Vehicle clamp capable of fast replacing machined part

A technology of processed and turning fixtures, applied in the field of turning fixtures, which can solve the problems of increased time for switching processed products, affecting production efficiency, poor versatility, etc., and achieves the effects of improving machining accuracy and efficiency, convenient selection, and reducing quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in further detail below in conjunction with accompanying drawing:

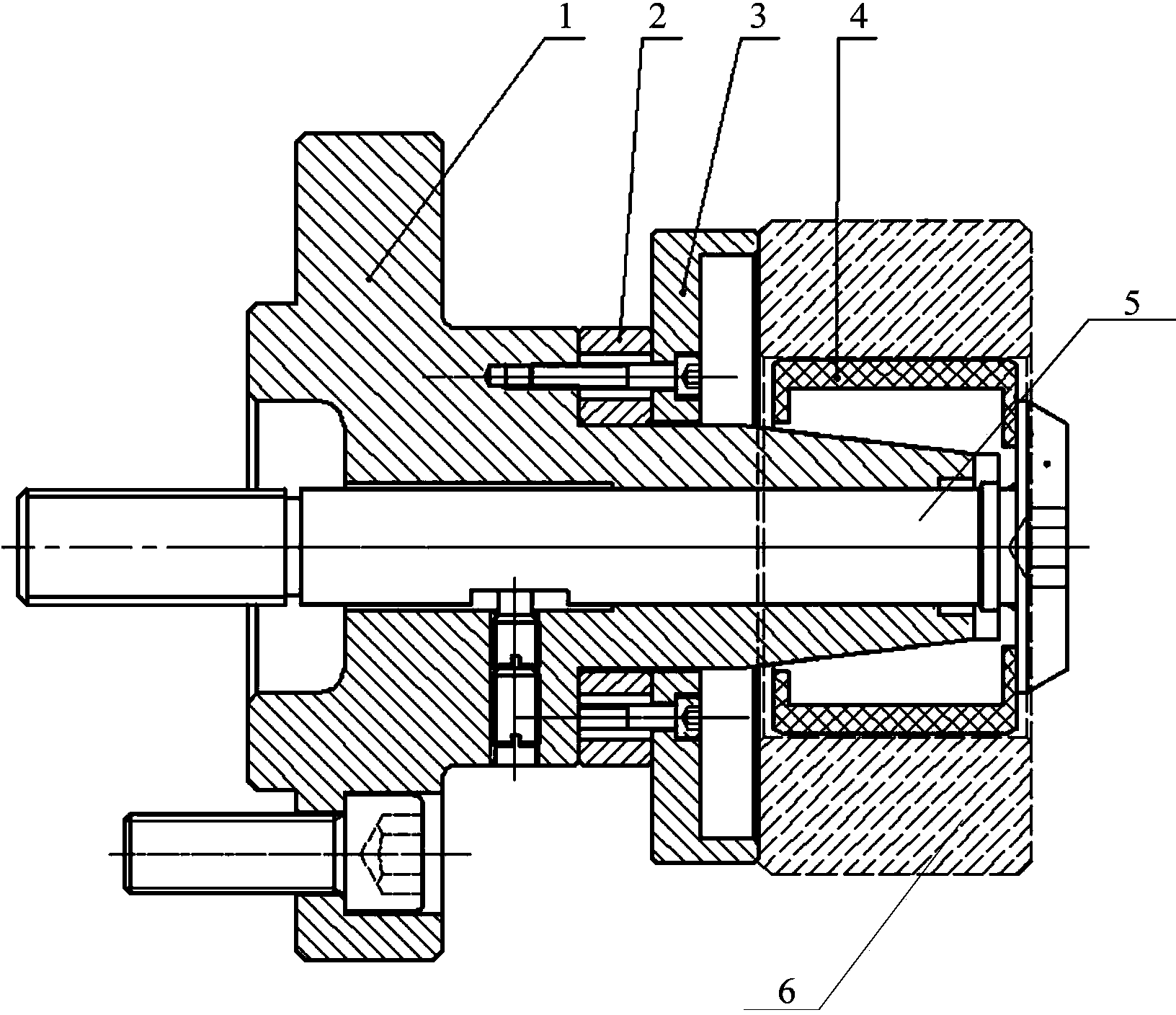

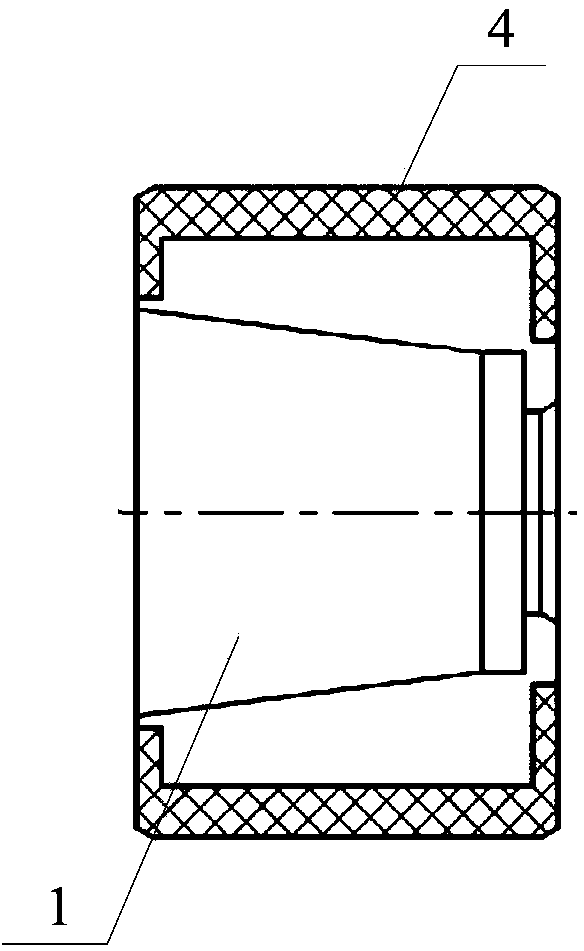

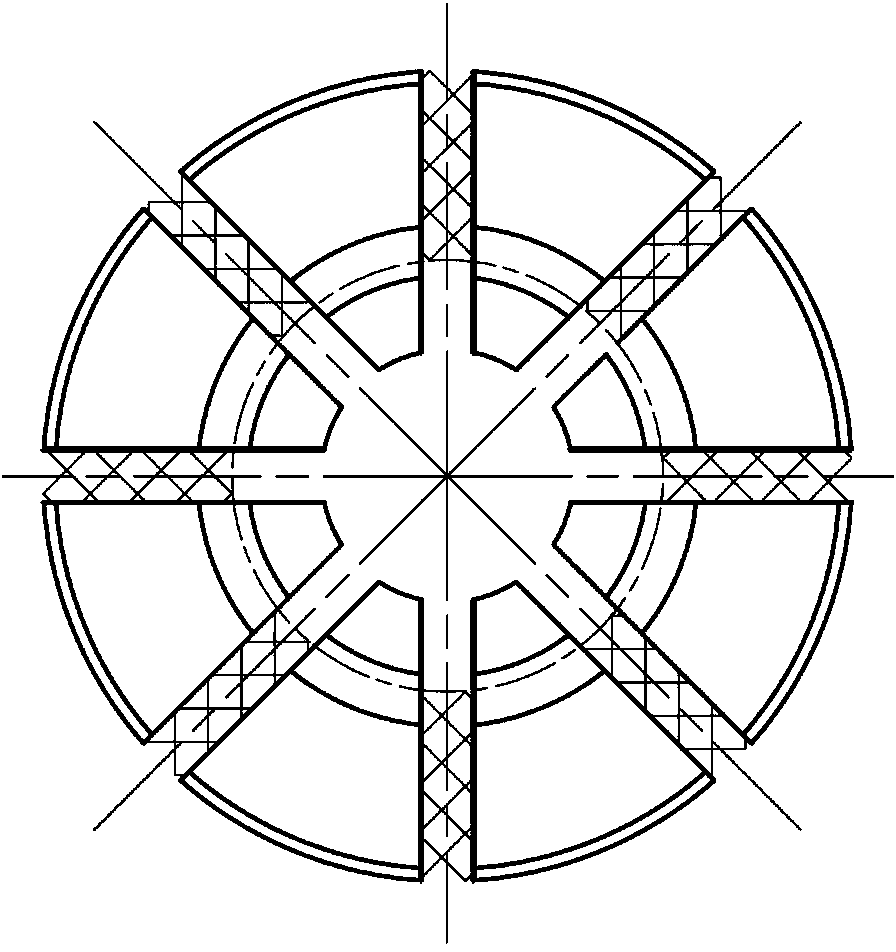

[0016] see Figure 1 to Figure 3 The present invention includes a body 1 installed on the machine tool workbench. The front end of the body 1 is equipped with a tie rod 5 connected to the machine oil cylinder. Loosen the expansion cover 4 of the processed part 6; when processing, the processed part 6 is set on the expansion cover 4. The expansion sleeve 4 and the pull rod 5 are an integrated structure used for the pull rod 5 to drive the expansion sleeve 4 to move axially together and to loosen the expansion sleeve 4 after processing. The front end of the body 1 is tapered with reduced diameter; as figure 2 As shown, the expansion sleeve 4 is a hollow cylindrical structure formed by bonding, and one end surface of the expansion sleeve 4 is provided with a tapered hole that matches the tapered portion of the front end of the body 1; image 3 As shown, the diameter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com