On-line rapid workpiece label positioning method based on image processing

A technology of image processing and positioning methods, applied in image data processing, image analysis, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Below in conjunction with accompanying drawing and embodiment, the present invention will be further described:

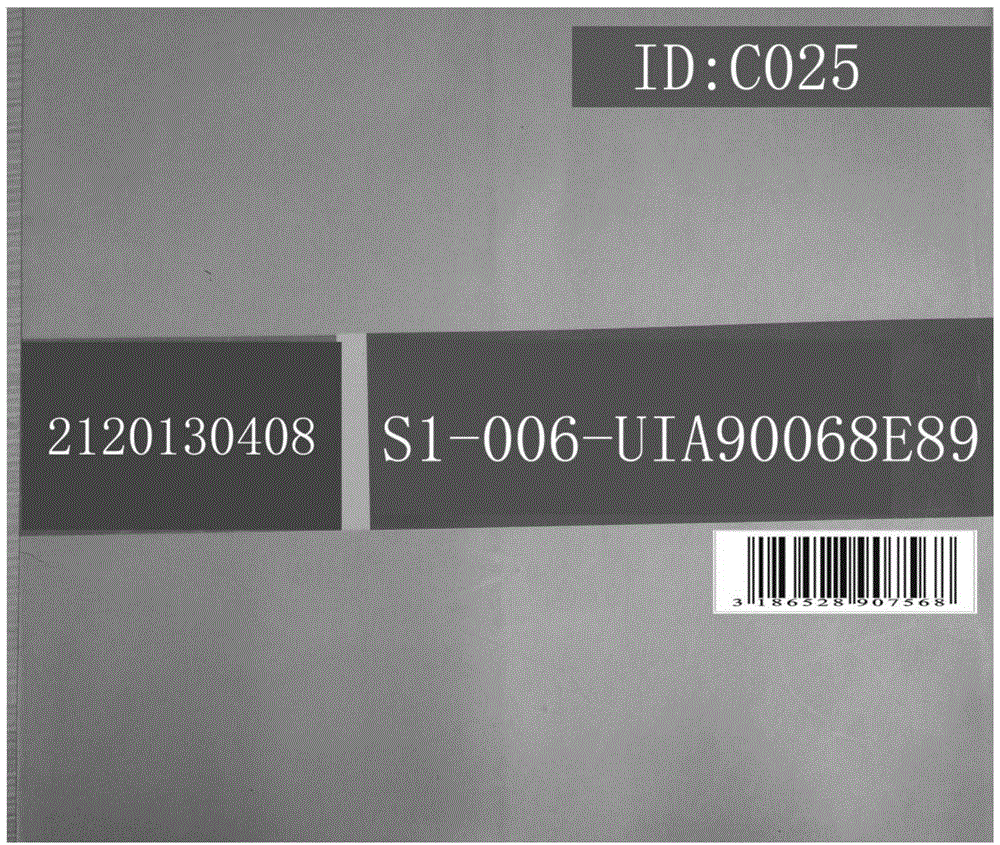

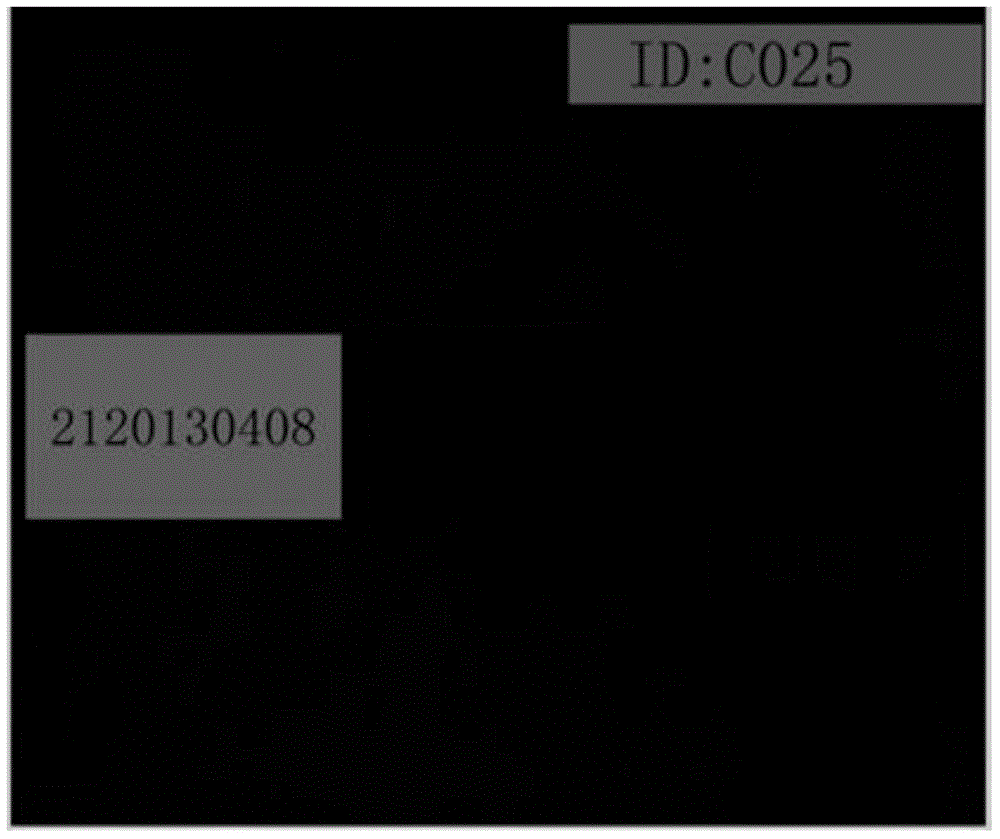

[0062] The original image in this example is as figure 1 As shown, its background color is blue, using a kind of image processing-based online rapid positioning method for workpiece labels proposed by the present invention, from such as figure 1 Locate the workpiece label area in the image shown, and the specific steps are as follows:

[0063] Step 1: Determine the background color of the workpiece label, and perform the operation of step 2 for the original image containing the workpiece label with a blue background color.

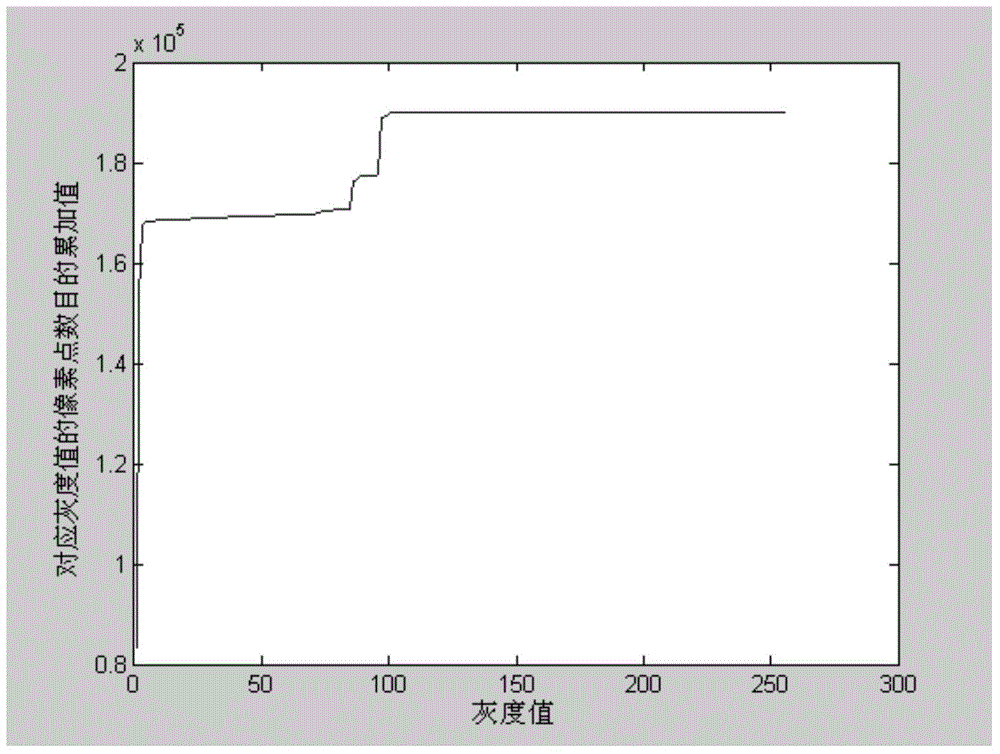

[0064] Step 2: Obtain the red, green, blue (RGB) color space values of the original image, and convert the red, green, blue color space values of the image to the lightness, hue, and saturation (YUV) color space using the formula (1) The U component gray value in the value, k in the formula (1) 1 =0.14713,k 2 =0.28886, the result...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com