A low-activation martensitic heat-resistant steel with oxidation resistance and liquid lead bismuth corrosion resistance

A martensitic steel and liquid lead technology is applied in the field of low-activation martensitic steel with anti-oxidation and anti-corrosion of liquid lead and bismuth, which can solve the problem of not considering the corrosion resistance of liquid lead and bismuth, so as to improve the corrosion resistance of liquid metal, The effect of improving high temperature characteristics and improving strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

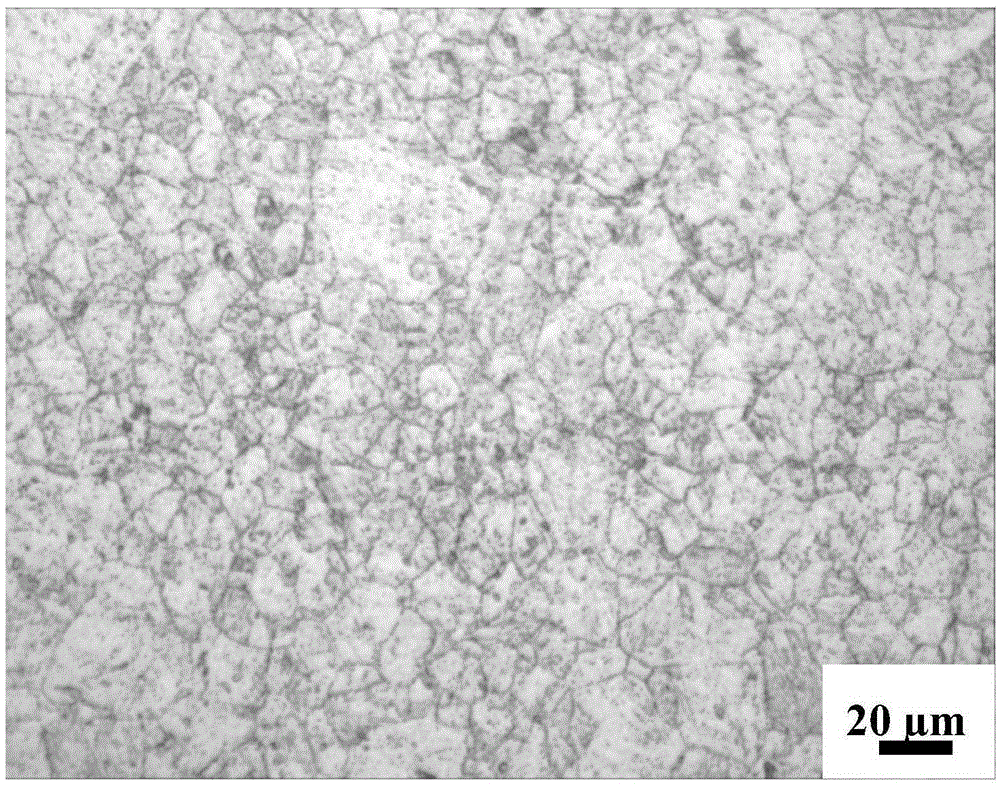

[0018] The chemical composition of martensitic steel is: C: 0.090wt.%, Cr: 8.95wt.%, W: 1.50wt.%, V: 0.20wt.%, Ta: 0.14wt.%, Mn: 0.50wt.%. , Si: 0.59wt.%, Al<0.005wt.%, N: 50 (ppm), Ni: 40 (ppm), Mo: 40 (ppm), Nb: 43 (ppm), Co: 40 (ppm), Ti: 33 (ppm), Cu<0.01wt.%, O: 42 (ppm), P: 48 (ppm), S: 26 (ppm), and the balance is iron.

[0019] The final heat treatment system of the martensitic steel is: normalizing 950-1100°C / 30min / air cooling+tempering 760-800°C / 100min / air cooling.

Embodiment 2

[0021] The chemical composition of martensitic steel is: C: 0.095wt.%, Cr: 8.96wt.%, W: 1.51wt.%, V: 0.21wt.%, Ta: 0.14wt.%, Mn: 0.49wt.%. , Si: 0.60wt.%, Al<0.005wt.%, N: 50 (ppm), Ni: 40 (ppm), Mo: 40 (ppm), Nb: 43 (ppm), Co: 48 (ppm), Ti: 33 (ppm), Cu<0.010wt.%, O: 42 (ppm), P: 48 (ppm), S: 26 (ppm), and the balance is iron.

[0022] The final heat treatment system of the martensitic steel is: normalizing 950-1100°C / 30min / air cooling+tempering 760-800°C / 100min / air cooling.

Embodiment 3

[0024] The chemical composition of martensitic steel is: C: 0.093wt.%, Cr: 9.04wt.%, W: 1.48wt.%, V: 0.18wt.%, Ta: 0.12wt.%, Mn: 0.48wt.%. , Si: 0.53wt.%, Al<0.010wt.%, N: 36 (ppm), Ni: 42 (ppm), Mo: 44 (ppm), Nb: 40 (ppm), Co: 40 (ppm), Ti: 27 (ppm), Cu<0.010wt.%, O: 42 (ppm), P: 40 (ppm), S: 36 (ppm), and the balance is iron.

[0025] The final heat treatment system of the martensitic steel is: normalizing 950-1100°C / 30min / air cooling+tempering 760-800°C / 100min / air cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com