Method of improving liquid metal corrosion resistance of martensite heat-resistant steel

A technology of liquid metal and heat-resistant steel, applied in metal material coating technology, ion implantation plating, coating, etc., can solve problems that restrict the sustainable development of nuclear power, achieve good radiation compatibility, ensure stability and Integrity, high matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In this embodiment, the method for improving the corrosion resistance of martensitic heat-resistant steel in the present invention is as follows:

[0024] (1) Pretreatment of the surface of the martensitic heat-resistant steel: grind the martensitic heat-resistant steel sample with a size of 15mm×10mm×2mm to No. 2000 step by step with metallographic sandpaper, and round all the edges and corners Corners, polished, ultrasonically cleaned in deionized water after cleaning with acetone and alcohol, and dried;

[0025] (2) During ion plating, the vacuum chamber is evacuated to the ultimate vacuum degree of 3×10 -3 Pa, then pass through the protective gas argon, load the negative bias voltage -800V, and perform glow cleaning for 10 minutes;

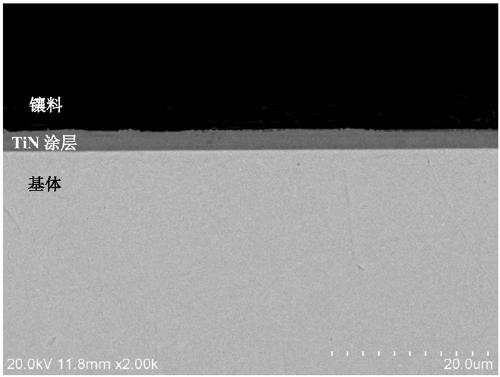

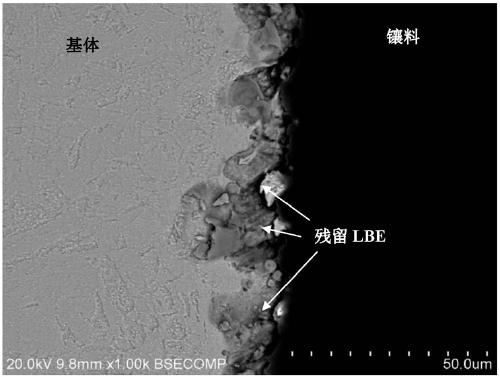

[0026] (3) The TiN coating is preset by arc ion plating, and the purity of the titanium target is above 99.9wt%. Coating parameters: Nitrogen partial pressure 4×10 -1 Pa, martensitic heat-resistant steel Apply negative bias -350V, tit...

Embodiment 2

[0030] In this embodiment, the method for improving the corrosion resistance of martensitic heat-resistant steel in the present invention is as follows:

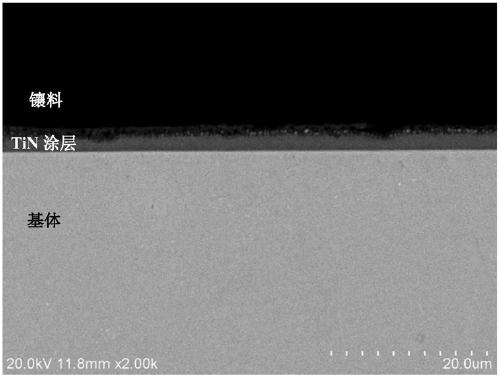

[0031] The chemical composition of 9-12% Cr martensitic heat-resistant steel is: C: 0.19wt.%, Si: 1.05wt.%, Cr: 10.05wt.%, Mn: 1.0wt.%, W: 1.19wt.%. , Ta: 0.1wt.%, V: 0.2wt.%, Nb: 0.01wt.%, and the balance is iron. Other surface treatment processes of the martensitic heat-resistant steel are the same as in Example 1.

Embodiment 3

[0033] In this embodiment, the method for improving the corrosion resistance of martensitic heat-resistant steel in the present invention is as follows:

[0034] The chemical composition of 9-12% Cr martensitic heat-resistant steel is: C: 0.15wt.%, Si: 1.23wt.%, Cr: 10.46wt.%, Mn: 0.41wt.%, W: 1.5wt.%. , Ta: 0.15wt.%, V: 0.19wt.%, Nb: 0.014wt.%, and the balance is iron. The surface treatment process of the martensitic heat-resistant steel is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com