Illumination hinge

A hinge and battery pack technology, applied in the field of cabinets, can solve problems such as insufficient battery voltage, increased cost, and inability to pull up, and achieve the effects of reducing maintenance cost, increasing quantity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

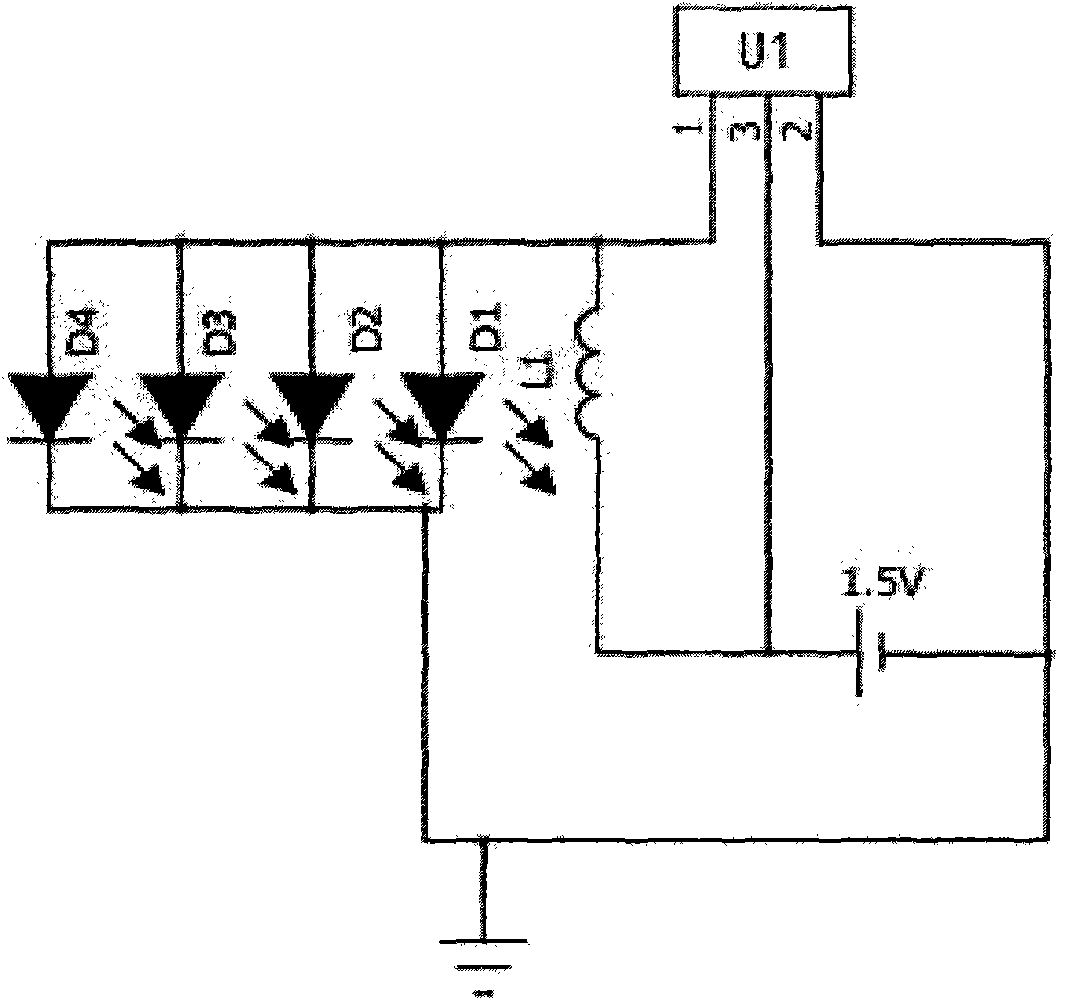

[0016] A lighting hinge, the lighting hinge includes 4 LED lamp beads D1-D4 arranged in parallel, and a battery pack, a step-up drive module U1 is connected between the positive pole of the battery pack and the positive pole of the LED lamp bead, the The negative electrode of the LED lamp bead is coupled to the negative electrode of the battery pack; the battery pack includes at least one battery of 0.8V-1.5V.

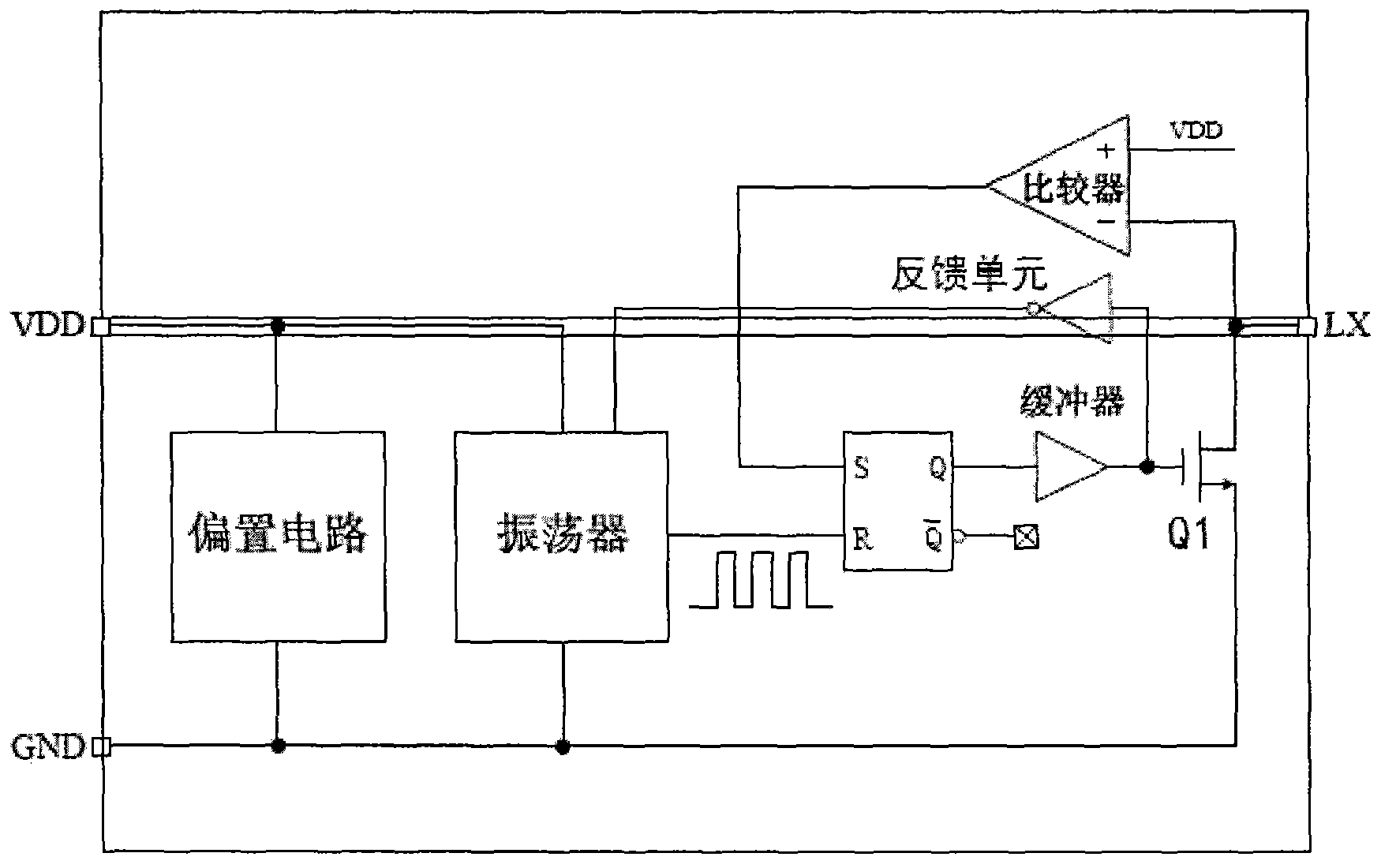

[0017] see figure 1 The step-up driver module U1 includes a power supply pin VDD, a power supply pin LX, and a ground pin VDD. The positive pole of the LED lamp bead is connected to the power supply pin VDD (the first pin), and the negative pole is connected to the ground pin GND (the first pin). 3 pins); the supply pin is coupled to the positive terminal of the battery pack; an inductor is connected between the supply pin and the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com