Scooter handlebar vertical tube punching die

A scooter and handlebar technology, which is applied in the field of scooter handlebar riser punching dies, can solve the problems of high processing cost, not punching in place, and skewed hole position, and achieve the effect of reducing processing cost and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be described in further detail below in conjunction with the accompanying drawings.

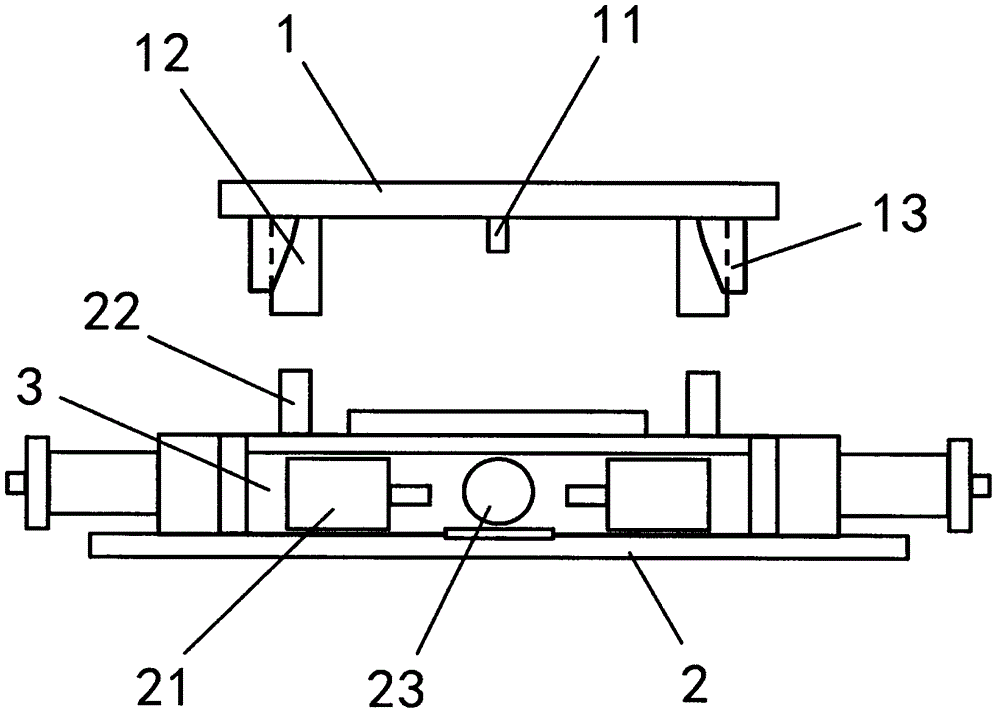

[0008] Such as figure 1 Shown, a kind of scooter handlebar riser punching die is characterized in that: comprise upper mold 1 and lower mold 2, described upper mold 1 is provided with upper punch needle 11, guide pipe 12 and inclined-plane push block 13, so The lower die 2 is provided with slider punching pins 21 on both sides, guide posts 22 and standpipe positioning posts 23 .

[0009] During work, put the handlebar standpipe on the standpipe positioning column 23, the upper die 1 punches downwards, the upper punching needle 11 and the inclined-plane push block 13 rush down together, the upper punching needle 11 rushes to the handlebar standpipe, and the inclined-plane pushes The block 13 rushes into the gap 3 formed between the slider punching pin 21 and the lower die, and the inclined-plane push block 13 pushes the slider punching pin 21 through the incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com