Furnace door opening-closing device for flat-opening type quenching furnace

A technology of opening and closing devices and quenching furnaces, which is applied in the direction of quenching devices, heat treatment equipment, manufacturing tools, etc., can solve the problems of low safety performance of manual operation, accidental injuries of workers, and high labor intensity, etc., and achieve good exercise effects, labor saving, The effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

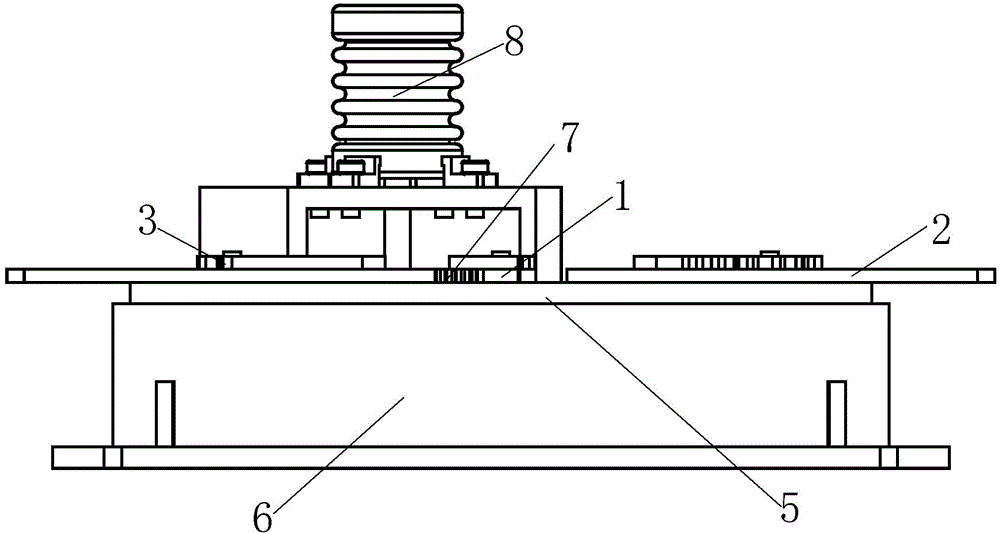

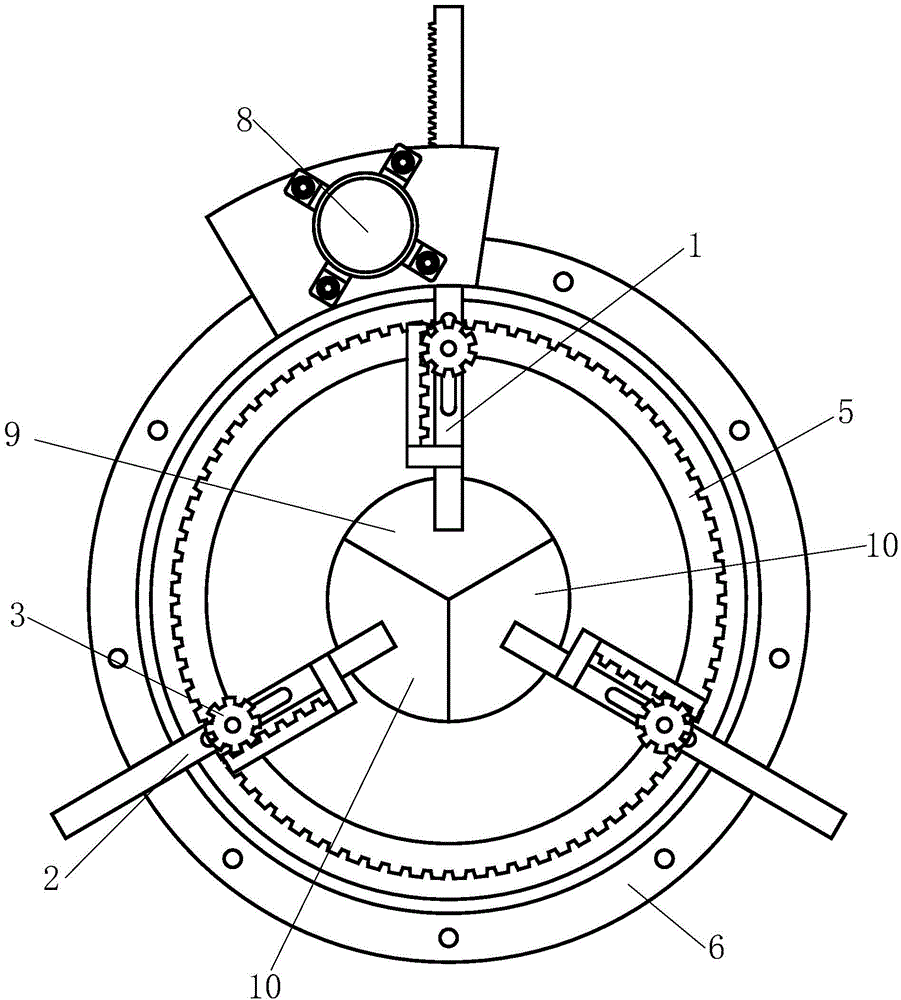

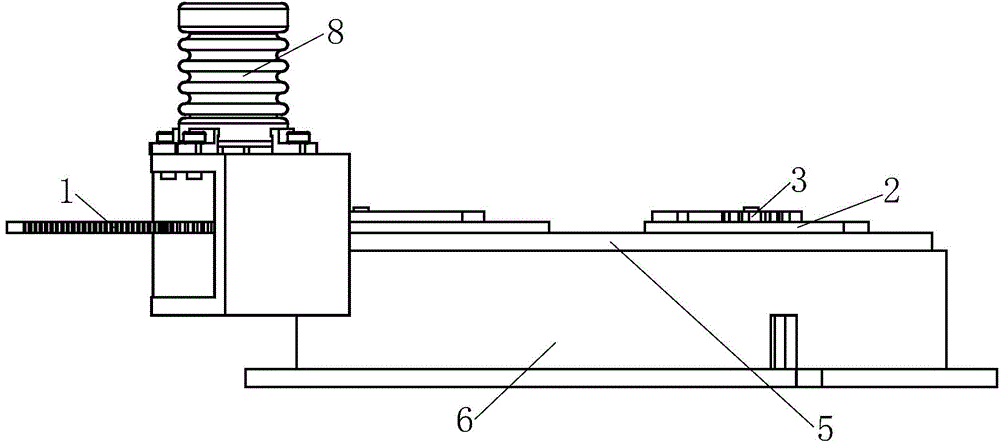

[0028] Such as Figure 1 to Figure 8 As shown, a swing-type quenching furnace door opening and closing device includes a base 6, a driving element 8 and an actuator. The see-through ring 604, the rolling ball 605, the central connecting frame 606 and the outer connecting column 607, the fan-shaped connecting plate 602 is fixed on the lower side of the ring fixing ring 601, and the U-shaped connecting seat 603 is fixed on the ring fixing ring The upper part of the edge of 601, the central see-through ring 604 coincides with the axis of the ring fixed ring 601, the central connecting frame 606 is symmetrical to the circular center of the central see-through ring 604, and one end of the central connecting frame 606 is connected to the center The outer ring of the material-penetrating ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com