Split type splashing-proof flask device

An anti-splash, split-type technology, applied in the direction of the flask, etc., can solve the problems of chemical reagents splashing out of the flask, cumbersome operation, and difficult cleaning of the flask

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

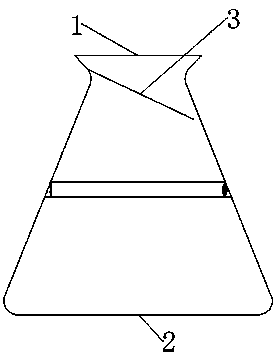

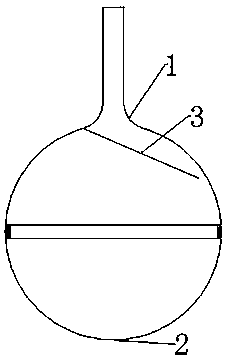

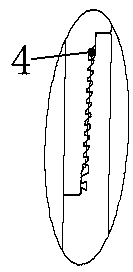

[0015] It can be seen from the accompanying drawings that a split-type anti-splash flask device includes: an upper body 1, a lower body 2, an anti-splash drainage plate 3, and a rubber sealing ring 4. The upper body 1 and the lower body 2 are connected by threads to prevent splash drainage The plate 3 is fixed on the bottle mouth of the upper body 1 , and a sealing device 4 is provided at the junction of the upper body 1 and the lower body 2 . During use, directly pour the reaction reagent into the flask, and the anti-splash drainage plate 2 will guide the reagent to the inner wall of the flask, and the reagent will slowly flow to the bottom of the bottle along with the inner wall, without the need for a drainage rod, which completely solves the problem of liquid splashing out of the flask The problem is that after the reaction is over, the upper body 1 and the lower body 2 can be disassembled by rotating the lower body 2, which makes the cleaning of the flask more convenient. ...

Embodiment 2

[0017] As an improvement of the present invention, the sealing device 4 is made of a heat-resistant rubber sealing ring. The chemical reaction is often accompanied by high temperature and gas collection. After adopting this design, the problem of gas flowing out from the connection between the upper body and the lower body can be solved . The rest of the structural features and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0019] As an improvement of the present invention, the upper body 1 and the lower body 2 are combined into a triangular flask. With this design, the detachable flask can be used as a triangular flask, which is convenient for the operator to shake and speed up the reaction. All the other structures and advantages are identical to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com