Full-automatic guide rail cutter and cutting process

A cutting process and cutter technology, applied in shearing devices, manufacturing tools, metal processing equipment, etc., can solve the problems of low yield, cumbersome operation, affecting the efficiency of rail cutting, etc., to improve cutting efficiency and ensure accuracy. , to ensure the cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0035] The fully automatic guide rail cutter provided in this example, when cutting the track, makes the guide rail to be cut drop to the position to be cut with gravity, and is triggered by the guide rail to be cut down to the cutting position to start the cutting tool to descend to the position to be cut The guide rail cuts and counts the cutting action at the same time, so as to control the cutting action to stop.

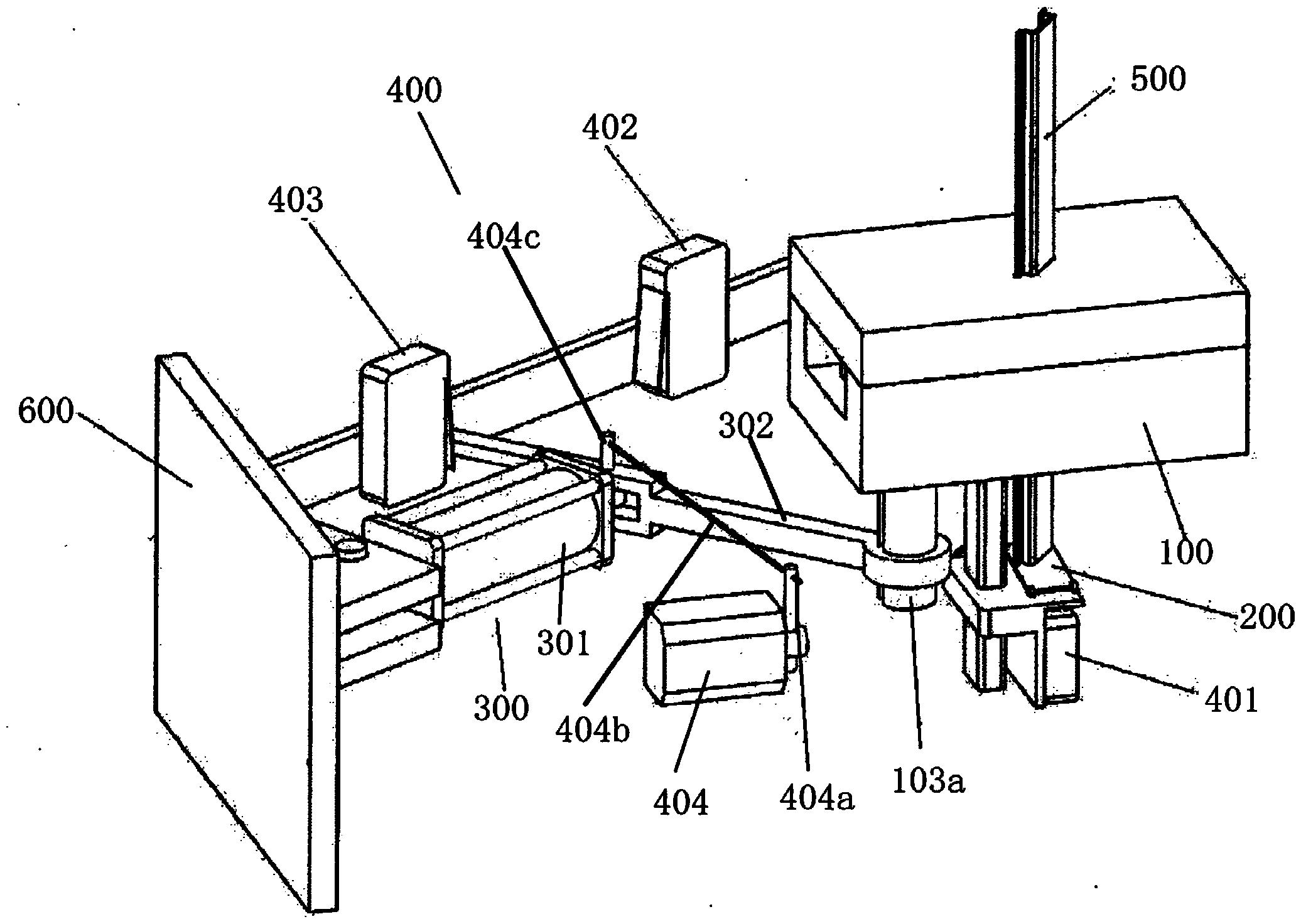

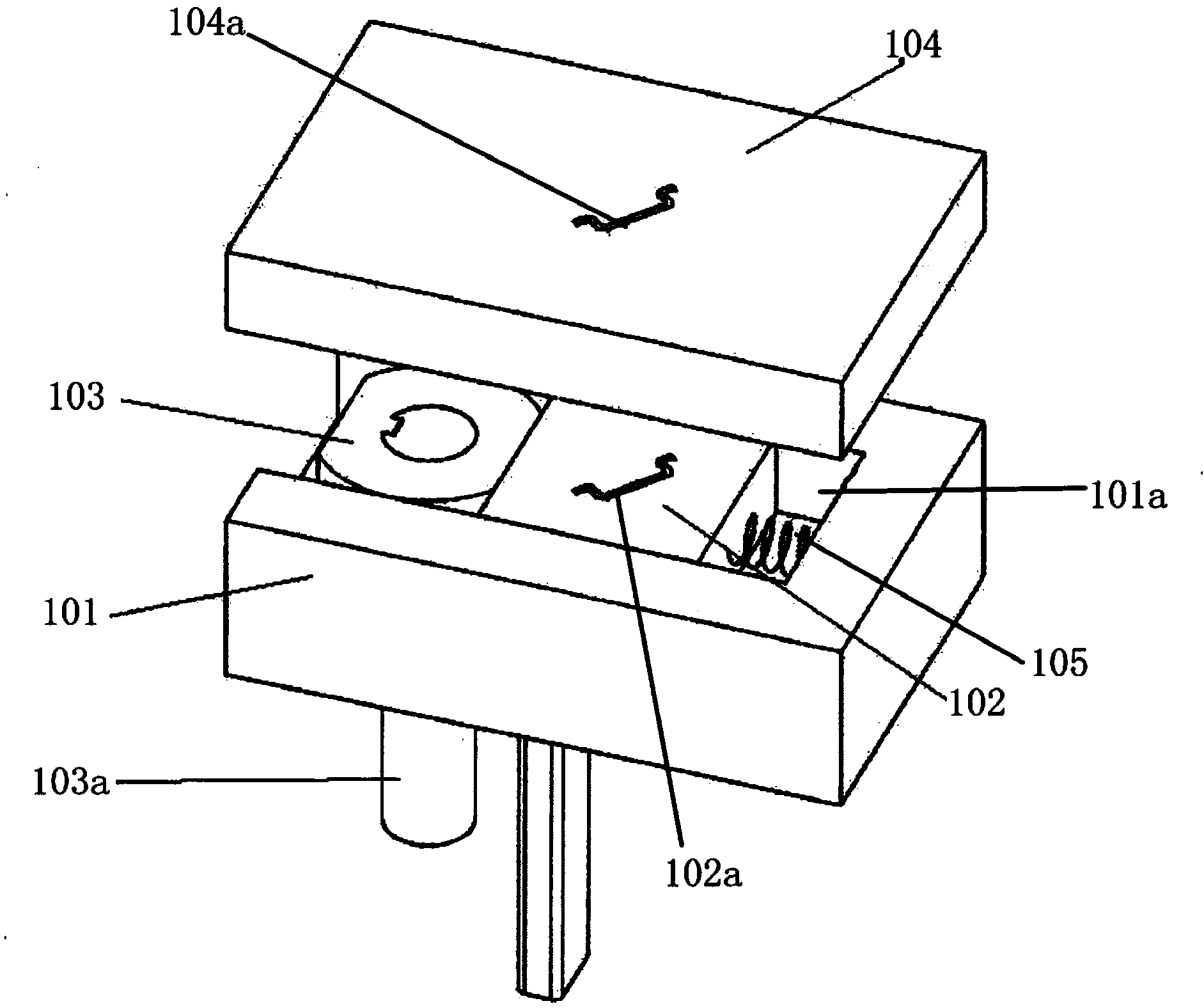

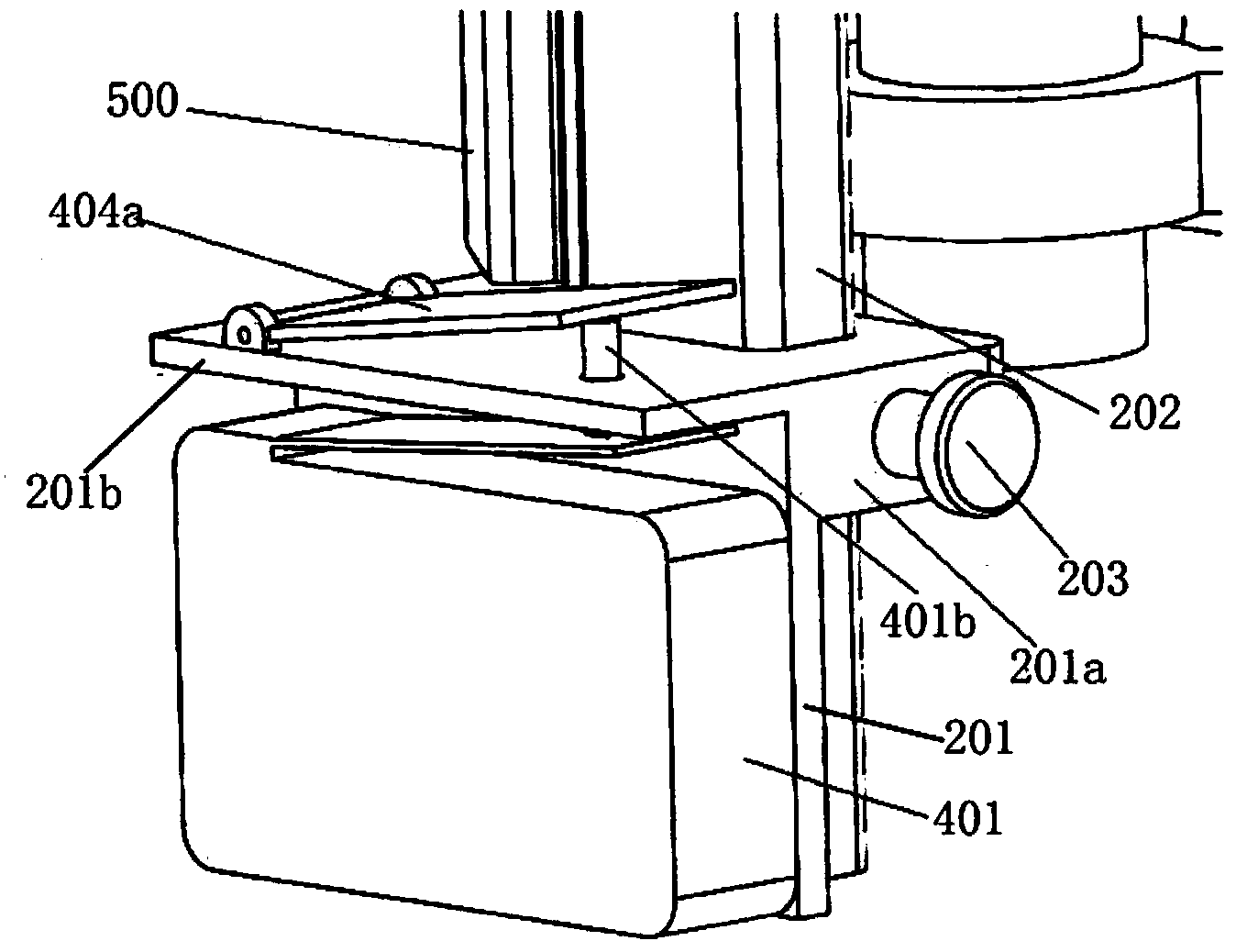

[0036] see figure 1 , which is a schematic structural view of a fully automatic guide rail cutter formed based on the above principles. It can be seen from the figure that the fully automatic guide rail cutter is mainly formed by the cooperation of a cutting tool 100 , a positioning mechanism 200 , a driving mechanism 300 and a t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap