An electronic grain counting machine with a forced dust suction device

A technology of dust collection device and grain counting machine, which is applied in packaging, dust removal, transportation and packaging, etc. It can solve the problems of increased manufacturing cost, inaccurate counting of grains, and reduced production efficiency, so as to improve the quality of air tightness and ensure Stability and the effect of ensuring production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

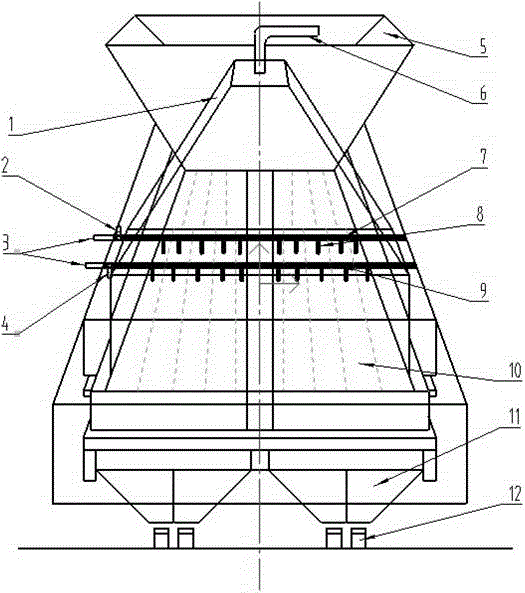

[0022] An electronic grain counting machine with a forced dust suction device figure 1 , wherein the dust collection hood 1 and the hopper 5 are located above the oscillating plate 10, the dust collection hood 1 is located in front of the hopper 5, the top of the dust collection hood 1 is connected to the suction pipe 6, the bottom is connected to the compressed air pipeline 3, and the compressed air pipeline is 3 points There are two pipelines at the front and back, the one on the rear side is the primary compressed air purging device 7, and the one on the front side is the two-stage compressed air purging device 9, and the two pipelines are respectively equipped with an air intake control valve 2 and an air intake control valve. Valve 4, air blowing pipe 8 is equipped with below two pipelines, and electronic counting device 11 is positioned at the front of oscillating plate 10, and its below is medicine bottle bracket.

[0023] The operation mode of the above electronic coun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com