Stir-fry control method and stir-fry mechanism of automatic cooking equipment

An automatic cooking and stir-frying mechanism technology, applied in cooking utensils, household utensils, applications, etc., can solve the problems of decreased stability, increased complexity of equipment, and mutual interference of various components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

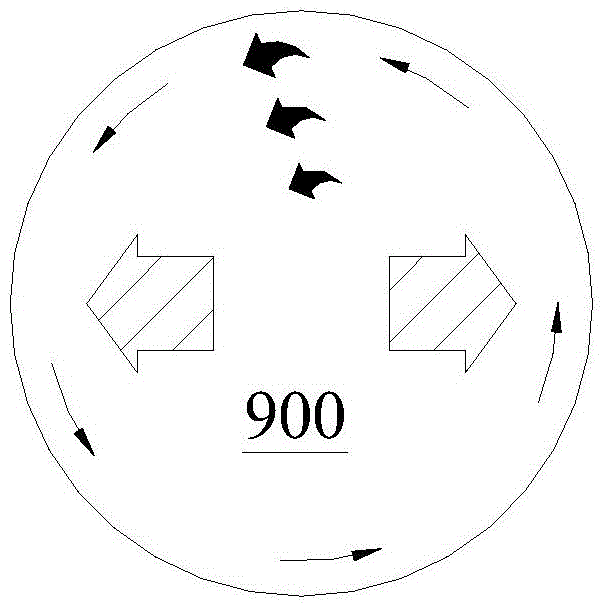

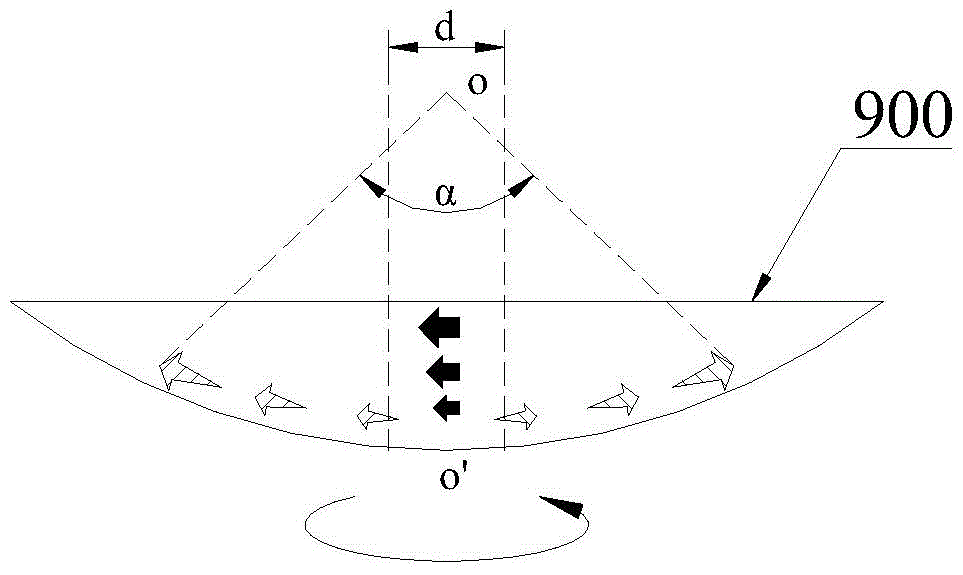

[0061] Method Example 1: Combining figure 1 and figure 2 The stir-frying control method for automatic cooking equipment shown includes three actions: the rotation of the pot body 900 to drive the rotation of the ingredients in the pot, as shown by the single-line arrow in the figure; The action of dispersing is shown by the obliquely shaded arrow in the figure; and the action of scraping the ingredients along the circumference of the pot body to collect them in the middle of the pot body is shown by the solid arrow in the figure.

[0062] The three actions of rotating the ingredients, dispersing the ingredients and gathering the ingredients are carried out simultaneously without interfering with each other. In order to achieve this purpose, in terms of structural design, a scraper that is stationary relative to the pot body and extends into the pot can be used to scrape the food in the circumferential direction, and a stirring head can be used to reciprocate and swing along ...

Embodiment 2

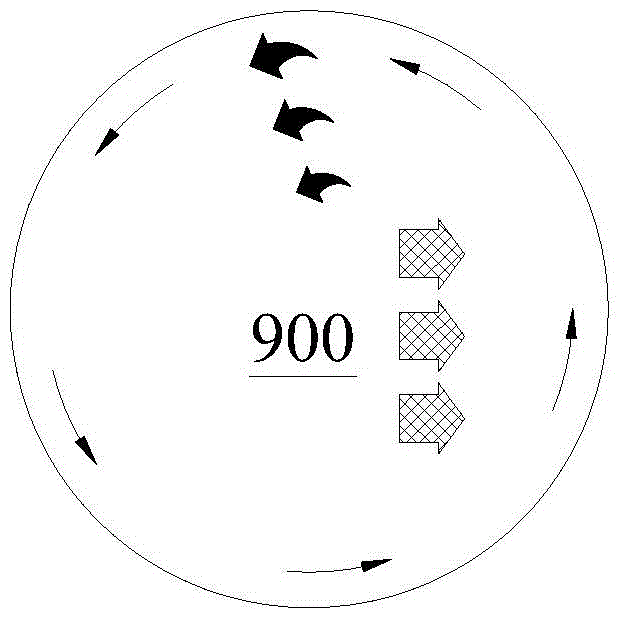

[0068] Method Embodiment 2: This embodiment is further improved on the basis of Embodiment 1, combining image 3 and Figure 4 As shown, in addition to the basic actions of the above-mentioned embodiment 1, this embodiment also includes a food-aiding action of pushing the food toward the moving direction of the pot body 900 during the pot turning process, as shown by the square arrow in the figure. Combined with the above-mentioned structure, the action of pushing the ingredients is specifically to push the ingredients by unidirectional swinging of the stirring head along the moving direction of the pot body 900 . In the automatic cooking equipment with the function of turning over the pot, the ingredients in the pot can be thrown up by the actions of the pot body 900 such as accelerating forward, tilting down, and upturning, as shown by the dotted arrow in the figure, and catching the falling food. Foodstuffs, the specific process can be found in the invention patent No. 201...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com