High-tenacity optical fiber steel wire rope

A steel wire rope and high toughness technology, applied in the field of steel wire ropes, can solve the problems of wire rope breakage and insufficient toughness, and achieve the effect of good buffering and toughness enhancement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

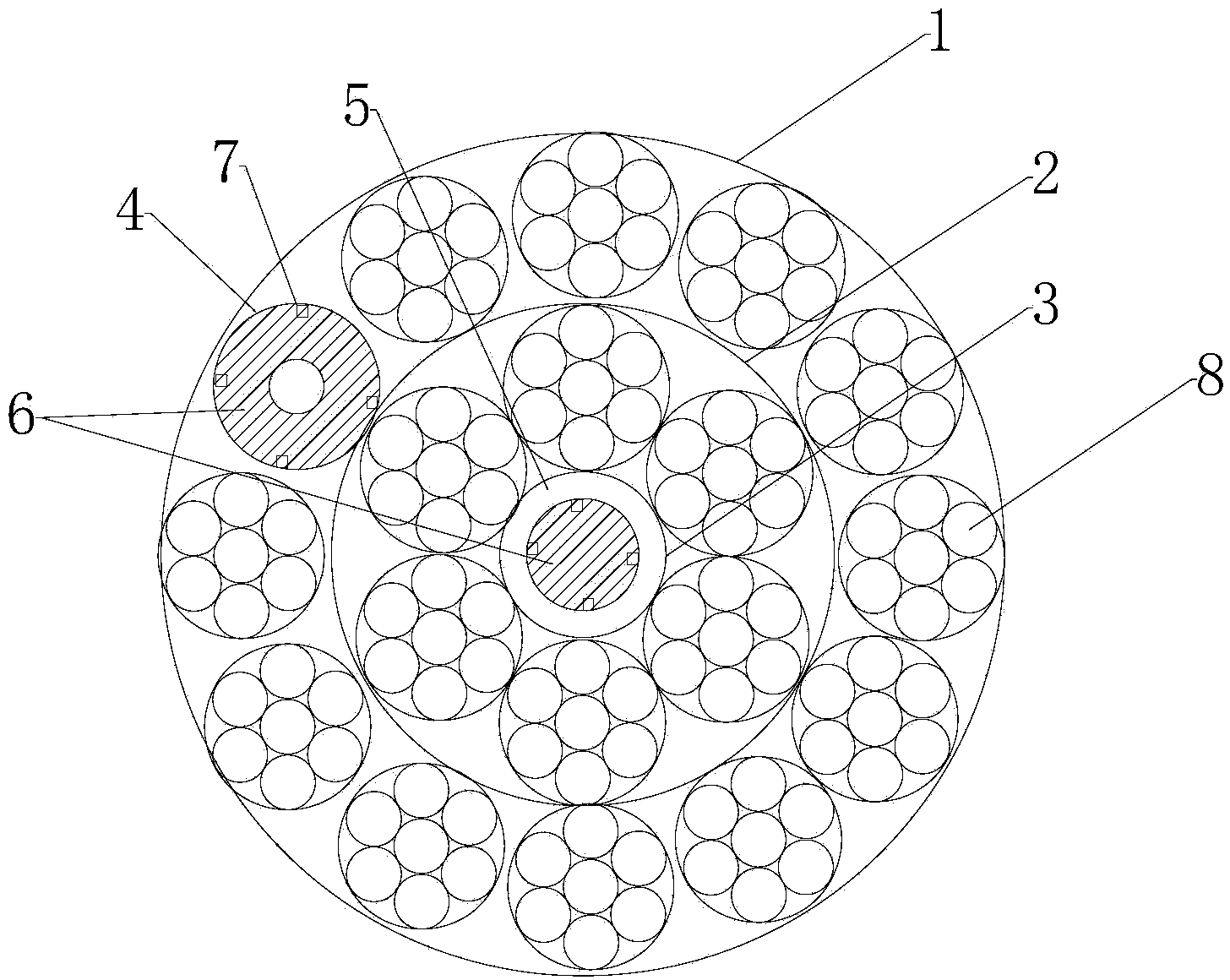

[0018] Combine below figure 1 The technical solutions of the present invention are further described through specific implementation methods.

[0019] figure 1 It is a structural diagram of a high tenacity optical fiber steel wire rope provided by the specific embodiment of the present invention.

[0020] A high-tenacity optical fiber steel wire rope, comprising an outer layer strand 1, an inner layer strand 2, a central strand 3 and an optical fiber strand 4, the outer layer strand 1 and the inner layer strand 2 are all twisted by several strands, and the strands The rope is twisted by a strand core and a strand surface, and the optical fiber strand 4 is arranged at any strand position in the outer layer strand 1, and the central strand 3 includes a hollow steel wire body 5, and the hollow steel wire body 5 The interior is filled with adhesive parts 6, the optical fiber strand 4 includes a casing and an optical fiber bundle, and the adhesive part 6 is filled between the cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com