Omni-directional mobile tooling for assembly of rotary shell products

An omnidirectional movement and product technology, applied in the direction of assembly machines, manufacturing tools, workpiece clamping devices, etc., can solve the problems of assembly workshops such as high requirements, lack of flexibility, and low efficiency, so as to reduce the workshop area, reduce costs, The effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

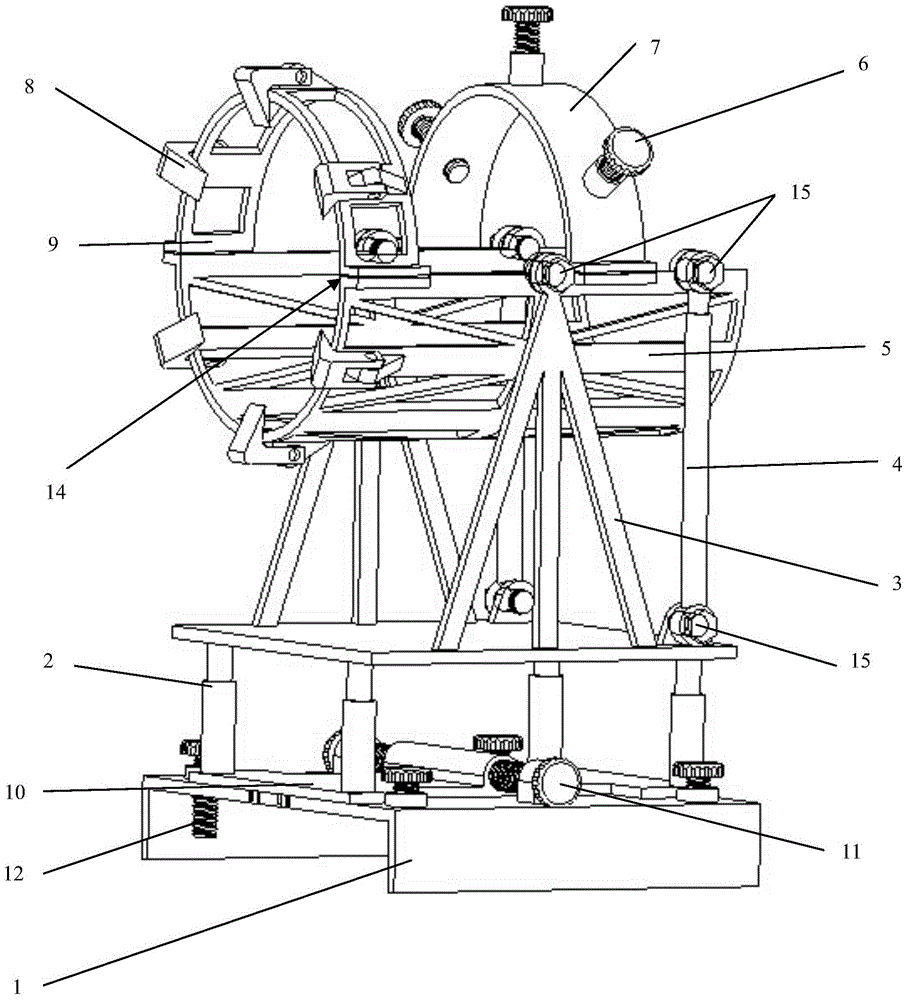

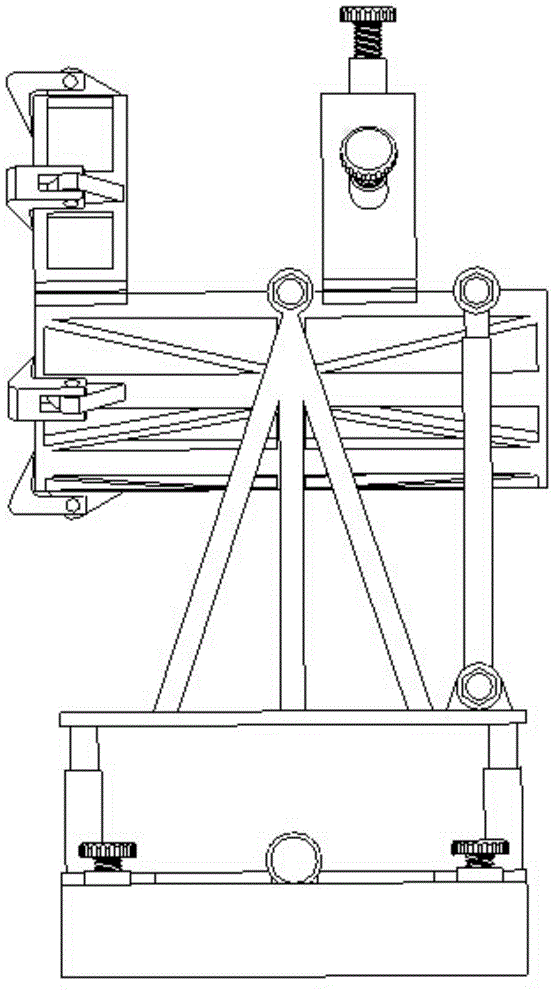

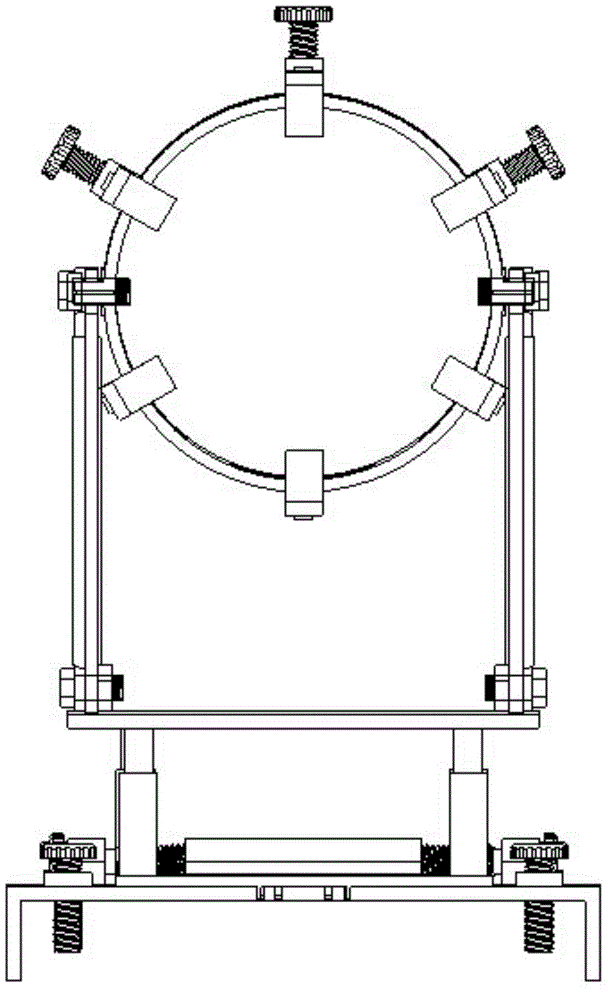

[0033] The following structural drawings and embodiments further illustrate the present invention.

[0034] Such as Figure 1-7 shown.

[0035] An omnidirectional mobile tooling for the assembly of rotary shell products, such as Figure 1-4 As shown, it mainly includes:

[0036] A chassis 1 for installation on the omnidirectional mobile platform based on Mecanum wheels, the chassis 1 is fixedly connected with the omnidirectional mobile platform through bolts 12, so that the omnidirectional mobile tool installed on the chassis 1 can move in all directions Under the control of the platform, it can move freely along the x-axis and y-axis in the horizontal direction;

[0037] A support plate 10 installed on the chassis 1; the support plate 10 can move along the Y direction with the chassis 1 ( figure 1 left and right directions),

[0038] A lead screw 11 connecting the chassis 1 and the support plate 10 to ensure that the chassis 1 and the support plate 10 are along the x-axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com