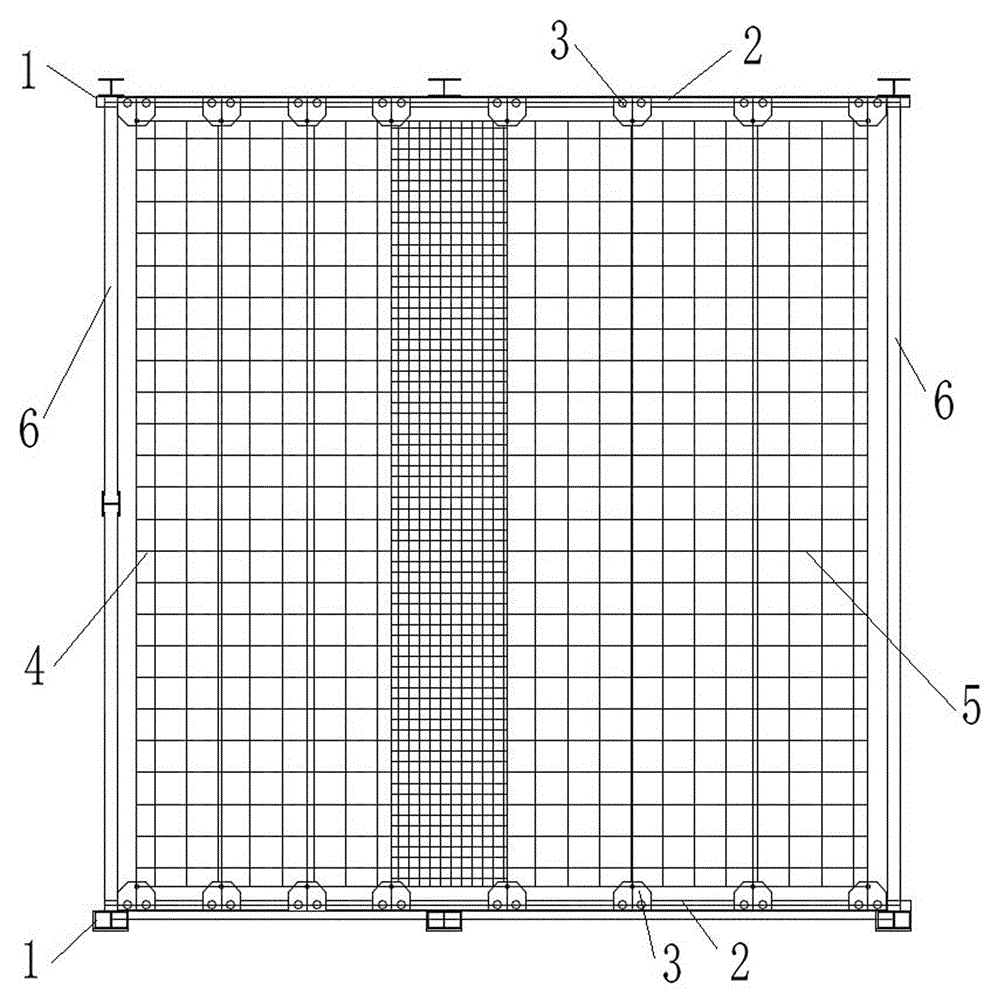

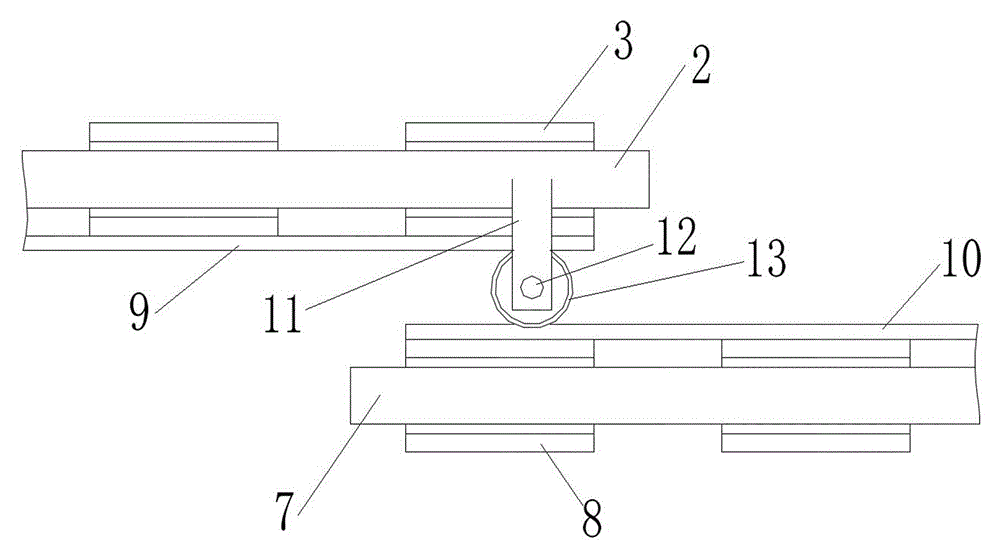

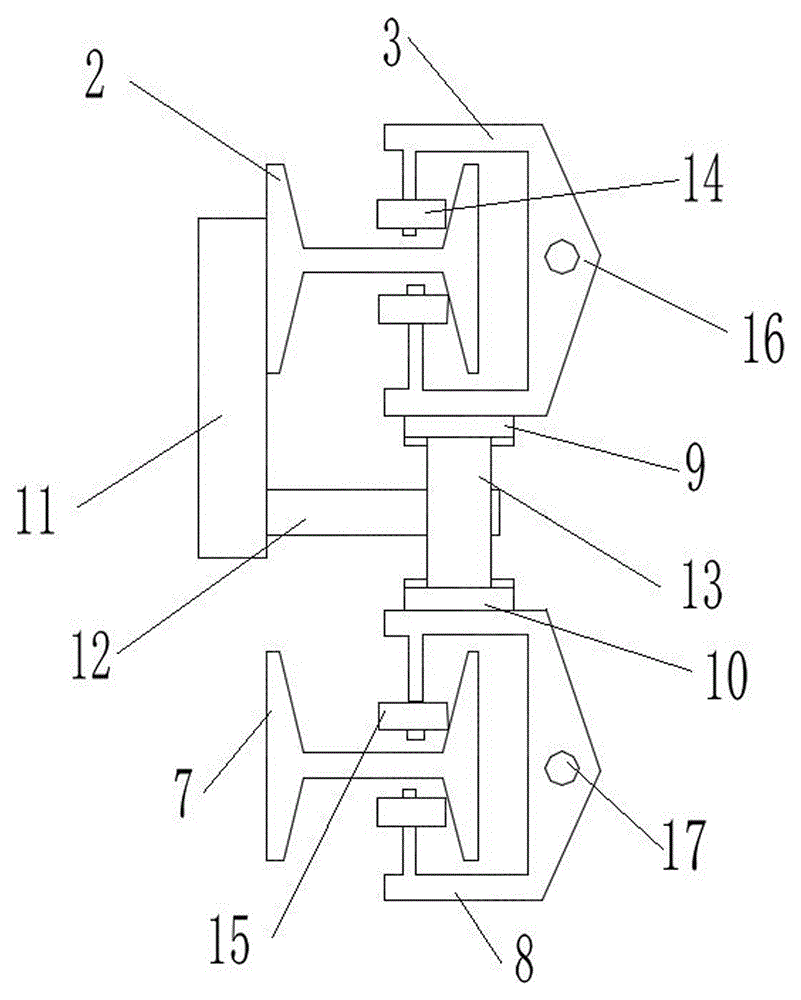

[0016] Attached below figure 1 to attach Figure 4 The present invention will be further described.

[0017] as attached figure 1 As shown, the boiler furnace safety net includes two upper slide rails 2 installed on the front and rear ends of the furnace steel structure 1 parallel to each other and on the same horizontal plane, and installed on the furnace steel structure. Two lower rails 7 below the first slide rail 2, some upper tackles 3 that are slidably installed on the two upper slide rails 2 through rollers I 14, and some sliding carriages 3 that are slidably installed on the two lower rails 7 through rollers II 15 Car 8, the upper block 3 is provided with a hanging hole I 16, the lower block 8 is provided with a hanging hole II 17, the steel wire rope on the edge of the upper safety net 4 is tensioned and installed on the upper block 3 on both sides through the hanging hole I 16 , the wire rope on the edge of the lower safety net 5 is tensioned and installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com