A binder resin composition for toner and its preparation method

A bonding resin and composition technology, applied in the direction of epoxy resin glue, adhesive type, adhesive, etc., to achieve the effects of increased fixing firmness, anti-fouling and improved gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

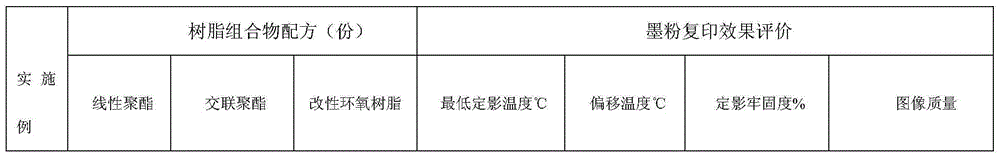

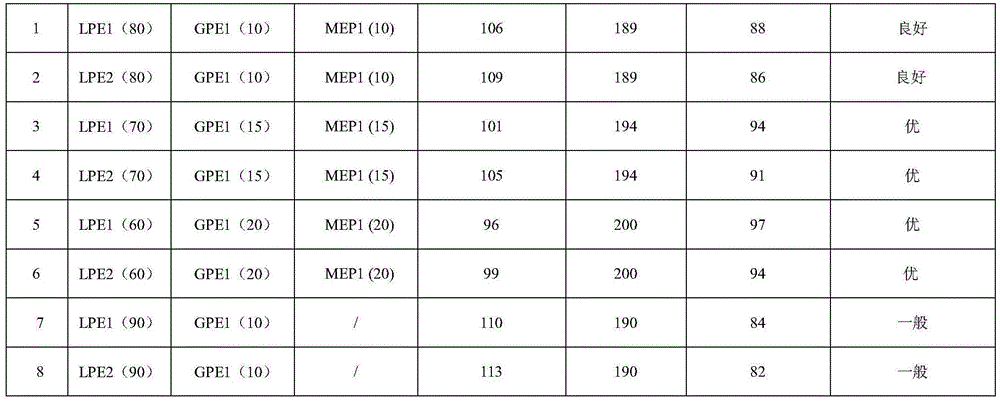

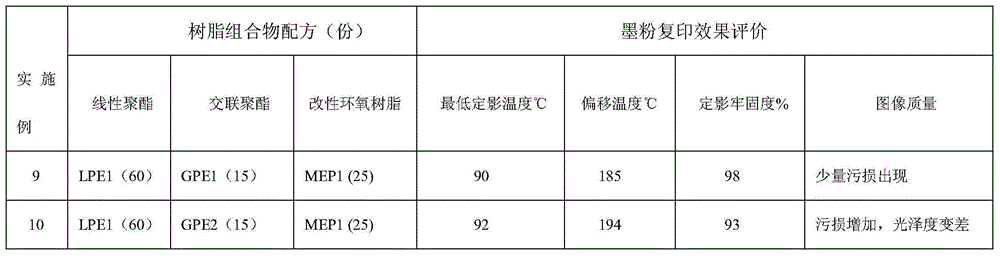

Examples

preparation example Construction

[0020] Preparation of linear polyester 1

[0021] Mix 150 parts of terephthalic acid and 200 parts of propoxylated bisphenol A, add 1 part of tetrabutyl titanate catalyst, react the mixture at 220°C for 4 hours to remove the water generated by the reaction, and then reduce the reaction system Press and vacuum for 1 hour, the vacuum degree is kept at 100-200Pa, and the light yellow transparent material is obtained from the reaction, which is called LPE1. Tg=54°C, Mn=3500, Mw=28000, T 1 / 2 = 115°C. LEP is a linear polyethylene resin.

[0022] Preparation of linear polyester 2

[0023] Mix 100 parts of fumaric acid and 180 parts of ethoxylated bisphenol A, add 1.5 parts of tetrabutyl titanate catalyst, react the mixture at 200°C for 5 hours to remove the water generated by the reaction, and then depressurize the reaction system Vacuumize for 1 hour, keep the vacuum at 100-200Pa, and react to obtain a light yellow transparent material, which is called LPE2. Tg=62℃, Mn=4900, Mw...

Embodiment 1

[0050] 80 parts of LPE1, 10 parts of GPE1 and 10 parts of MEP1 were fully melted and mixed at 150°C for 60 minutes, cooled, solidified, crushed, and finely powdered to obtain adhesive resin composition 1.

Embodiment 2

[0052] 80 parts of LPE2, 10 parts of GPE1 and 10 parts of MEP1 were fully melted and mixed at 175°C for 50 minutes, cooled, solidified, crushed, and finely powdered to obtain adhesive resin composition 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com