Gas cylinder safety supervision system and method

A monitoring system and gas cylinder technology, applied in the field of communications, can solve the problems of gas mixing, low efficiency, hidden safety hazards, etc., and achieve the effect of avoiding mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

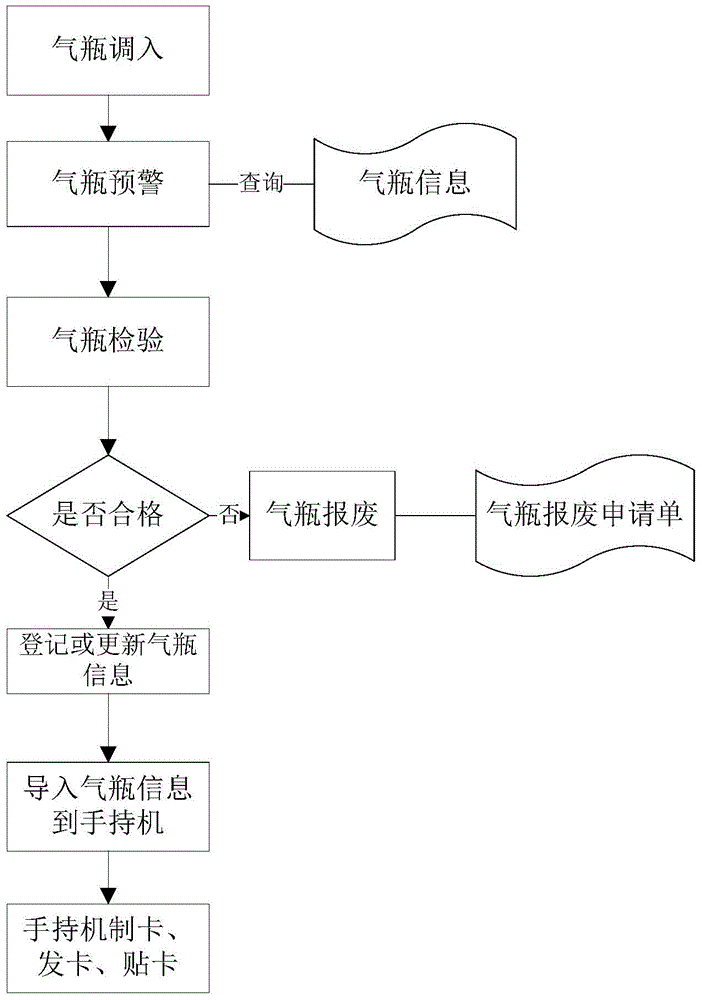

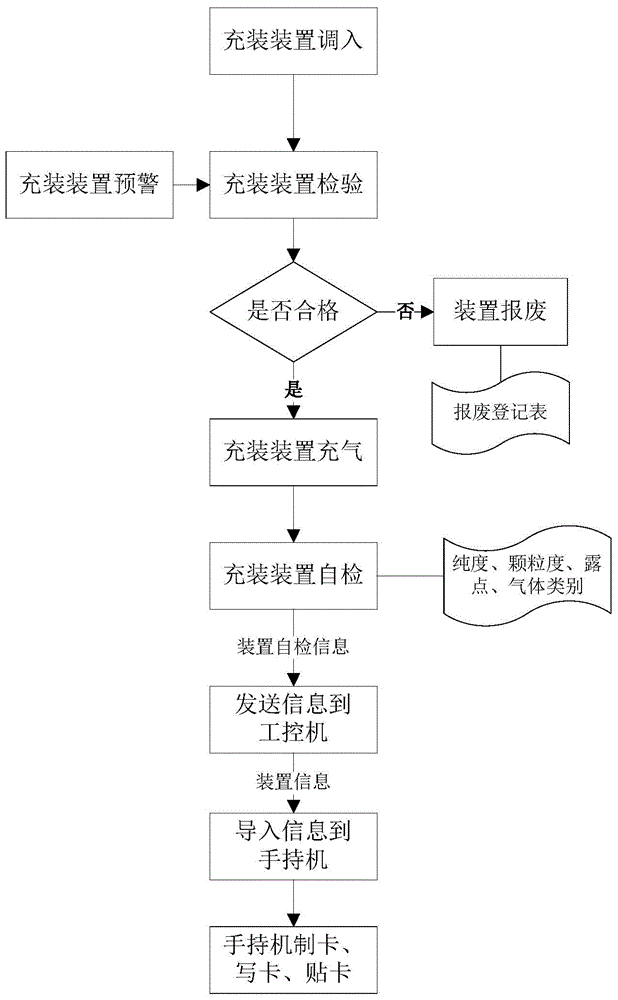

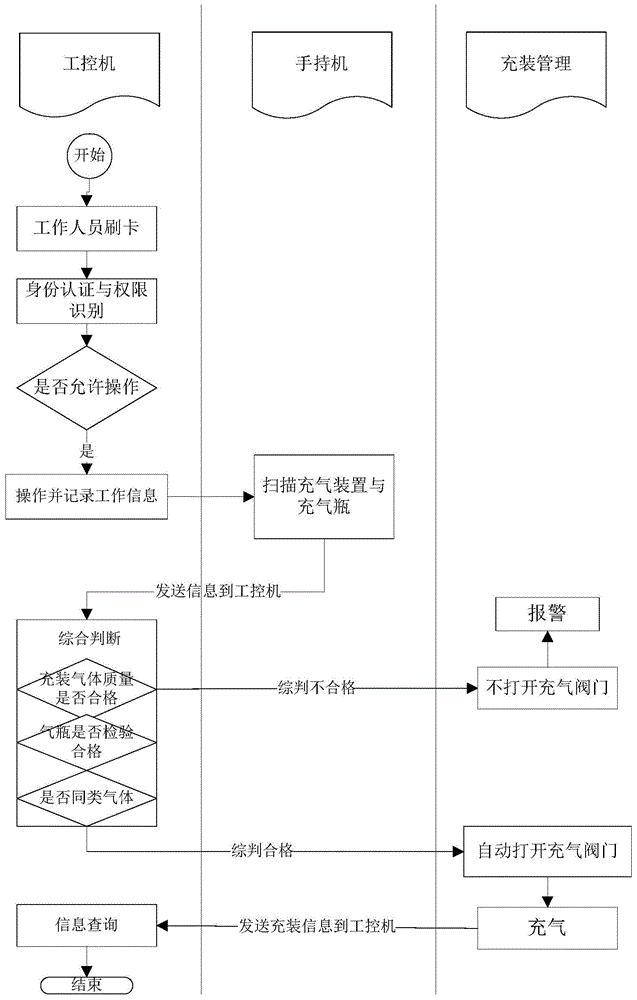

[0029] Embodiment one, such as figure 1 , figure 2 , image 3 Shown: the present invention also provides a kind of gas bottle safety supervisory method, comprises:

[0030] Step 1): Inspection and information entry of gas cylinders: Carry out manual inspection on imported gas cylinders and register and check information, such as gas cylinder number, type of gas cylinder, date of inspection of gas cylinders, etc. The cylinder will be alerted and the gas cylinder information can be queried. Register or update the information of qualified gas cylinders and import them into the handheld device, and then hold the mechanism card, issue the card, and paste the card, that is, write the corresponding gas cylinder information into the RFID electronic tag through the handheld device, and paste the RFID electronic tag to the corresponding On the gas cylinder, and send the gas cylinder information written into the RFID electronic tag back to the industrial computer through the handheld...

Embodiment 2

[0040] Embodiment two, such as figure 1 , figure 2 , Figure 4 Shown: the present invention also provides a kind of gas bottle safety supervisory method, comprises:

[0041] Step 1): Inspection and information entry of gas cylinders: Carry out manual inspection on imported gas cylinders and register and check information, such as gas cylinder number, type of gas cylinder, date of inspection of gas cylinders, etc. The cylinder will be alerted and the gas cylinder information can be queried. Register or update the information of qualified gas cylinders and import them into the handheld device, and then hold the mechanism card, issue the card, and paste the card, that is, write the corresponding gas cylinder information into the RFID electronic tag through the handheld device, and paste the RFID electronic tag to the corresponding On the gas cylinder, and send the gas cylinder information written into the RFID electronic tag back to the industrial computer through the handhel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com