Binding device for overhead lead and stay wire

A technology for overhead wires and binding devices, which is applied in the direction of adjusting/maintaining mechanical tension, which can solve the problems of inconvenient operation, reducing the toughness of aluminum wires, and time-consuming, so as to shorten the working time, improve the safety factor, and bind tightly and reliably. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

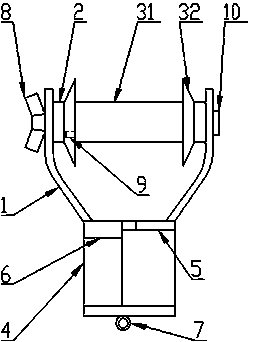

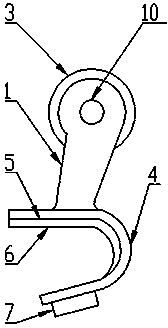

[0032] Binding devices for overhead conductors and guy wires, such as figure 1 and figure 2 As shown, it includes a device body, a reel 3, a binding arc 4, and a jack 7.

[0033] The illustrated reel 3 is arranged on the upper end of the device body, and passes through a central shaft 10 between two opposite support arms 1 . The support arm frame 1 is made of plate metal, and the metal plates of the two support arm frames 1 are parallel to each other. The upper part of the support arm frame 1 corresponding to the installation of the winding wheel 3 is set in a disc shape, and the center of the disc shape is provided with a central hole. And the middle part of the disc shape protrudes slightly outwards, and the outer edge of the disc shape slightly closes inward.

[0034] The winding wheel 3 includes a winding shaft 31 and two retaining wheels 32 . T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| End diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com