Plate-type cotton swab cleaning machine

A washing machine and cotton swab technology, applied in cleaning methods and utensils, liquid cleaning methods, chemical instruments and methods, etc., can solve problems such as inability to achieve cotton swab soaking cleaning, low cleaning efficiency, uneven cleaning, etc., and achieve dismantling Easy installation, high cleaning efficiency, uniform spraying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

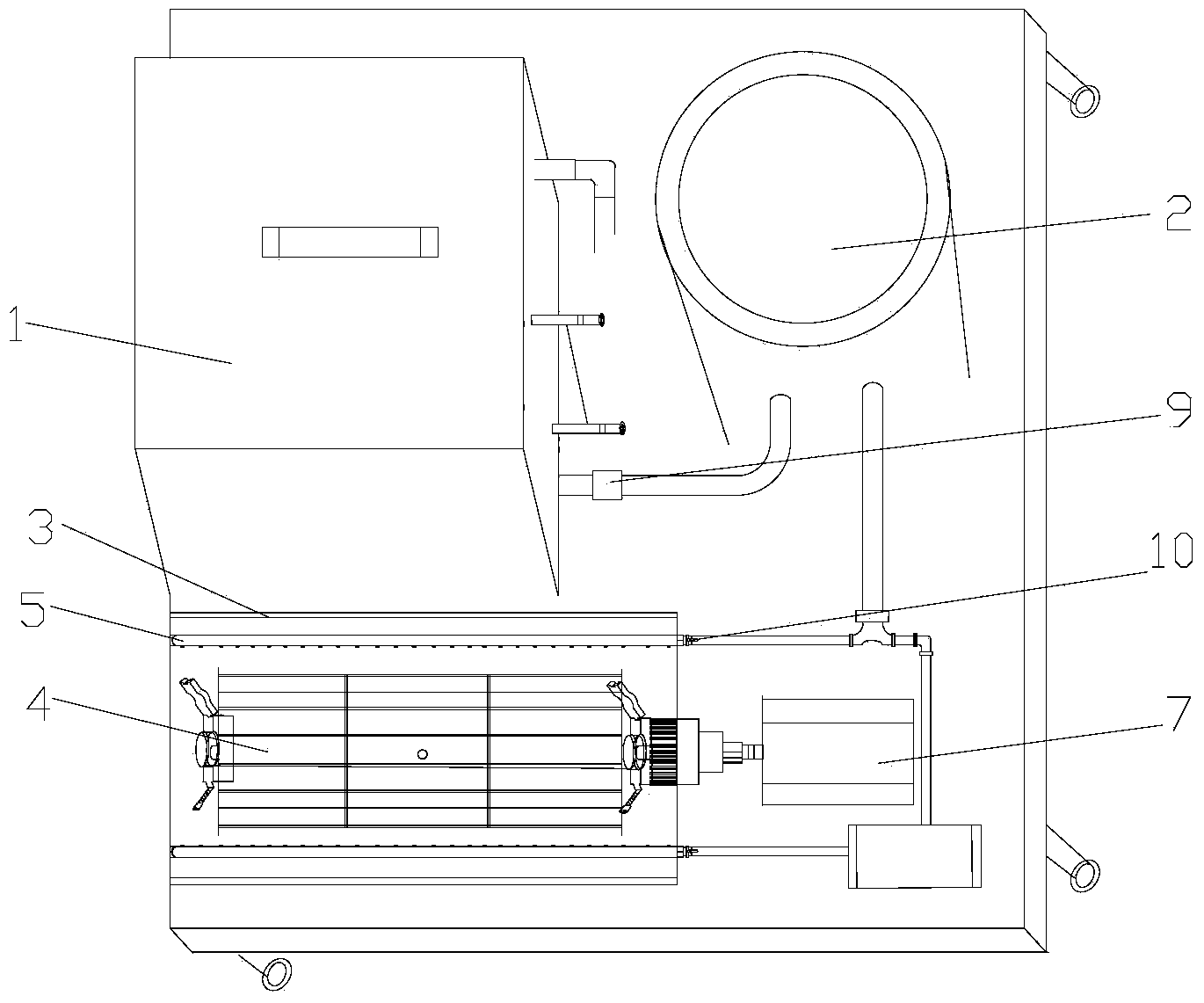

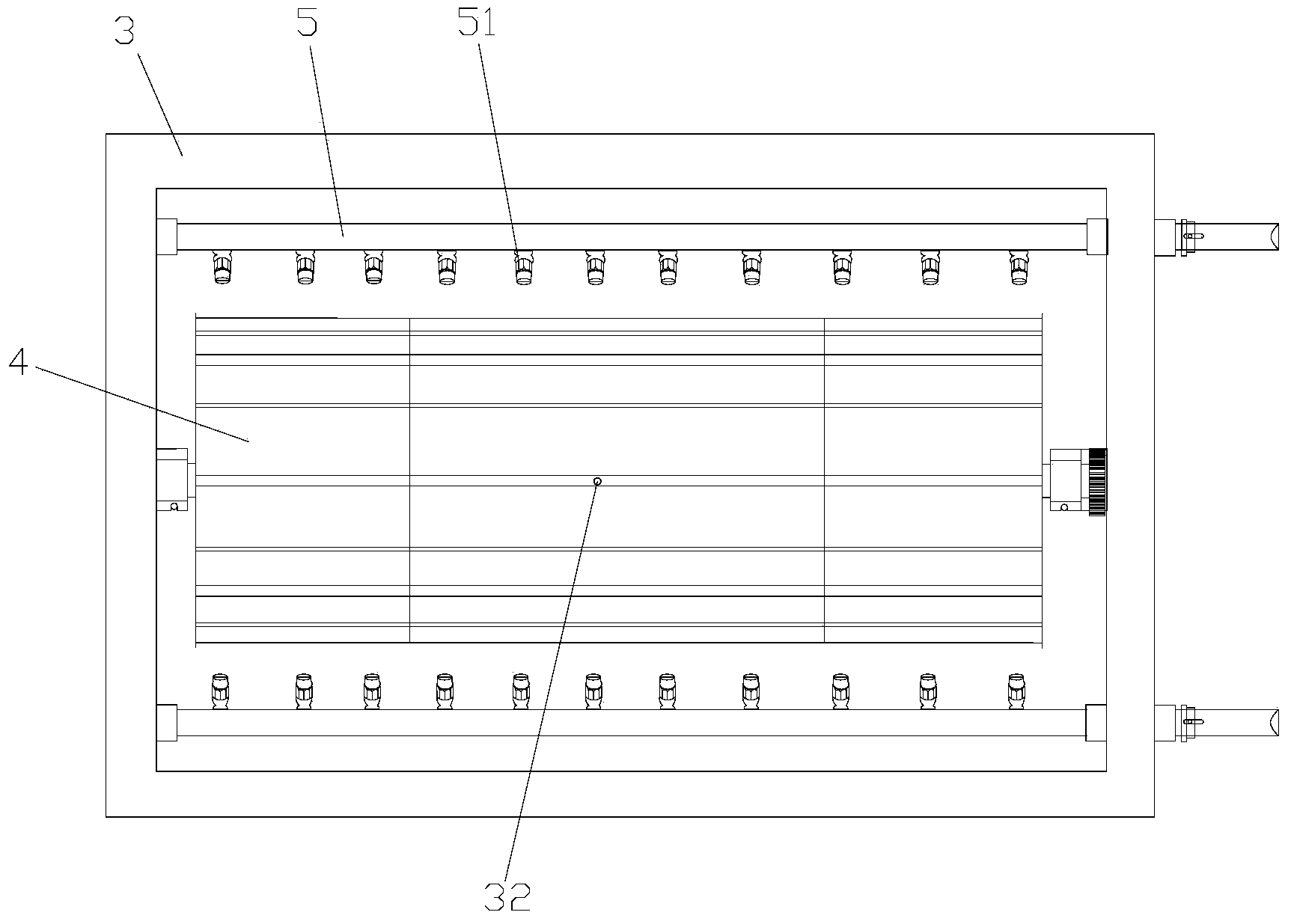

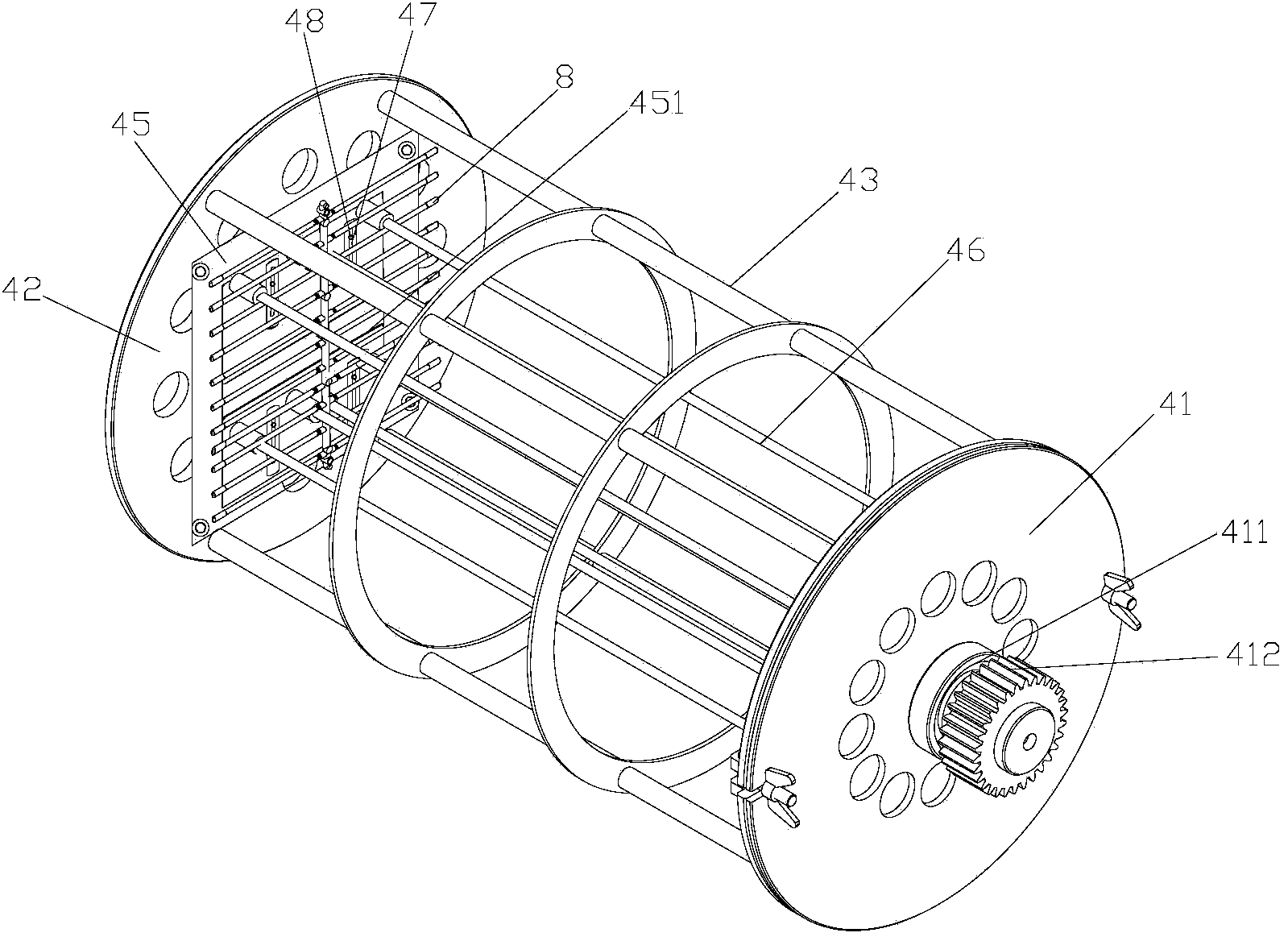

[0020] Such as figure 1 and figure 2 As shown, the plate-type cotton swab cleaning machine of the present invention includes a water supply tank 1, a high-pressure pump 2, and a spray box 3. A rotatable cleaning basket 4 for installing plate-type cotton swabs is installed in the spray box 3. The cleaning basket 4. A spray pipe 5 is arranged on the periphery. The spray pipe 5 is installed on the spray box 3. At least one nozzle 51 is arranged on the spray pipe 5. The water outlet direction of the nozzle 51 faces the cleaning basket 4. The water supply tank 1, high pressure The pump 2 communicates with the spray pipe 5 in sequence. Plate-type cotton swabs 8 are installed in the cleaning basket 4. When the cleaning basket 4 rotates, the water sprayed from the nozzle 51 rinses the plate-type cotton swabs 8, so that the inside of the cotton swabs can be soaked and cleaned, and the spraying can be even. Cleaning, high cleaning efficiency, low humidity of the cotton swab after cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com