Conveying plate structure for conveying printed paperboards

A technology of printing cardboard and conveying board, which is applied in the field of carton production and medical carton production, can solve the problems of increasing input cost and increasing energy consumption, and achieve the effect of reducing cost input and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

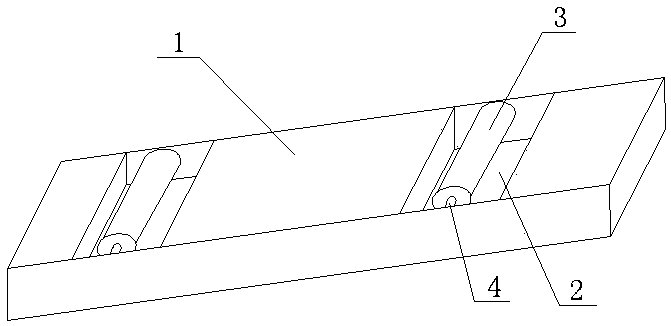

[0015] Such as figure 1 As shown, this embodiment includes a transmission plate body 1, and at least one groove 2 is arranged on the transmission plate body 1. As a preference, two grooves 2 are arranged on the transmission plate body 1 of this embodiment, and the groove 2 is provided with The roller 3 is fixed on the side wall of the groove 2 through the supporting rotating shaft 4 .

[0016] In order to facilitate processing and adapt to the shape of the roller 3, the shape of the groove 2 is designed as a square in this embodiment.

[0017] Preferably, the depth of the groove 2 in this embodiment is equal to or greater than 1 / 2 of the thickness of the transmission plate body 1 .

[0018] Preferably, the diameter of the roller 3 in this embodiment is greater than 1 / 2 of the depth of the groove 2 , and the diameter of the roller 3 is smaller than the depth of the groove 2 .

[0019] As a preference, two grooves 2 are provided on the transmission plate body 1 of this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com