Method for improving liquid metal corrosion resistance of martensite heat-resistant steel

A technology of liquid metal and heat-resistant steel, applied in metal material coating process, gaseous chemical plating, coating, etc., to achieve the effect of preventing oxidation and corrosion, ensuring stability and integrity, and high matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In this embodiment, the method for improving the liquid metal corrosion resistance of martensitic heat-resistant steel is as follows:

[0031] (1) Pretreatment of the metal surface: the metal sample with a diameter of 25mm and a thickness of 3mm is polished step by step to No. 2000 with metallographic sandpaper, and all edges and corners are rounded, polished, and ultrasonicated by alcohol and acetone Wash and tumble dry.

[0032] (2) The vacuum degree of the vacuum chamber of the double-hui plasma plating equipment is 5×10 -4 Pa, the mixed gas of high-purity hydrogen with a volume purity of 99.99% and tetramethylsilane with a volume purity of 99.99% is used as the reaction gas, and argon with a volume purity of 99.99% is introduced as the reaction gas as a protective gas to realize plasma excitation.

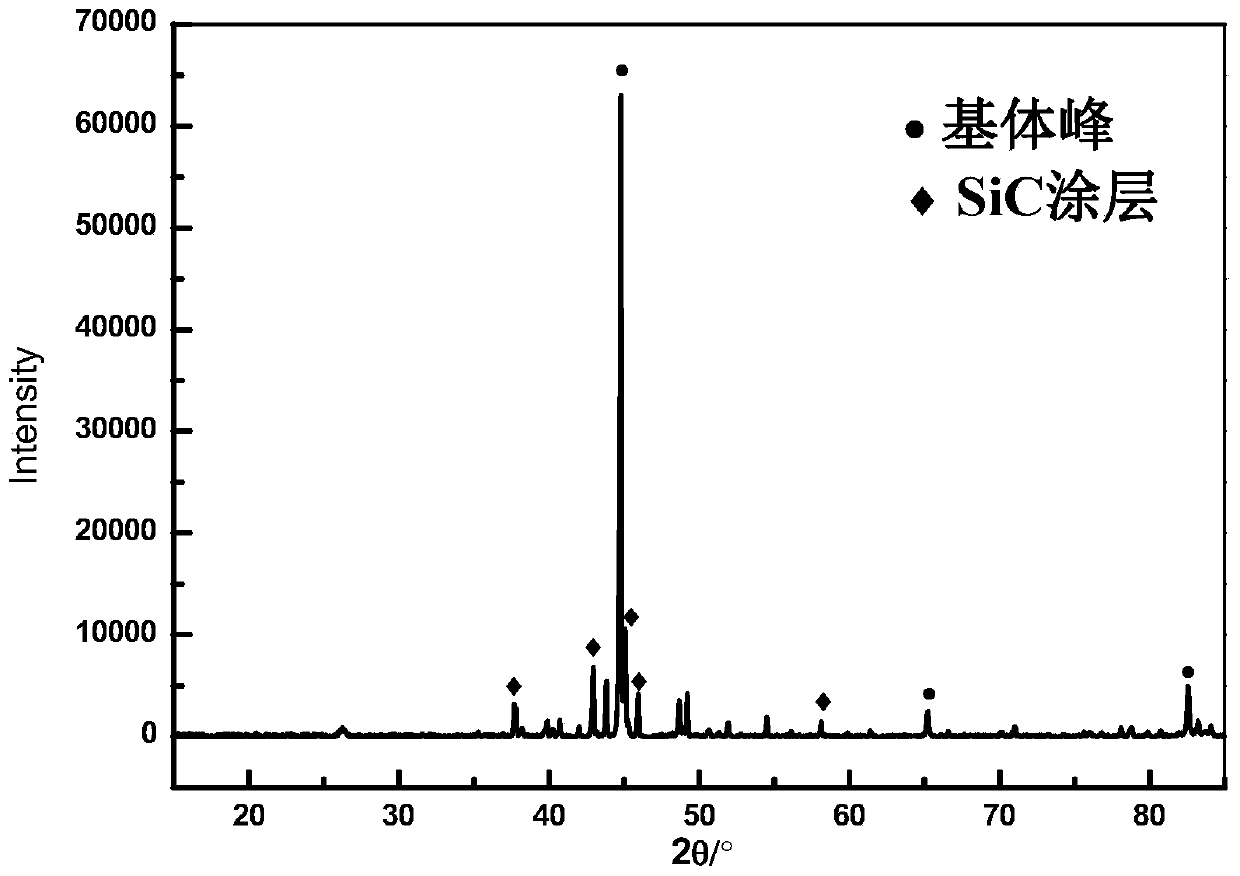

[0033] (3) Process conditions for preparing silicon carbide coatings on the surface of double-hui plasma: the flow rate of hydrogen is 15ml / min, and its partial pressur...

Embodiment 2

[0037]In this example, the chemical composition of the martensitic heat-resistant steel is: C: 0.08wt.%, Si: 0.05wt.%, Cr: 8.5wt.%, Mn: 0.45wt.%, W: 1.8wt.%. , Ta: 0.1wt.%, V: 0.1wt.%, Nb: 0.05wt.%, and the balance is iron. Other surface treatment processes of the metal are the same as in Example 1.

Embodiment 3

[0039] In this example, the chemical composition of the martensitic heat-resistant steel is: C: 0.32wt.%, Si: 0.5wt.%, Cr: 12.46wt.%, Mn: 1.41wt.%, W: 2.5wt.%. , Ta: 0.26wt.%, V: 0.35wt.%, Nb: 0.02wt.%, and the balance is iron. The metal surface treatment process is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com