A Gravity Breaker

A breaking hammer and gravity-type technology, which is applied to earth movers/excavators, construction, etc., can solve the problems of large occupied area, complex structure, and low impact capacity of vertical poles, and achieve high work efficiency, simple design structure, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

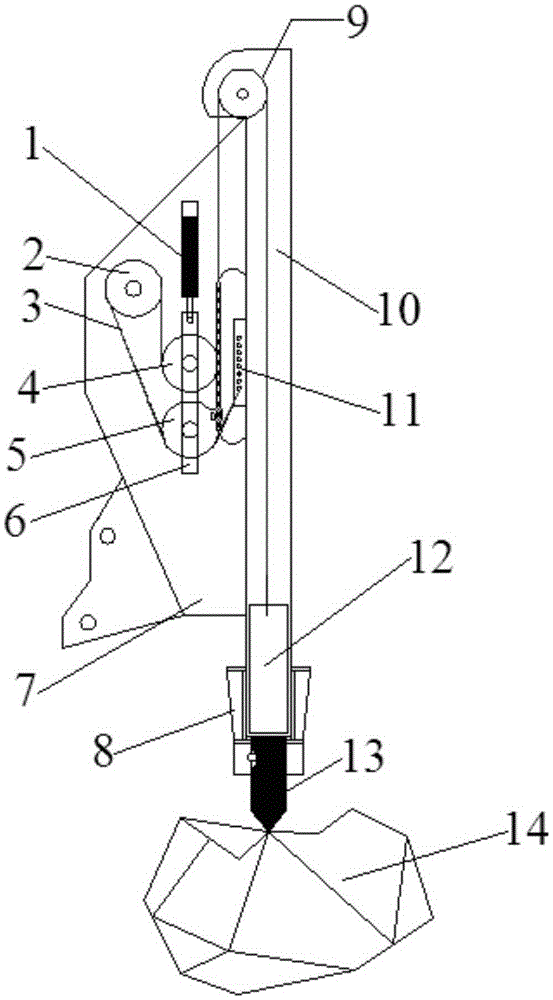

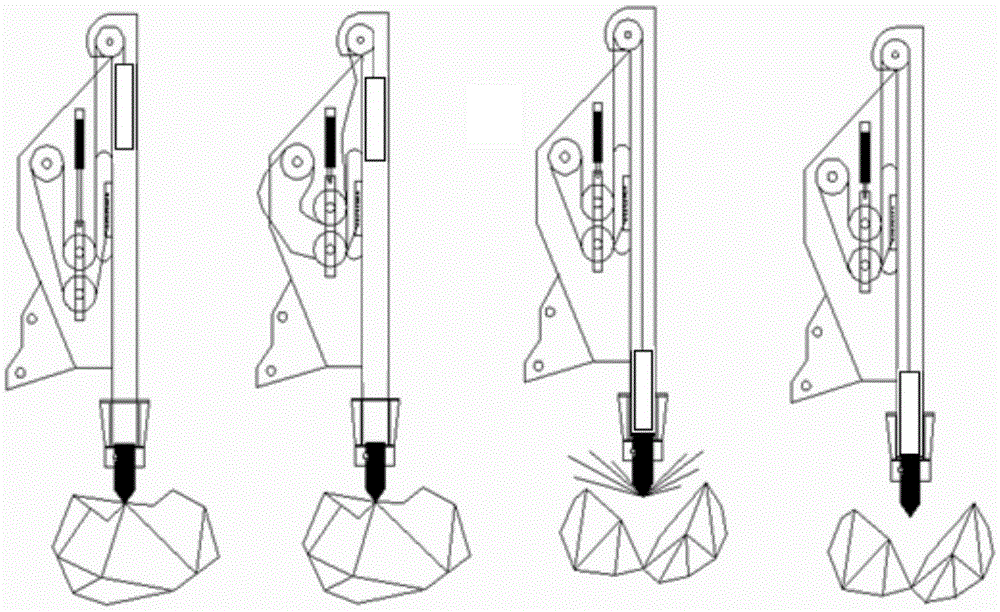

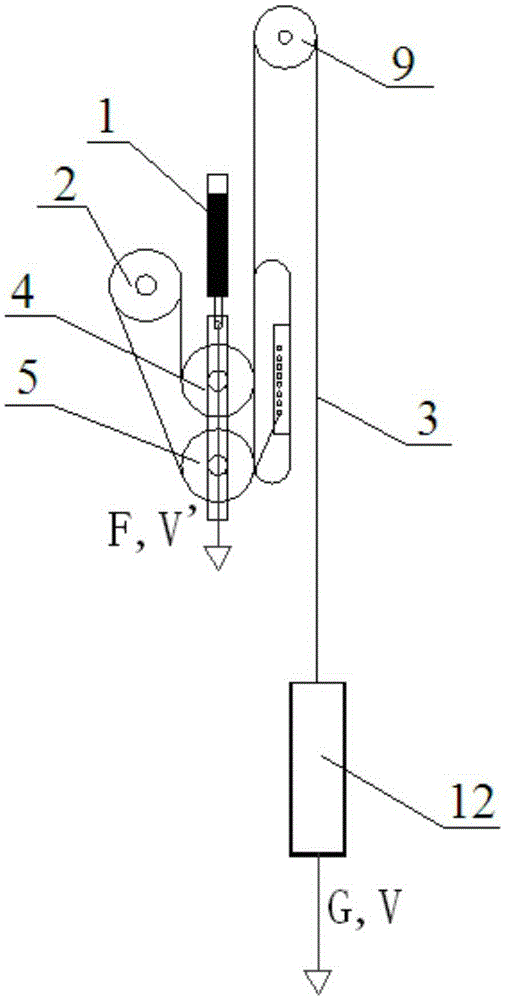

[0027] A gravity breaker, such as figure 1 As shown, the hammer body shell 7 is included, the hammer body shell 7 is provided with a hydraulic cylinder 1 and a pulley transmission mechanism, one side of the hammer body shell 7 is provided with a guide cylinder 10, the top of the guide cylinder 10 is provided with a top pulley 9, and the guide cylinder The lower end of 10 is provided with a drill rod 13, and an impact hammer 12 is provided inside the guide cylinder 10. The upper end of the impact hammer 12 is connected to the head end of the steel wire rope 3, and the tail end of the steel wire rope 3 is fixed on the hammer after bypassing the top pulley 9 and the pulley transmission mechanism in turn. On the body shell 7, the hydraulic cylinder 1 is connected with the pulley transmission mechanism. A series of several adjustment holes 11 are provided on the hammer shell 7 . The bottom end of the guide cylinder 10 is connected with a buffer shock absorbing ring 8, the upper ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com