Soft-bag converging and separating device

A soft bag and guiding device technology, applied in conveyor control device, packaging, transportation and packaging, etc., can solve the problems of difficult high-speed production, increase production cost, need air source, etc., achieve smooth movement, save manufacturing cost, The effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

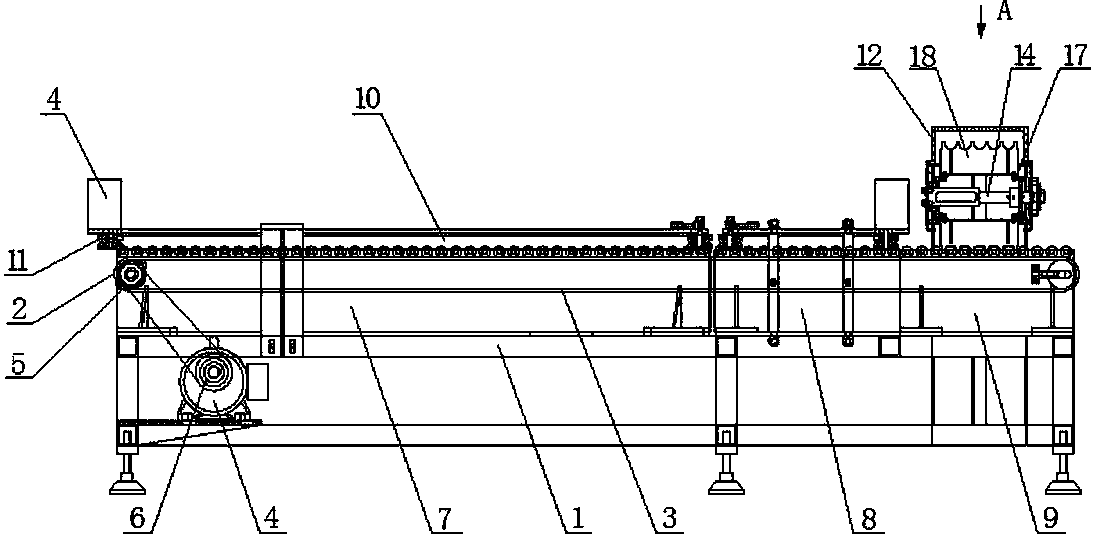

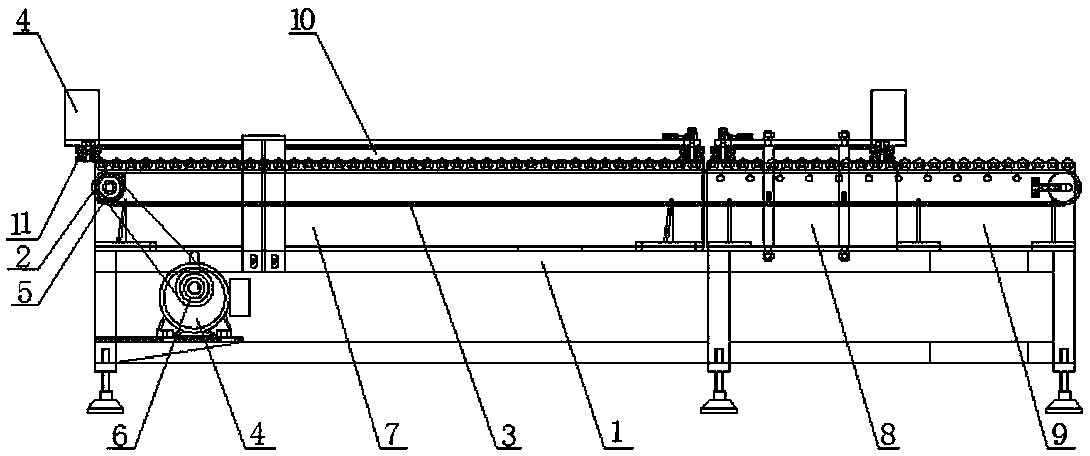

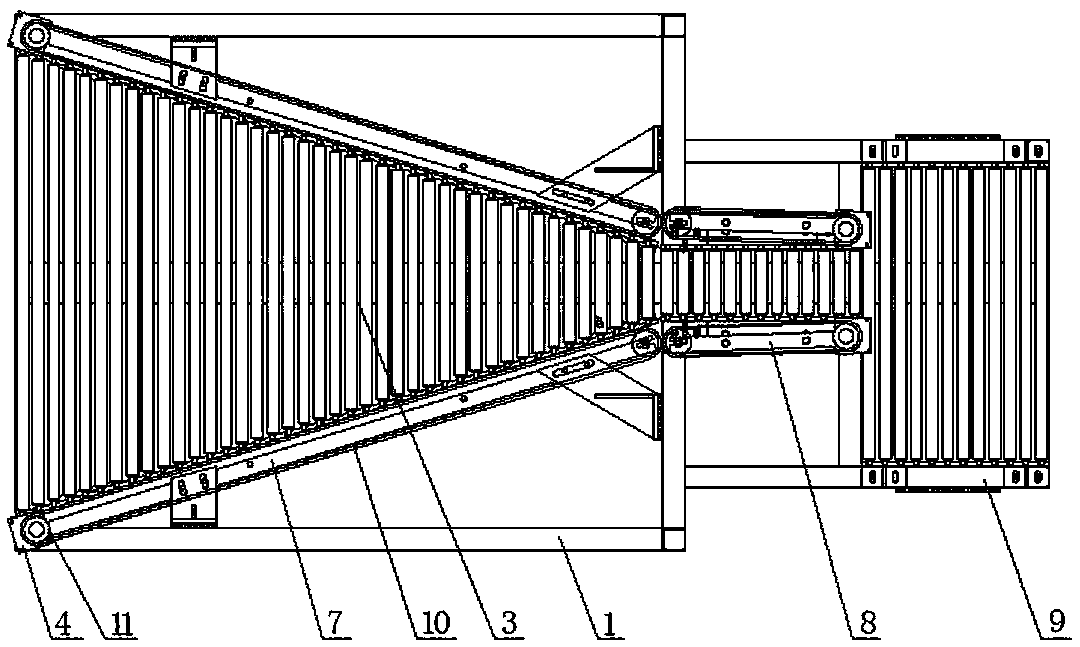

[0021] Such as Figure 1-5 As shown, a soft bag confluence and lane separation device includes a frame 1, a transmission device, a guide device and a lane separation device. The two ends of the frame 1 are rotatably mounted with rollers 2, and the two rollers 2 are placed between There is a belt I3, the transmission device is composed of a motor 4, a driven sprocket 5 and a driving sprocket 6, the motor 4 is connected with the driving sprocket 6, the driven sprocket is installed on any roller 2, the driving sprocket 6 is connected with the driven sprocket The moving sprocket 5 is connected, and the first roller table 7, the second roller table 8 and the third roller table 9 are arranged on the frame 1 and along the direction of the belt I3. The first roller table 7 is in the shape of a trapezoid as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com